Advanced energy management scheme for fuel cell-based

Nov 11, 2024 · Fuel cells are critical in providing sustainable energy solutions by enabling efficient energy conversion in microgrids. To enhance the performance of fuel cell-based microgrids,

Fuel cell 5kw inverter

Discover cutting-edge technology with fuel cell 5kw inverter solutions that offer clean, efficient, and sustainable energy. Ideal for businesses seeking to innovate and reduce carbon footprints.

A Grid-Tied Fuel Cell Multilevel Inverter with Low

Jan 29, 2021 · Fuel cell connections to utility grids require that the power conditioning units, interfacing the fuel cells and the grids, operate accordingly

Modernization of inverters for adaptation of hydrogen fuel

Dec 11, 2024 · As part of solving the problem of creating an autonomous source of alternating current electrical energy based on hydrogen fuel cells, the possibilities of preliminary

Novel High-Speed Turbo Compressor With

Feb 26, 2021 · Fuel cell technology is continuously gaining ground in E-mobility applications. Fuel cells require a constant supply of pressurized air, for which

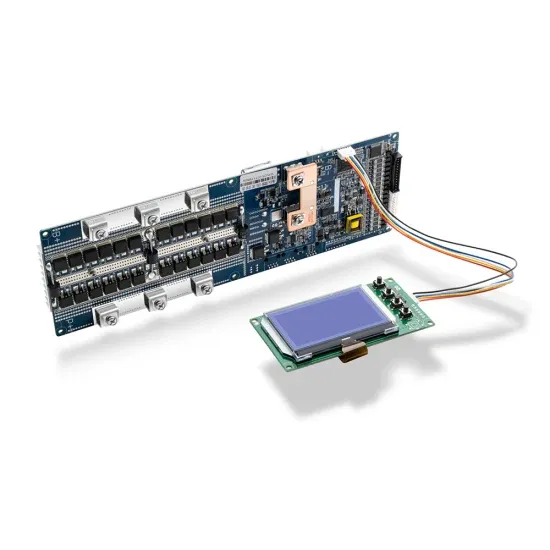

Power Electronics for Fuel Cell Systems: Boost Converters, Inverters

Jul 15, 2025 · Boost converters, inverters, and sophisticated energy management modules transform unstable fuel cell output into stable, usable power. They also protect both the fuel

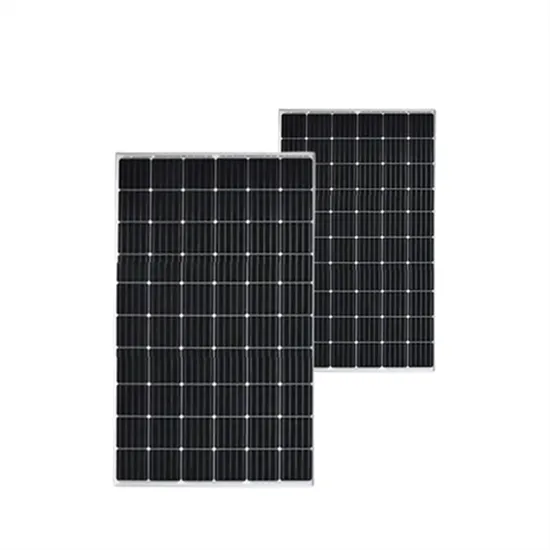

Frontiers | A grid-tied PV-fuel cell multilevel

Dec 8, 2022 · Hence, this paper aims to assess the performance of a centralized single-stage grid-tied three-level diode clamped inverter connected to a PV

Design and Implementation of Multilevel Inverters for Fuel Cell

Oct 6, 2020 · In this article, we develop an entire unit stack, which can produce an output with positive and zero sequences. The addition of H-bridge to the fundamental unit known to be an

Design and Implementation of Multilevel Inverters for Fuel Cell

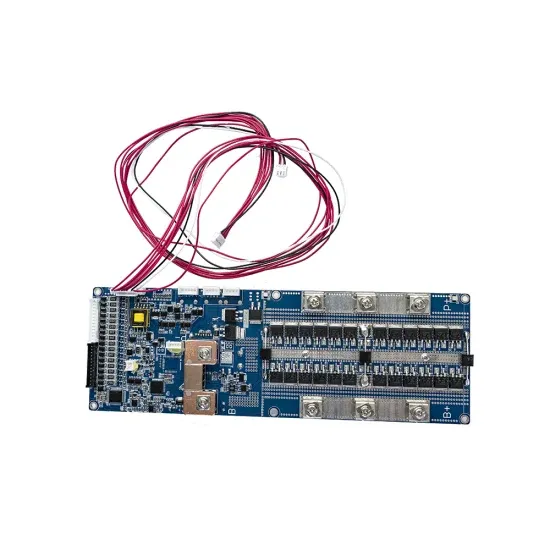

Oct 6, 2020 · Power converter plays a significant role in Proton Exchange Membrane Fuel Cell (PEMFC) energy generation systems, which is an alternative of distributed energy generation

