New Energy Battery Vibration Test System With

New Energy Battery Vibration Test System With Large Vertical Table And Slip Table Vibration testing is crucial for ensuring the reliability and safety of new

Finite Element Analysis and Structural Optimization Research of New

Dec 1, 2023 · Abstract This study takes a new energy vehicle as the research object, establishing a three-dimensional model of the battery box based on CATIA software, importing it into

Mechanical vibration''s effect on thermal management

Aug 1, 2024 · As the pivotal component of EVs, the power battery distinguishes itself from traditional fuel vehicles, and its performance will directly affect the whole vehicle''s performance

Battery Vibration: Everything You Need to Know to Avoid Battery

3 days ago · Nowadays, batteries play a crucial role in various sectors, ranging from electric vehicles to large-scale energy storage systems. However, behind their growing performance

New energy battery vibration test principle

The growing trend for electric vehicle (EV) technology brings with it new challenges in the design and simulation of automotive drivetrains. In particular, the noise, vibration and harshness

How about new energy storage cabinet | NenPower

Jun 1, 2024 · 1. INNOVATIVE TECHNOLOGY The landscape of energy storage has witnessed a profound transformation, thanks in large part to the advent of new energy storage cabinets.

Jtam-A4.dvi

Jan 13, 2024 · For new energy vehicles, the key component that affects vehicle safety is the battery pack. As the carrier of the battery, the importance of the battery pack cannot be

Sinopoly, FAW and State Grid Join Hands to

In today''s rapidly developing new energy vehicle market, Sinopoly, FAW and State Grid have reached a strategic cooperation to jointly explore the

Cell geometry influences on the vibration performance of

Feb 15, 2025 · Lithium-ion batteries are rechargeable energy storage systems in which lithium ions travel between negative and positive electrodes during charging and discharging [1]. In

Mechanical vibration modeling and characterization of a

Sep 1, 2022 · By analyzing the mechanical structure of the battery, the first principles modeling method is selected to model the battery''s mechanical performance. The vibration data in the

New energy electric vehicle battery health state prediction

Jan 15, 2024 · The health status of the battery of new energy electric vehicles is related to the quality of vehicle use, so it is of high practical application value to predict the health status of

What Are Telecom Battery Cabinets and How Do They

Jul 10, 2025 · Telecom battery cabinets are specialized enclosures housing backup batteries that provide uninterrupted power to telecommunications infrastructure during outages. They ensure

Benchtop Vibration Table

The TCB-1.3 benchtop vibration chamber is ideal for reliability testing of compact products and electronics. It may be used as a stand-alone vibration table for

EV Battery Testing

Jul 12, 2023 · Electric MAST table (Multi-Axial Simulation Table) for 6 degrees of freedom vibration testing - delivering faster response, higher frequency and enhanced eficiency

Jtam-A4.dvi

With the rapid growth in new energy vehicle industry, more and more new energy vehicle battery packs catch fire or even explode due to the internal short circuit. Comparing with traditional

Shaker Systems & Vibration Testing Solutions

Aug 19, 2025 · Discover top-quality shakers & accessories designed for precise and reliable vibration testing. Enhance your testing capabilities with our

Large EV Battery Vibration Testing | MTS Systems

The Model 354 LG (Large-Geometry) Multi-Axial Simulation Table is purpose-engineered to support a full spectrum of vibration testing of lithium-ion battery packs used in electric

New energy battery high frequency

The electromagnetic vibration testing machine is completely designed according to the relevant testing standards of batteries. It simulates the battery to be

Evaluation of the safety standards system of power batteries

Nov 1, 2023 · This paper next proposes rationalization suggestions for the update and improvement of a Chinese battery standards system from three aspects—different levels of

General overview on test standards for Li-ion batteries,

Nov 7, 2017 · This table covers test standards for Li-ion batteries. It is made in the European projects eCaiman, Spicy and Naiades. batterystandards

Vibration Tables Customized Lithium Ion Battery

Aug 7, 2025 · Vibration Tables Customized Lithium Ion Battery New Energy, Find Details and Price about Battery Table Vibration Tables from Vibration Tables

The Ultimate Guide to Vibration Testing for EV

Sep 11, 2024 · The power battery system is the core component of electric vehicles, and its reliability directly affects the safety and reliability of the entire

Battery cabinets prevent and reduce the risk of lithium batteries

To address this issue, manufacturers have developed a new type of safety equipment: battery storage cabinets, also known as lithium-ion battery charging and storage cabinets, designed to

Battery cabinet for safely charging lithium-ion

Charge your lithium-ion batteries safely in a battery cabinet | Batteryguard contains battery fires within the safe | European tested and approved

Battery Cabinet Vibration Testing | HuiJue Group E-Site

When was the last time you considered how battery cabinet vibration testing prevents catastrophic failures in renewable energy systems? As global energy storage deployments surge – up 68%

New Energy Lithium Battery Cabinet Vibration

Effect of dynamic loads and vibrations on lithium-ion batteries Lithium-ion batteries are being increasingly used as the main energy storage devices in modern mobile applications, including

