Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · Battery cell assembly is one of the key steps in the lithium battery module PACK production line. First, the battery cells are combined with

Lithium Battery Assembly: How to Build Battery

Feb 22, 2024 · How to build a lithium battery? Our simple, step-by-step guide walks you through the process. Dive into this beginner project today!

Battery Pack Assembly: From Cells to Power Packs

Discover how individual battery cells become high-performance battery packs. Learn about cell connection, modularization, and the critical role of battery

Design for Assembly and Disassembly of Battery Packs

Aug 23, 2019 · Based on the evaluation, an "ideal" battery is developed with focus on the hardware, hence the housing, attachment of modules and wires, thermal system and battery

Innovating battery assembly

Aug 13, 2025 · EV batteries have become an integral part of the vehicle structure, making lithium-ion cell assembly and their integrity a safety-critical issue. One major diferentiating feature of

Battery Pack Assembly : 5 Steps

Battery Pack Assembly: The goal of this project is to create a battery pack from purchased power cells. Is important to understand how cells can be connected

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Battery Management IC

ST''s portfolio of battery management ICs includes battery monitoring fuel gauge ICs, battery charger ICs and thin-film rechargeable solid-state batteries

Small cylindrical lithium pack automated assembly

May 30, 2025 · Previous: Small cylindrical lithium pack automated assembly line(BCYA-L05GE) Next: Automatic assembly line for big cylindrical lithium battery packs(BCYA-L02F)

EV Car Battery Assembly,Electric Bike Battery Assembly

We also supply all kinds of EV Car Battery Assembly,Electric Bike Battery Assembly for you! We can assure our customers of our products with high quality,best services and a reasonable price.

Custom Battery Packs & Assemblies | Power Solutions

For over 57 years, Custom Power has designed, developed, and manufactured high-quality, reliable, custom battery packs. We provide battery pack assemblies in all chemistries,

New Small Cylindrical Lithium Battery Packs Automatic Assembly

Shenzhen benice Technology Co., Ltd. is a national high-tech enterprise integrating R&D, manufacturing, sales and technical services. Founded in Shenzhen in 2010, it focuses on

Lithium Battery Module Pack Assembly Line

Our battery module and pack assembly lines are designed with flexibility and scalability in mind, supporting custom configurations for both small-batch prototyping and high-volume mass

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Comprehensive Guide to Battery Assembly

Jun 18, 2024 · Battery assembly combines cells and connectors to create functional batteries. Using precise tools and steps ensures proper functionality

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Battery Pack Assembly: Techniques and

Nov 27, 2024 · This article delves into the techniques and materials used in battery pack assembly, emphasizing their importance in the broader EV and

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production. In this article, we will explore the world of battery

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · Explore the Lithium-Ion Battery Assembly Line —how precision, automation, and testing ensure high performance, safety, and reliability in

Battery Module & Pack Manufacturing: Step-by

Apr 19, 2025 · As India and other emerging markets ramp up battery pack assembly, the global blueprint is clear: automation, flexibility, and integrated

Beginner-Friendly Tips for Assembling Lithium

May 7, 2025 · Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Intelligent Production Line For Energy Storage Battery Pack

Lithium Battery Assembly Automation Production Line The assembly line has realized the automation of the whole process of battery and module loading, sorting, assembly, welding,

(PDF) Material selection and assembly method

Jan 1, 2018 · Therefore, this work presents Decision Matrix, which can aid in the decision-making process of component materials and assembly methods for a

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The production process of a lithium-ion battery cell consists of three critical stages: electrode manufacturing, cell assembly, and cell finishing.

Assembly line for battery modules and battery packs

4 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Battery Pack Manufacturing Process: Step-by-Step Guide

Dec 2, 2024 · Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

High-Performance Intelligent Lithium Battery Module PACK Assembly

Summary: This is a large-scale and intelligent module PACK assembly line, the cycle time of which can reach 16 PPM, meeting your requirements of large-scale, multi-batch and high

Industry Information

- How many types of energy storage batteries are there in Port Moresby

- Muscat Terrace Photovoltaic Glass Production

- Is the energy storage system on the DC side

- Models of energy storage batteries imported from Libya

- Total number of solar cells in Podgorica

- Energy storage cabinet batteries can be charged

- Kiribati Converter Photovoltaic Inverter

- 380v charging portable AC power box

- Transparent solar tiles

- Nordic phase change energy storage equipment

- Ashgabat Central Inverter Manufacturer

- Dominican rooftop photovoltaic panels

- Cheap high quality 1000 va inverter Factory

- Abuja communication base station wind and solar complementary project bidding

- Chile 5v photovoltaic panel wholesale price

- Warsaw energy storage battery box manufacturer

- Dubai Mobility and Battery Storage

- China high tension switchgear in Gambia

- Factory energy storage equipment manufacturers

- Price of 50 kWh energy storage cabinet

- China bolt on circuit breaker in Mumbai

- Iceland lithium battery bms manufacturer

- 5kw sunsynk inverter in China in Australia

Commercial & Industrial Solar Storage Market Growth

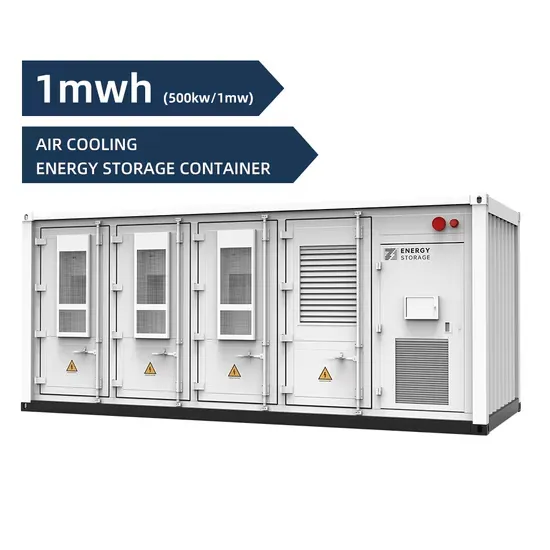

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

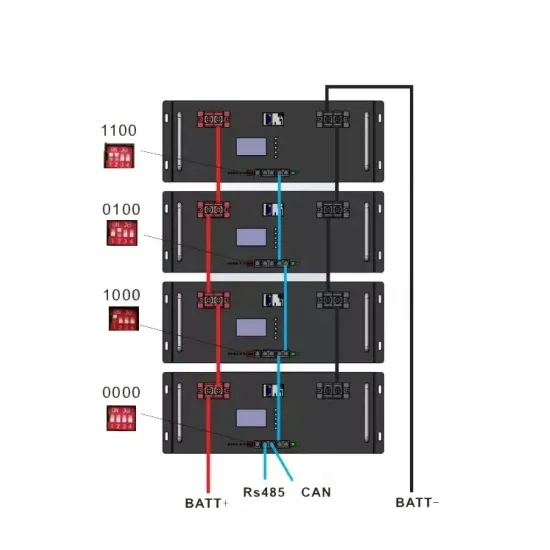

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.