Design and Implementation of Multilevel

Oct 19, 2020 · Power converter plays a significant role in Proton Exchange Membrane Fuel Cell (PEMFC) energy generation systems, which is an

Enhancing Distribution System Resiliency Using Grid

Apr 8, 2022 · These GFM inverters can use photovoltaics, batteries, or fuel cells as their energy source. In this paper, we present information on inverters interfacing fuel cell assets,

Comparison of Traditional Inverters and Z-Source Inverter for

Aug 23, 2013 · SYSTEM CONFIGURATIONS FOR FUEL CELL VEHICLEAs previously mentioned, three different inverter systems areto be investigated: the conventional PWM

Review of fuel cells to grid interface: Configurations,

Mar 10, 2019 · Fuel cell systems are connected to grid via different multilevel inverters The most well-known multilevel inverter topologies are cascaded H-bridge (Hamzeh et al., 2013), diode

Fuel Cell Energy Source Based Multilevel Inverter

Jun 4, 2021 · Abstract- This paper review analysis of the performance of a fuel cell energy source based Multi Level Inverter topology. Multi Level Inverter topologies are suitable in high power

Hyfindr Tech Talk #3

The inverter converts DC power from the fuel cell or battery into AC power, which is then used to drive the motor. Duroudier explains that there are different types of inverters for different

Validation of Interconnection and Interoperability of

Sep 11, 2023 · Run power hardware-in-the-loop experiment with grid-forming fuel cell (100kW) inverter and enable transition between grid-following and grid-forming modes of operation.

1 Comparison

Mar 16, 2024 · This document compares three different inverter topologies for use in fuel cell vehicles: a conventional pulsewidth modulation (PWM) inverter, a

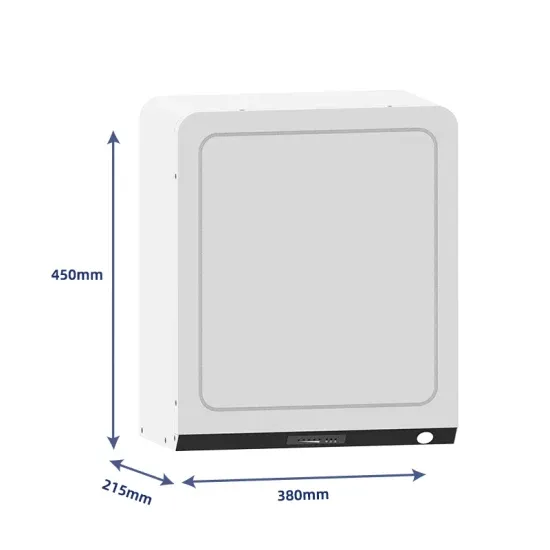

FUEL CELL PCS

2 days ago · The fuel cell inverters of G-Philos have varying designs to fit the input conditions that are required in various situations, depending on the type

Electrical Subsystem of Fuel Cells

Jul 25, 2017 · If you took the electrical output directly from a fuel cell, it would be an unideal power source. The output of a fuel cell is a DC voltage that varies

Fuel Cell Inverter Dataset | NREL Data Catalog

Dec 18, 2024 · Fuel Cell Inverter Dataset This data set contains the three phase AC voltage, three phase AC current, DC voltage and DC current. These data sets were captured during fuel cell

Validation of Interconnection and Interoperability of

Jul 16, 2024 · Interconnection and interoperability updates identified through this project will provide cost improvements for the utilities in the United States and increase the value of grid

Fuel-cell DC-DC boost converter

The fuel-cell DC-DC boost converter is an essential component in the functioning of fuel-cell electric vehicle drivetrain systems. In a fuel-cell electric drivetrain system, there is typically at

Inverters and Converters for Fuel Cell to Grid Power Conversion

In fuel cell to grid power conversion, Sécheron inverters excel at efficiently and reliably converting direct current (DC) from fuel cells into alternating current (AC) for grid integration. These

