BATTERY CABINET LOAD BEARING SCHEME DESIGN

FAQs about Nickel-zinc battery production line design specifications What is a nickel zinc battery? A nickel–zinc battery (Ni–Zn battery or NiZn battery) is a type of rechargeable battery similar to

Fire Alarm Battery Calculator | NFPA 72

Apr 15, 2025 · Calculate required fire alarm battery capacity according to NFPA 72 (US) or BS5839 (UK/Europe) standards. Determine the correct battery size

Kitchen Cabinets Maximum Load Carrying

Oct 19, 2017 · In this study, the maximum load carrying capacity of wall kitchen cabinets structure were investigated. Factors such as material types, wall

Battery Cabinets | Racks | Heavy Duty | Singapore

Aug 19, 2025 · Singapore based manufacturer of Electronic Enclosures, Outdoor Cabinets, Network Racks, Gas Cabinets, Battery Cabinets, Digital Signage Enclosures and Kiosks, Ipad

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · To calculate the minimum height of the cabinet, use the general formula above. Example (illustrated on left): Rack height = 10" Battery height = 19" Charger = 25"

How to Calculate Heat Load in

Aug 5, 2019 · Total heat load consists of the heat transfer from outside your panel and from the heat dissipated inside the control unit.

Battery Capacity Calculator

If you want to convert between amp-hours and watt-hours or find the C-rate of a battery, give this battery capacity calculator a try. It is a handy tool that helps

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, such as solar and wind,

Floor Loading: The Ultimate Guide to Safely

Load Weight and Capacity Understanding the weight of the floor loaded items to be placed and the floor''s load-bearing capacity significantly influences the

Battery Sizing Considerations IEEE 2020

Mar 11, 2020 · Batteries provide DC power to the switchgear equipment during an outage. Best practice is to have individual batteries for each load/application. *Lead-Acid has a minimum

Basics of Load Calculations in Structural Design

May 21, 2022 · Perhaps the first thing for the Structural Engineers to be aware of in their structural design is the assumptions and consideration of the design

Battery Sizing Calculation | Solved Example

3 days ago · Learn about battery sizing calculation for applications like Uninterrupted Power Supply (UPS), solar PV systems, telecommunications,

Structural Load Calculations

Jul 9, 2025 · Summary of design load calculations and combinations as presented in AS/NZS 1170:2002, ASCE 7-10 and EN 1991-1-1.

Design of a Battery Cabinet for Electric Scooters to Facilitate Battery

May 11, 2023 · Hence in this work, a new battery cabinet design is proposed that can securely contain the battery and enable quick, toolless battery removal for easy battery swapping. This

Battery Capacity

Jul 23, 2025 · Ampere-hour (Ah): This unit of battery capacity represents how much current battery can provide for 1 hour. For example, a battery with a

Battery Load Calculation

Mar 18, 2025 · The process also integrates battery-specific parameters such as voltage, amp-hour capacity, and depth of discharge to provide an accurate sizing recommendation. Key Formulas

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

Dynamic mechanical behaviors of load-bearing battery

Apr 29, 2024 · 本文通过实验和数值研究了集成结构在常见的低速冲击事件下的动态响应和失效机制。 通过实施组件材料的本构模型开发了宏观有限元 (FE) 模型,包括锂离子聚合物 (LiPo) 电

Dynamic mechanical behaviors of load-bearing battery

Sep 1, 2024 · To better illustrate the performance of the integrated load-bearing battery structures and facilitate lightweight design, two additional constructions were designed for comparison:

SECTION 6: BATTERY BANK SIZING PROCEDURES

Jun 14, 2022 · Total energy (actually, charge) required by the load over the autonomy period is the area under the curve Sizing procedures map the load profile to a battery capacity capable

NTN Technical Information Series PDF''s

Mar 30, 2025 · 6.1 Loads acting on shafts To compute bearing loads, the forces which act on the shaft being supported by the bearing must be determined. These forces include the inherent

How to calculate the battery cabinet occupied by single

Time. To calculate the battery run time, follow these steps: 1. Determine Battery Capacity: The capacity of a battery is u ually measured in ampere-hours (Ah) or milliampere-hour

*4. 2 ó × d Ì v Z

Jan 7, 2018 · 4. Bearing Load Calculation To compute bearing loads, the forces which act on the shaft being supported by the bearing must be determined. Loads which act on the shaft and its

How to Calculate Load Capacity Of Racks?

