What kind of energy storage is suitable for steel

Apr 16, 2024 · 1. Energy storage that is suitable for steel plants includes battery storage systems, compressed air energy storage, thermal energy storage, and

Efficiency and Energy Consumption in Steel

Mar 15, 2024 · Modern steel production uses electric arc furnaces that can recycle scrap steel, reducing energy consumption compared to traditional

Decarbonizing Iron and Steel with Hydrogen | Hitachi Energy

May 16, 2024 · In 2023, Nordic-based Ovako became the world''s first steel producer to use green hydrogen to heat steel before rolling at one of its plants in Sweden. Hitachi Energy played an

Enhancing Operational Efficiency in Steel Plants

Mar 19, 2025 · need for optimal use of equipment and resources. Key performance indicators (KPIs) for evaluating the operational efficiency of integrated steel plants include raw material

Energy-Efficient Steel Plants: Innovations Driving

Apr 28, 2022 · Future Trends in Energy-Efficient Steel Manufacturing Integrating Artificial Intelligence (AI) and machine learning in steel plants improves

Fact sheet Energy use in the steel industry

May 27, 2022 · Medium-term energy eficiency improvements in the steel industry are expected through technology transfer, or applying best-available technology to outdated steel plants

Management of Energy in a Steel Plant – IspatGuru

Jun 7, 2015 · The energy centre generates proposals for energy-efficient operation of steel plant production facilities and helps plant operators plan

Electricity explained Energy storage for electricity generation

Energy storage for electricity generation An energy storage system (ESS) for electricity generation uses electricity (or some other energy source, such as solar-thermal energy) to charge an

Global Iron and Steel Tracker

Global Iron and Steel Tracker The Global Iron and Steel Tracker (GIST) provides information on global crude iron and steel production plants, and includes

Steel Plant Energy Storage: Powering the Future of

Jul 14, 2019 · Hydrogen energy storage in steel plants is turning heads faster than a red-hot ingot. Here''s why: Hydrogen acts as both fuel and reducing agent (talk about multitasking!) It''s not

Battery Energy Storage Systems Report

Jan 18, 2025 · This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

Move over, data centers. US steel mills need lots

Nov 18, 2024 · The United States is the world''s fourth-largest steel producer, and today, most of the country''s primary steel is made using coal in scorching-hot

Sustainable Energy Management Practices in Steel Plants

Jul 4, 2025 · As steel plants are among the most energy-intensive industrial operations, they present a significant opportunity for sustainable energy management practices. By integrating

The benefits of installing energy storage in steel plants

Aug 29, 2024 · By building energy storage systems in steel plants, companies can charge during off-peak hours and discharge during peak hours, effectively adjusting peak and valley power

Do power plants need energy storage expertise

The report says many existing power plants that are being shut down can be converted to useful energy storage facilities by replacing their fossil fuel boilers with thermal storage and new

The Role of Steel in the Nuclear Sector

Nov 21, 2024 · Given our continued reliance on nuclear energy to generate electricity, the importance of steel in this industry cannot be overstated. To protect our environment and

Status, challenges, and prospects of energy efficiency

Sep 30, 2024 · While there are numerous and effective methods to enhance energy efficiency in a typical steel manufacturing system, they are relatively scattered and independent, lacking a

Structural Steel in Renewable Energy

Bioenergy and waste-to-energy plants: Bioenergy plants use structural steel for storage tanks and plant facilities. Tidal and wave energy: Structural steel''s

Steel Plant Energy Storage Power Stations: Solving Heavy

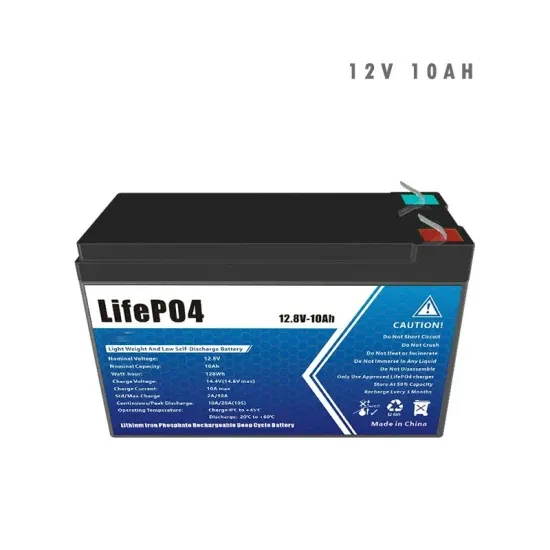

Three game-changing storage solutions are reshaping steel production: 1. Lithium-Iron Phosphate (LFP) Battery Arrays. With 15-minute response times and 95% round-trip efficiency, these

