Flywheel design calculation

May 11, 2024 · Explanation Calculation Example: A flywheel is a mechanical device that stores energy in the form of rotating mass. The energy stored in a flywheel is given by the formula E

Analysis of Standby Losses and Charging Cycles

Aug 27, 2020 · Aerodynamic drag and bearing friction are the main sources of standby losses in the flywheel rotor part of a flywheel energy storage system

Flywheel Energy Storage Calculator

Flywheel energy storage systems work by converting electrical energy into mechanical energy and storing it in a spinning flywheel. When the stored energy needs to be released, the

Flywheel design calculation

May 11, 2024 · A: The main challenges associated with flywheel energy storage include the high cost of manufacturing flywheels, the need for specialized materials, and the potential for safety

Flywheel Energy Storage Calculator

Oct 11, 2024 · A Flywheel Energy Storage Calculator is a sophisticated tool designed to compute the energy stored in a flywheel system. By using both kinetic energy principles and rotational

Flywheel Energy Dynamics: Calculation of Stored Energy and

Jun 22, 2024 · Popularity: ⭐⭐⭐ Flywheel Design Calculations This calculator provides the calculation of energy stored and heat generated by a flywheel. Explanation Calculation

Flywheel Design: Calculation & Considerations | StudySmarter

Flywheel design is an engineering practice that focuses on creating a rotating mechanical device to efficiently store rotational energy. Optimized parameters in flywheel design include material

Design and prototyping of a new flywheel

Sep 5, 2017 · This study presents a new ''cascaded flywheel energy storage system'' topology. The principles of the proposed structure are presented.

Mechanical Design Calculations of Flywheel

Dec 6, 2019 · A flywheel energy storage machine in which the disk rotor contains the field excitation windings appears to be a practical approach to meeting

Flywheel Energy Storage Calculator

Oct 11, 2024 · Gain insight into the pivotal formula that drives the Flywheel Energy Storage Calculator. This formula is the cornerstone of accurately determining energy storage

Energy storage flywheel inner diameter calculation formula

Control Method of High-power Flywheel Energy Storage System 2.1 Arcsine CalculationThe direct arcsine calculation method has less computation and faster response speed, and it can

Calculation of thermal power flywheel energy storage benefits

Are flywheel energy storage systems environmentally friendly? Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to

Design of energy storage system for communication

The analysis results show that the participation of idle energy storage of 5G base stations in the unified optimized dispatch of the distribution network can reduce the electricity cost of 5G base

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · According to the previous equation, the most efficient way to increase the stored energy is to speed up the flywheel. For steal rotors, the dominant shape is a solid cylinder,

Flywheel Energy Storage Calculator (Energy Only)

Definition: This calculator computes the rotational energy (E) stored in a flywheel, based on its mass, radius, shape, and angular velocity. Purpose: It is used in engineering to design and

(PDF) Sizing design and implementation of a

Jan 1, 2016 · In this paper, a flywheel energy storage system has been designed for satellite attitude control systems. Power requirements of a small

Flywheel Energy Storage Calculations | True Geometry''s Blog

Oct 5, 2024 · Calculation Example: A flywheel is a mechanical device that stores energy in the form of rotating mass. The energy stored in a flywheel is given by the formula E = 1/2 * I * ω^2,

Composite Flywheels for Energy Storage

Jun 7, 2017 · Thus, a single composite flywheel can be equivalent, in stored energy, from one to more than 100 automotive batteries. Moreover, in flywheel systems, the stored energy and

Modeling flywheel energy storage system

May 29, 2020 · Here, we focus on some of the basic properties of flywheel energy storage systems, a technology that becomes competitive due to recent

Flywheel-Based ESS Energy Storage Estimation Calculator

Mar 7, 2025 · Explanation Energy Storage Calculation Example: This calculation estimates the energy storage capacity required for a flywheel system to provide grid frequency stabilization.

AC Flywheel battery (Theory) : Energy Storage Labs :

Aug 19, 2025 · To calculate the efficiency of energy transfer between battery and flywheel and between flywheel and battery. Refer the characteristics plotted in the data set and observe the

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · This article describes the major components that make up a flywheel configured for electrical storage and why current commercially available designs of steel and composite rotor

flywheel energy storage cycle calculation formula table

Mechanical Design Calculations of Flywheel Generator This paper focuses on design calculations related to flywheel energy storage system (FESS) being developed at IIT Delhi. The flywheel

Flywheel Design and Sizing Calculation Example

Nov 16, 2014 · Fundamental Principles of Flywheel Design and Sizing Calculations. Firstly, calculate the mass moment of inertia required by the

Flywheel Energy Storage Basics

4 days ago · The high energy density and low maintenance requirements make it an attractive energy storage option for spacecraft. Conclusion: Flywheel