BYD Energy

Aug 6, 2025 · Standard outdoor battery cabinet, MC Cube-T uses the new-generation LFP battery for energy storage, and adopts the world''s first CTS (Cell To System) integration technology,

New Energy Battery Vibration Test System With Large Vertical Table

Vibration testing is crucial for ensuring the reliability and safety of new energy batteries. As batteries are increasingly being used in various applications, including electric vehicles and

Battery – Green Building New Energy

BESS Cabinet 344 kWh Liquid-cooled battery storage system based on HiTHIUM prismatic LFP BESS Cells 280 Ah with high cyclic lifetime Improved safety characteristics and specially

The Ultimate Guide to Vibration Testing for EV

Sep 11, 2024 · Vibration testing is an essential method for assessing the mechanical reliability of power battery systems. This article primarily

Vibration Tables / Vibration Tables

The test item is placed on the table top, and the table is then subjected to a series of vibration tests to simulate the conditions that the device may experience in its intended operating

New Energy Storage

Ecube L - Liquid Cooling Energy Storage Cabinet Back Technical advantages • Flexible Deployment: Modular energy cabinet, flexible expansion, IP55 to

Energy Storage Cabinet Vibration | HuiJue Group E-Site

When energy storage cabinets start humming at 2 AM in a power plant, is it a sign of efficient operation or a ticking time bomb? Recent field data from California''s grid infrastructure reveals

6 FAQs about [New Energy Battery Cabinet Vibration Table]

How a power battery system is fixed to a vibration table?

Power battery systems are usually fixed to the vibration table using specially designed fixtures. The main function of the fixtures is to secure the sample to the table and transmit the vibration load from the table to the test sample without distortion.

What type of vibration table is used for vibration testing?

Vibration testing is generally conducted using a vibration table, which can be mechanical, hydraulic, or electric. Electric vibration tables are the most widely used, with a broad working frequency range, good vibration waveform, and easy control and operation, generally meeting the requirements for vibration tests above 2Hz.

What are the standards for vibration testing of battery systems?

Most testing standards for battery systems include vibration tests. The national mandatory standard GB38031 ⇱, issued in 2020, clearly defines the methods and requirements for vibration testing of power battery systems. The relevant standards for vibration testing of battery systems in both domestic and international contexts are as follows:

What is vibration testing of power battery systems?

Vibration testing is an essential method for assessing the mechanical reliability of power battery systems. This article primarily introducing the vibration testing methods of power battery systems. 1. Vibration Testing 2. Comparison of Battery System Vibration Standards 3. Vibration Testing of Power Battery Systems 1. Vibration Testing

How reliable is a power battery system?

The power battery system is the core component of electric vehicles, and its reliability directly affects the safety and reliability of the entire vehicle. During vehicle operation, the power battery system is constantly subjected to vibration loads, making vibration resistance an important evaluation criterion.

What is a vibration test for lithium batteries?

UN 38.3 is primarily used to simulate the vibration loads experienced by lithium batteries during transportation. The vibration test in this standard is conducted with sweep-frequency vibrations in the X, Y, and Z directions, and the vibration test level varies depending on the weight of the sample (12kg).

Industry Information

- Uganda base station power cabinet manufacturer

- 40W Solar Configuration

- A-grade 21700 battery cells

- Ljubljana solar off-grid 10kw inverter

- Nordic capacitor energy storage solution

- Cooperation with energy storage container manufacturers

- Georgia s new mobile energy storage power supply

- Energy storage battery cabinet manufacturers

- Mbabane Outdoor Communication Battery Cabinet System

- Luanda Wind and Solar Energy Storage Power Generation Project

- Outdoor power supply customized structure

- Best 1000w solar inverter in China Factory

- Pyongyang energy storage battery manufacturer

- Thin-film photovoltaic panel structure manufacturer in Osaka Japan

- Future Industrial-grade Outdoor Power Supply

- Monaco photovoltaic energy storage subsidies

- Malabo Energy Storage Power Station Project

- How big an inverter should I use for 60v

- Off grid solar power inverter in Guinea

- How much does a smart lithium battery energy storage cabinet cost

- 24ah cylindrical lithium battery

- Does the battery cabinet have high technical content

- Hargeisa Photovoltaic Panel Equipment Manufacturer

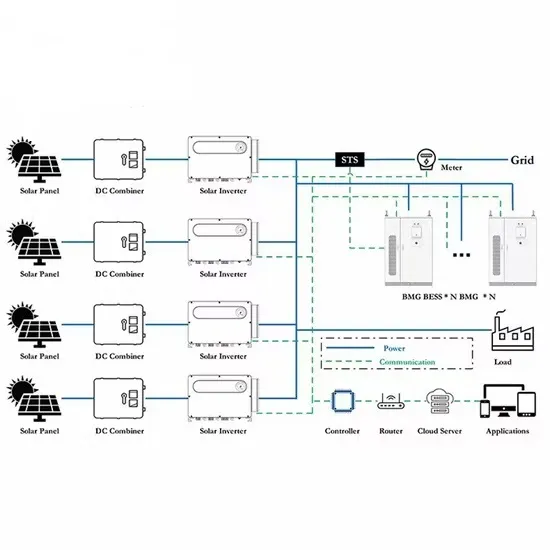

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.