Oct 4, 2024 · How to Calculate Load Capacity Of Racks? This Excerpt seamlessly integrates the key points of the article while highlighting the

Dynamic mechanical behaviors of load-bearing battery

Request PDF | On Apr 1, 2024, Ruiqi Hu and others published Dynamic mechanical behaviors of load-bearing battery structure upon low-velocity impact loading in electric vehicles | Find, read

How to Calculate Load-Bearing Capacity of Flat

Dec 10, 2024 · Calculating the load-bearing capacity of flat bars is a fundamental skill for engineers and designers involved in structural applications. A flat bar,

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Data center design standards for cabinet and floor loading

Jun 29, 2011 · Heavy equipment can stress floor structures, making floor loading capacity and cabinet weight a critical data center design concern.

Battery cabinet bracket and load-bearing frame

Optimization design of battery bracket for new energy vehicles Serving as the primary component responsible for carrying and protecting the power battery, the battery bracket fulfills

How to calculate the heat dissipated by a battery pack?

Aug 22, 2018 · I have a battery pack consisting of 720 cells. I want to calculate the heat generated by it. The current of the pack is 345Ah and the pack voltage is 44.4Volts. Each cell has a

Kitchen Cabinet Weight Limits: How Much Can

Jul 11, 2025 · The Kitchen Cabinet Manufacturers Association (KCMA) sets a standard for cabinets to hold up to 600 pounds. Most cabinet manufacturers

6 FAQs about [Battery cabinet load-bearing formula]

How does battery arrangement affect load-deformation curves?

The battery arrangement affects the load-deformation curves as the mechanical integrity in width and length direction is altered. Both Model W and Model L exhibit permanent plastic deformation at the end of impact events. Fig. 6.

Does polymer foam improve energy absorption capacity of lithium-ion batteries?

The integration of lithium-ion battery with composite laminate increased the energy absorption capacity by 57 %, attributed to its high deformability. The introduction of polymer foam significantly improved the energy absorption density while not affecting much the impact resistance.

How are battery capacities and discharge ratings calculated?

Battery capacities and discharge ratings are published based on a certain temperature, usually between 68oF & 77oF. Battery performance decreases at lower temperatures and must be accounted for with correction factors. factor applied at the end of the calculation. – NiCad – Temperature correction factor applied at each step in the calculation.

What are the mechanical properties of lithium-ion batteries?

The mechanical properties of lithium-ion batteries have been measured under various loading conditions, such as in-plane and out-of-plane compressions [6, 12, 18], punch indentation [19, 20], nail penetration [7, 21], bending [22, 23], tension , and impact events .

How FE models are used in energy storage and load-bearing structures?

The FE models, which validated the experimental results, were also used to reveal the related mechanisms, and facilitate the future design of such energy storage and load-bearing structures. The paper is constructed as follows: Sec.2 demonstrates the material properties and the experimental setup. Sec.3 presents the numerical approach.

