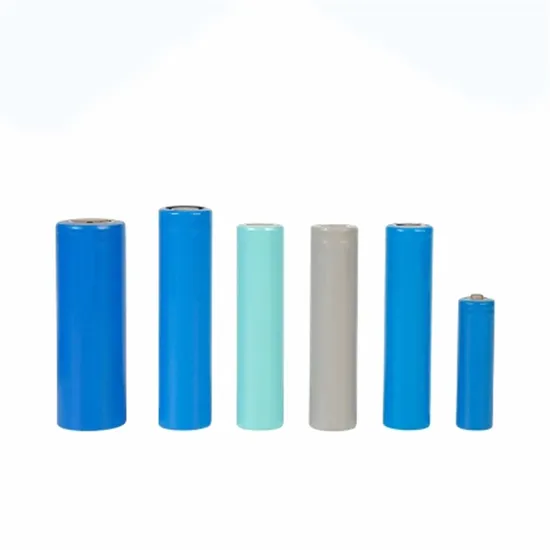

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Lithium-ion batteries (LIBs) have become one of the main energy storage solutions in modern society. The application fields and market share of LIBs h

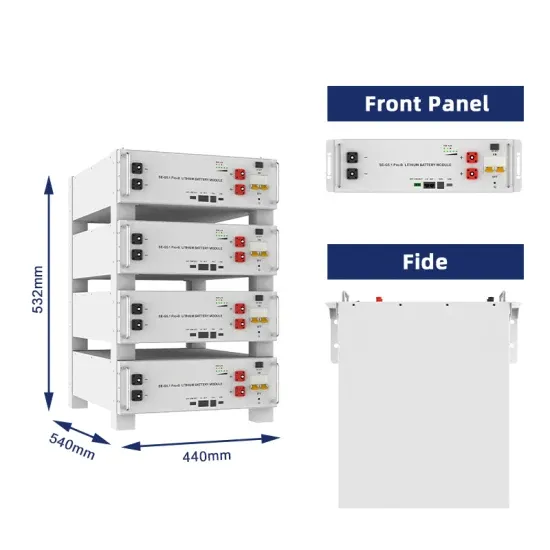

Battery Pack Automated Assembly Production Line

Our automated battery pack assembly line is highly standardized and suitable for over 90% of cylindrical battery products on the market. It features unique

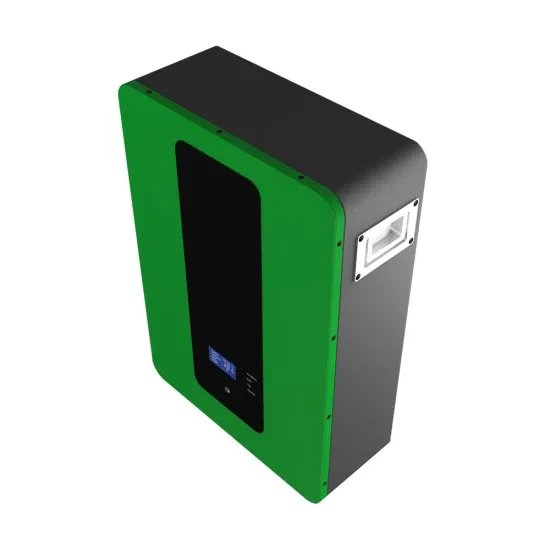

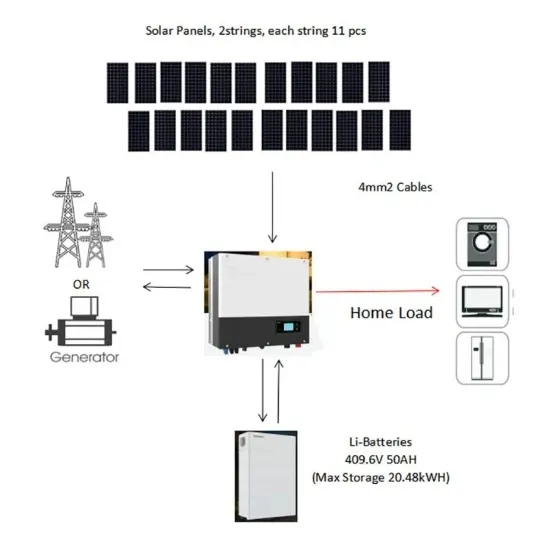

Power Battery Energy Storage System (BESS)

1 day ago · The application range of lithium battery module assembly production line is very wide,including electric vehicles, energy storage equipment,solar

The Manufacturing Process of Lithium Batteries

Lithium battery manufacturing encompasses a wide range of processes that result in the production of efficient and reliable energy storage solutions. The

Battery Manufacturing Equipment Providers

Aug 3, 2025 · Battery manufacturing equipment refers to the specialized machinery used in the production of battery components and their assembly into finished cells. This technology is

lithium-ion battery production lines

Aug 16, 2025 · Our product portfolio starts after cell production and covers module and pack assembly for lithium-ion or sodium-ion batteries. We are

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

With the right machines and equipment, it''s possible to elevate your processes and drive change, for example with the development of cutting-edge electric vehicles. We also offer battery

What are the energy storage battery production equipment?

Aug 27, 2024 · 2. The primary types of equipment include electrode manufacturing machinery, cell assembly lines, and advanced testing systems. 3. Each type of equipment is essential for

Huiyao Laser Equipment Lithium Ion Battery Pack Assembly

Aug 3, 2025 · Lithium battery module fully automatic assembly line is mainly used in the production of new energy lithium battery modules, Prismatic battery modules, energy storage

ETN News | Energy Storage News | Renewable

3 days ago · ETN news is the leading magazine which covers latest energy storage news, renewable energy news, latest hydrogen news and much more.