Grid connected fuel cell and PV hybrid power generating

May 27, 2014 · Output current and voltage of PV system was used for input of DC/DC boost converter and its output was used for the input of the inverter. PV system was connected to

2004-Comparison of traditional inverters and Z-source inverter

Nov 29, 2011 · SYSTEM CONFIGURATIONS As previously mentioned, three different inverter system configurations are to be investigated: the conventional PWM inverter, the dc/dc

Comparison of Traditional Inverters and Z -Source Inverter for Fuel

Aug 1, 2007 · In this paper, three different inverters: conventional pulsewidth modulation (PWM) inverter, dc-dc boosted PWM inverter, and Z -source inverter were investigated and compared

Energy Storage Inverters for Hydrogen Fuel Cells

Nov 2, 2021 · Hydrogen Fuel Cells Customizing needs for the growing clean energy market Driven by Dynapower''s deep commitment to powering the

FCEV powertrain system

Develop efficient fuel-cell electric vehicle (FCEV) powertrain systems with Infineon''s advanced solutions for hydrogen fuel-cell technology.

Fuel Cell Vehicle Auxiliary Inverter Solutions

Jan 28, 2019 · The T6 auxiliary inverter is used for fuel cell vehicle turbo compressor applications. It operates efficient PM servo motors without feedback.

fuel cell inverter, fuel cell inverter Suppliers and

Fuel cell inverters are vital components in the renewable energy market, acting as the bridge between the power generated by fuel cells and the electricity grid or local loads.

6 FAQs about [Inverter and fuel cell]

Can a DC/AC inverter be used for a fuel cell system?

For the 100kW fuel cell system, a 120kW power converter was selected. However, most commercially available grid-tie DC/AC inverters are not directly applicable to fuel cells due to their incorporation of specific features for maximizing power output from a variable solar input.

How does a fuel cell inverter work?

The inverter system must convert the fuel cell's output while accommodating inevitable changes in load and the response time of the fuel cells. The dc output of the cells varies with their load and age and with a polarization curve that is a function of the electrochemistry.

Does a grid-connected inverter store energy?

Abstract: This study introduces a grid-connected inverter powered by fuel cells (FC). Though comparable to a battery, the fuel cell does not store energy. DC voltage is continuously supplied to the fuel cell. Oxygen (O2)and hydrogen (H2) are used as fuel inputs.

Are high power grid-tied inverters suitable for fuel cell systems?

Commercially available high power grid-tied inverters are not suitable for fuel cell systems as they are primarily designed for photovoltaic (PV) systems. These inverters are designed to maximize solar power under varying insolation conditions.

Why is a fuel cell inverter so difficult to convert?

Still, you are dealing with a relatively low-voltage/high-current dc source, which makes it difficult to achieve electrical-conversion efficiency, especially over a wide load range. The inverter system must convert the fuel cell's output while accommodating inevitable changes in load and the response time of the fuel cells.

Are full bridge converters active front end for fuel cell inverters?

Depending on their input circuit, the converters are classified between voltage fed and current fed full bridge converter. In this paper, full bridge converters of the voltage type and of the current type as active front end for fuel cell inverters in the power range of 20 kW and higher are analysed and compared to each other.

Industry Information

- High quality factory price 225 amp breaker Wholesaler

- Do photovoltaic inverters have fans

- When will the Vienna energy storage power station be put into use

- Belarus photovoltaic energy storage policy

- Photovoltaic panels installed on the roof can generate electricity

- Best main circuit breaker in China Buyer

- 5kw inverter power supply in Barcelona Spain

- Palestine coal-to-electricity energy storage products

- New Zealand photovoltaic panel manufacturer

- 50kw inverter control power supply

- Cheap factory price 3000w inverters Seller

- Lubumbashi Energy Storage Microgrid in the Democratic Republic of Congo

- Base station power distribution cabinet manufacturers

- Tokyo battery storage box price

- Funafuti energy storage lithium battery manufacturer customization

- Transmission optical fiber of battery energy storage system for communication base station

- The quality of Bulgaria s new industrial and commercial energy storage equipment

- Ecuador photovoltaic energy storage wholesale

- Boston ups uninterruptible power supply battery price

- Customized mobile energy storage power supply method

- Current price of photovoltaic inverter

- Solar 48v system

- 100kw solar inverter in China in Kenya

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.