(PDF) Design and Analysis of Flywheel for

May 5, 2017 · The flywheel is the simplest device for mechanical battery that can charge/discharge electricity by converting it into the kinetic energy of a rotating

Flywheels

4 days ago · The kinetic energy stored in flywheels - the moment of inertia. A flywheel can be used to smooth energy fluctuations and make the energy flow intermittent operating machine

flywheel energy storage density calculation formula

Design and prototyping of a new flywheel energy storage system This study presents a new ''''cascaded flywheel energy storage system'''' topology. The principles of the proposed structure

Flywheel Design Sizing Calculation Tutorial with

Nov 23, 2014 · Flywheel design and sizing calculation tutorial for Automobile Engine and Other Application with worked out example is discussed here.

Flywheel Energy Storage Calculation | True Geometry''s Blog

Jun 22, 2024 · Popularity: ⭐⭐⭐ Flywheel Energy Storage Calculator This calculator provides the calculation of energy stored in a flywheel for mechanical engineering applications.

The key factors in the design and construction of advanced flywheel

Oct 10, 1996 · This paper develops a flywheel energy storage system from first principles and illustrates this with a design for Pirouette/sup TM/ by International Energy Syst

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · A multi-base station cooperative system composed of 5G acer stations was considered as the research object, and the outer goal was to maximize the net profit over the

Flywheel-Based ESS Energy Storage Estimation Calculator

Mar 7, 2025 · Energy Storage Calculation Example: This calculation estimates the energy storage capacity required for a flywheel system to provide grid frequency stabilization.

flywheel energy storage calculation formula

A review of flywheel energy storage systems: state of the art and A FESS consists of several key components: (1) A rotor/flywheel for storing the kinetic energy. (2) A bearing system to support

Design and prototyping of a new flywheel

Sep 5, 2017 · Electromechanical behaviour of the system is derived base on the extension of the general formulation of the electric machines. Design

Energy management strategy of Battery Energy Storage Station

Sep 1, 2023 · New energy is intermittent and random [1], and at present, the vast majority of intermittent power supplies do not show inertia to the power grid, which will increase the

Optimal configuration of 5G base station energy storage

Mar 17, 2022 · Abstract: The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize

Flywheel Design and Sizing Calculation Example

Nov 16, 2014 · Flywheel design and sizing calculation principles, formulae and practical example with step by step numerical solution is explained here which

6 FAQs about [Communication base station flywheel energy storage design calculation formula]

What is a flywheel energy storage calculator?

Explore the innovative Flywheel Energy Storage Calculator developed by Newtum. Uncover the potential of flywheel technology in energy storage and management, sparking your curiosity to learn more. A Flywheel Energy Storage Calculator is a sophisticated tool designed to compute the energy stored in a flywheel system.

How much energy is stored in a composite flywheel?

Typical energies stored in a single unit range from less than a kilowatt-hour to levels approaching 150 kilowatt-hours. Thus, a single composite flywheel can be equivalent, in stored energy, from one to more than 100 automotive batteries. Moreover, in flywheel systems, the stored energy and output power are relatively independent of each other.

How do you calculate kinetic energy stored in a flywheel?

Consider a flywheel with a certain mass and radius, spinning at a specified angular velocity. By inputting these values into the calculator, you receive the total kinetic energy stored. For instance, if a flywheel with a mass of 20 kg and a radius of 0.5 m spins at 3000 RPM, the calculator will provide the energy stored in Joules.

What are the basic principles of Flywheel design & sizing?

Fundamental Principles of Flywheel Design and Sizing Calculations Firstly, calculate the mass moment of inertia required by the flywheel to smoothing out the fluctuation/variations of kinetic energy in the system. This will be discussed in this article.

What determines the output power of a flywheel?

In a flywheel, geometry, materials, and rotational velocity set the stored energy. The design of the output circuit defines the output power, constrained, of course, by the fact that the time for which the peak output power can be drawn is limited by the stored energy.

How many batteries can a composite flywheel have?

Thus, a single composite flywheel can be equivalent, in stored energy, from one to more than 100 automotive batteries. Moreover, in flywheel systems, the stored energy and output power are relatively independent of each other. Flywheels under design or construction or testing include those shown in Table 1.