New Energy > Battery production technology | BBS

3 days ago · Together with our customers, we develop production systems for battery modules from a variety of cell designs. We also develop systems for the end-of-line testing of battery

New Energy Automation

1 day ago · With over a decade of experience in developing manufacturing equipment and delivering high-standard, intelligent projects for global clients,

Optimize Battery Assembly Line with Design and

4 days ago · Scaling your battery production for EVs and energy storage systems takes more than just equipment; it takes smart design and reliable automation.

Assembly line for battery modules and battery packs

3 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Battery production process and equipment

6 days ago · Lithium battery equipment plays a key role in the continuous improvement of lithium battery production technology, lithium battery yield and

Top 10 lithium battery production equipment

Jul 29, 2023 · The main products include lithium battery production equipment, new energy storage and new Energy control equipment, water treatment

Advanced lithium-ion battery process manufacturing equipment

Jul 18, 2025 · Summary Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and

Module and PACK Line (Energy Storage

The equipment has the advantages of automatic intelligent assembly and production from prismatic aluminum shell cell to module and then to PACK

Battery Machines for lead-acid and lithium-ion

6 days ago · With our machines, you can assemble lead-acid automotive, motorcycle, industrial traction, and stationary batteries as well as lithium-ion

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · Conclusion The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality,

Shanghai Zonzsin Intelligent Equipment Co., Ltd.-Power Battery

Shanghai Zonzsin Intelligent Equipment Co., Ltd. focuses on serving the power battery, energy storage system industry and photovoltaic industry, providing customers with professional

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The world has been rapidly moving towards renewable energy sources, and batteries have emerged as a crucial technology for this

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

We also offer battery manufacturing machines to enhance the production and assembly of stationary energy storage solutions, mobile devices, wind turbines, and solar panels.

HuiYao Intel

Our production line for prismatic battery modules stands out for its ability to meet the growing demands of the energy storage market. By prioritizing this sector, we aim to provide reliable

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy storage

Advanced lithium-ion battery process manufacturing equipment

Jul 18, 2025 · Manufacturing equipment evaluation highlights significant challenges in electrode preparation, cell assembly, and finishing. Using space-saving machinery and cost-effective,

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · Lithium-ion Battery Module and Pack Production Line Process Flow The lithium-ion battery module and pack production line is a complex

Battery Equipment Solutions for Cell

5 days ago · Commercial manufacturing and R&D Battery Equipment solutions for lithium-ion battery, supercapacitor and energy storage system manufacturers.

Battery energy storage systems | BESS

3 days ago · Battery energy storage (BESS) offer highly efficient and cost-effective energy storage solutions. BESS can be used to balance the electric

Prismatic Battery Pack Assembly Line

The Prismatic Battery Pack Assembly Line integrates a variety of automated equipment and technologies, mainly covering the entire process from module assembly to the final battery

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Introduction Energy storage market is on rise across the world. Every company, new or old, that is in the field of renewables or electric vehicles, is looking for even more

6 FAQs about [Energy storage battery assembly production equipment]

How can a local battery manufacturing system help a battery plant?

Local manufacturers will scale up and cover the entire machinery for a battery plant through collaborations, from producing electrodes to the final cell formation. Localizing innovation and equipment manufacturing will build a sustainable and competitive battery manufacturing system.

How can a battery production line be sustainable?

Innovations such as simultaneous cell formation processes, seen in companies like Tesla and Panasonic, exemplify how global manufacturers are optimizing battery production lines to meet the demands of electrification and sustainable energy storage worldwide. - Equipment manufacturing can rely on green production.

Why should you choose our automated battery pack assembly line?

Our automated battery pack assembly line is highly standardized and suitable for over 90% of cylindrical battery products on the market. It features unique double-sided cross spot welding equipment for one-time welding, reducing costs and simplifying ope

What is the future of battery manufacturing?

More compact, multifunctional machines can transform battery production, making it more efficient in terms of space, cost, and scalability. The future of battery manufacturing will see increased integration of space-saving equipment and advanced formation processes that reduce production time and costs.

Is battery manufacturing sustainable?

Sustainability in battery manufacturing is not limited to any region but is a universal goal. Across the globe, from Asia to Europe and the Americas, manufacturers are adopting green energy, solvent-free processes, and recycling technologies to minimize environmental impact.

Are GWh-scale battery production systems a viable solution to the Lib demand surge?

Most of the developments in battery production target GWh–scale production systems to meet the global LIB demand surge, especially in EV and stationary storage applications.

Industry Information

- Vietnam energy storage project scale

- Is the outdoor lithium battery station cabinet safe

- Which photovoltaic battery assembly is better

- Photovoltaic energy storage power generation charging pile

- Energy storage on the grid in Brazil

- Asia foldable photovoltaic panel manufacturers

- Brunei lithium battery battery pack

- How long does it take to charge the battery at the energy storage cabinet site

- What is the price of rooftop photovoltaic energy storage

- Three modes of energy storage power station

- Price of energy storage equipment for 30 000 kWh of electricity

- High-power AP outdoor base station installation

- Hot sale high quality 240 volt breaker producer

- Bahamas Mobile Generator Station

- Pwm inverter and voltage source inverter

- Wind Solar and Storage Project Integration

- How much is an outdoor communication battery cabinet in Eritrea

- Energy storage battery station cabinet is

- Application for acceptance of uninterrupted power supply for communication base stations

- 1000kwh energy storage system in Mozambique

- Africa s outdoor power supply factory

- High quality thermal breaker in Ukraine

- How much does electricity storage cost per kilowatt-hour

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.