What is the value of internal battery resistance?

to the ratio between the full-charge voltage at battery terminals and the internal battery resistance. The value of the internal resistance depends on the cell’s geo etry and construction and on the operating conditions. The common resistance range is 0.5-10 mΩ/cell.From a safety perspective,

Industry Information

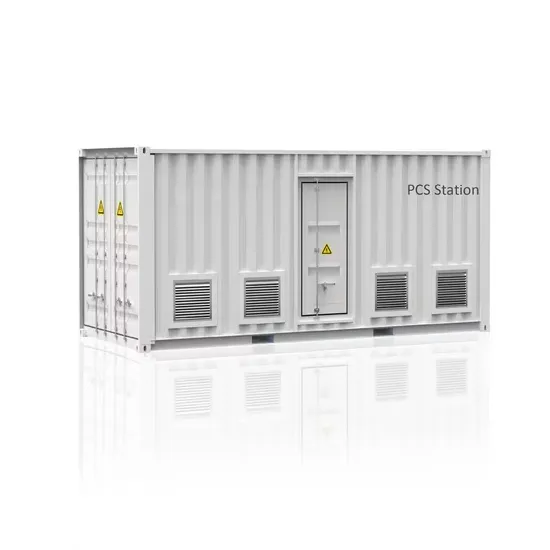

- Rome III Energy Storage Project

- Dubai energy storage equipment brand

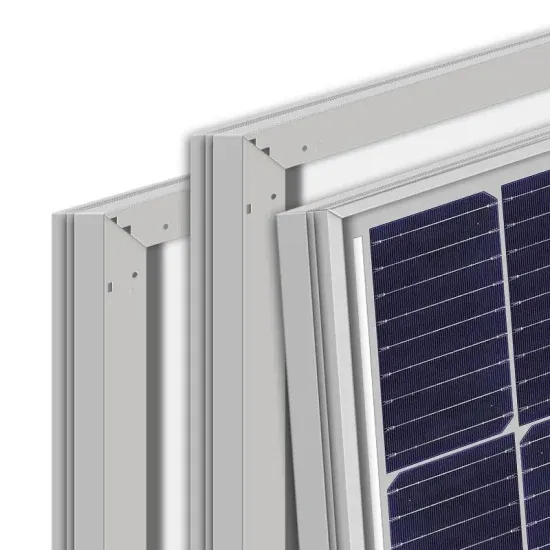

- Flexible photovoltaic panel crystalline silicon

- Voltage source inverter impedance

- How to identify energy base stations in communications

- Is portable power useful for batteries

- Photovoltaic panel model size and dimensions

- Battery pack is widely used

- Solar power solutions factory in Guinea

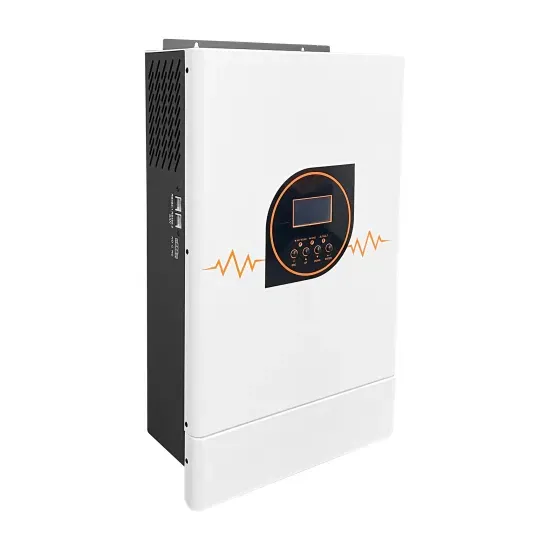

- Industrial and commercial photovoltaic grid-connected energy storage integrated machine

- Madrid 5G communication base station battery energy storage system bidding

- Photovoltaic AC combiner box structure

- Can the high voltage bar be used to change the inverter

- How much does the battery cabinet detection needle cost

- Chemical energy storage unit cost

- Generator container dimensions and specifications

- Solar lighting system installation in Norway

- Independent energy storage frequency regulation power station

- Majuro Huidong invests in energy storage cabinet batteries

- Small energy storage vehicle accessories price

- Building photovoltaic integration requires energy storage

- Porto Novo Environmentally Friendly Energy Storage Power Company

- Photovoltaic curtain wall price for shopping malls in Cebu Philippines

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.