Industry Information

- Jamaica 5g communication base station flywheel energy storage construction project bidding

- Outdoor power supply 220v selection

- Battery cabinet purchase price

- Outdoor power supply charging overnight

- Photovoltaic glass energy conversion rate

- Koten safety breaker for sale in Us

- How about the major of Communication Base Station Energy Management System Design

- 5kwh battery storage in China in Ethiopia

- China Southern Power Grid Energy Storage Control Solution

- Copenhagen container lithium iron phosphate battery

- Application of photovoltaic double-glass components

- Mali new flow battery research and development company

- Mali photovoltaic glass broken glass

- Intelligent integrated communication base station inverter grid-connected equipment

- China upgrade circuit breaker in Cambodia

- Sf6 circuit breaker in hindi in Sudan

- Latest Lead-acid Batteries for Communication Base Stations in South America

- Industrial switchgear factory in Italy

- How much does BESS outdoor power supply cost in Turkmenistan

- Uninterruptible Power Supply Agents in Ireland

- Is there any base station factory in Luxembourg

- Factory price 240 amp breaker in Atlanta

- Kyiv Photovoltaic Glass Project

Commercial & Industrial Solar Storage Market Growth

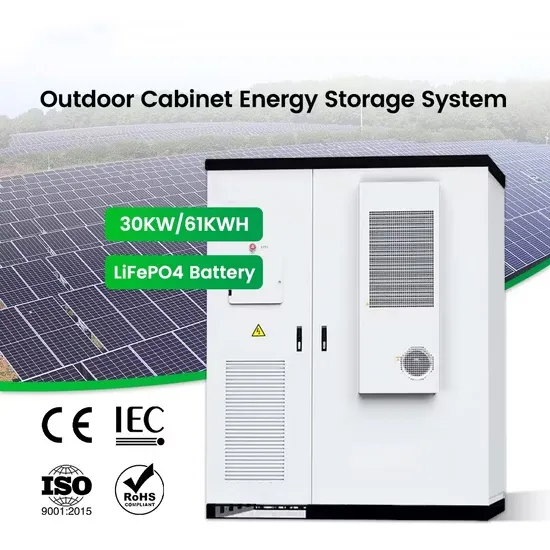

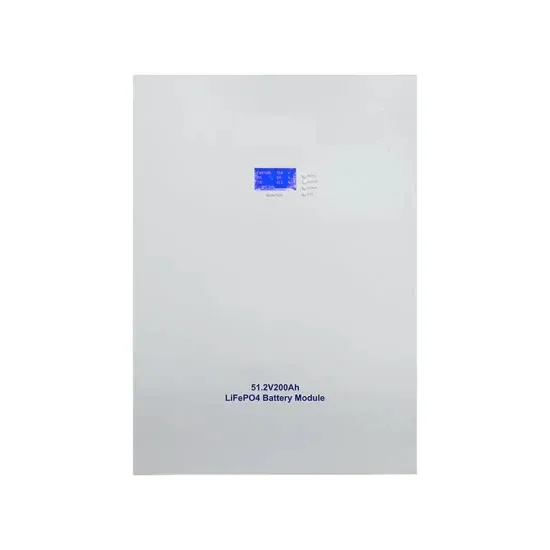

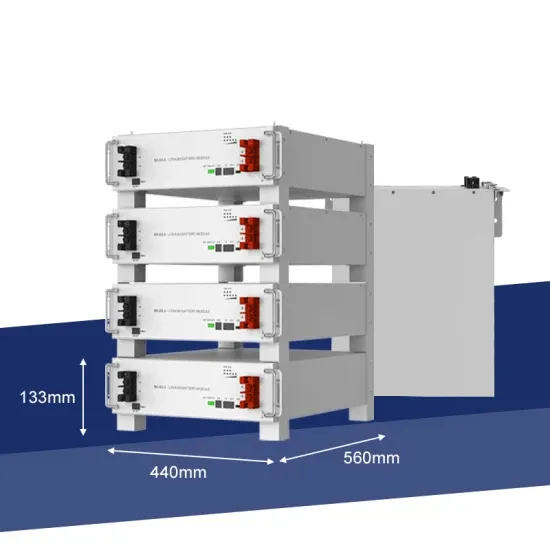

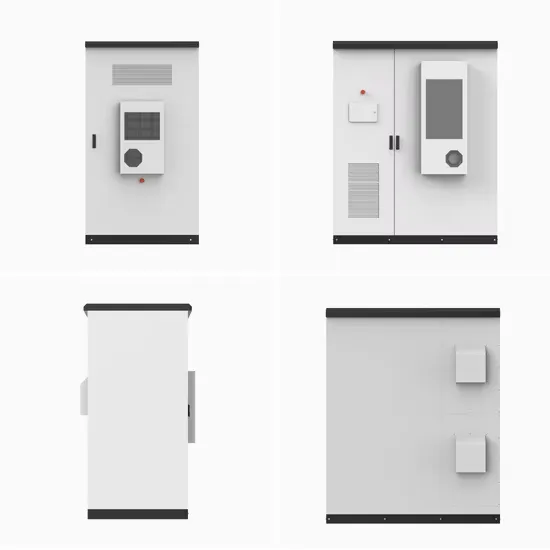

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.