Inside a Steel Factory: Discover How Steel Is Made Step by Step

May 8, 2025 · How do modern steel plants ensure high product quality and safety? Modern steel plants integrate advanced digital monitoring, robotics, and automated quality control.

Assessing large energy storage requirements for chemical plants

Feb 1, 2025 · Energy storage requirements are assessed for around-the-clock chemical plant operation powered with variable renewable electricity.

Energy Use in US Steel Manufacturing

Oct 6, 2017 · Fruehan et al. have calculated the theoretical minimums for creating steel as well as collected data on practical minimum as and real-world energy

Steel Industry: Making Significant Energy

Apr 21, 2023 · Steel production is also responsible for 2.6 gigatons of CO2 emissions, or about 7% of man-made greenhouse gas emissions.

Utility Achieves Industry-First Hydrogen Production Using Steel

Mar 10, 2025 · With more than 3,000 hours of successful operation at a major steel plant, H2Gen has demonstrated its ability to drive a cost-effective, scalable, reliable and commercially ready

Why Do We Need Energy Storage?

Apr 23, 2025 · Thermal Energy Storage systems are particularly useful for integrating with concentrated solar power plants or industrial facilities. They

Green steel: The two-track transformation of modern

Jun 12, 2025 · Partnering beyond the equipment We don''t assume or approach green steel as a one-size-fits-all product pitch. Instead, we act as a trusted technical and consulting partner,

Efficient Energy Storage for Stable Steel

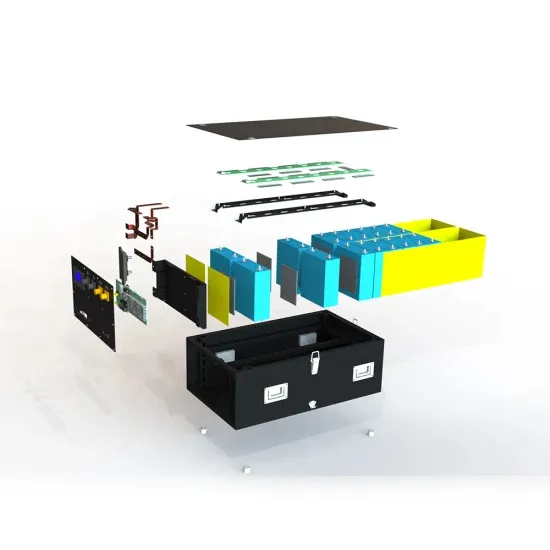

To address high energy costs during peak demand periods and support sustainable practices, Enjoypowers has installed a 36MW/72MWh large-scale

Fact sheet Carbon capture and storage (CCS)

Feb 17, 2025 · Fact sheet | Carbon Capture and Storage Carbon capture can potentially be retrofitted to conventional DRI facilities. Innovative coal-based smelt reduction plants such as

Fact sheet Energy use in the steel industry

May 27, 2022 · Energy use in the steel industry The steel industry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the

Energy and Environment Management in Iron & Steel sector

This is an initiative of Ministry of Environment & Forests/ Central Pollution Control Board (CPCB) in association with Ministry of Steel and the main/ major steel plants to reduce environment

Effective CO2 reduction for industrial steel plants

Aug 1, 2025 · Effective CO2 reduction for industrial steel plants Carbon capture and storage technologies have been shown to help steel producers reduce carbon dioxide emissions in a

The Importance of Energy Consumption and the Need for

Aug 4, 2025 · One of the world''s most energy-intensive businesses, the steel sector consumes much energy during its production operations. This research examines energy use trends in

Process intensification and comparison of electrolytic

Jan 20, 2025 · With this in mind, it can be seen that the SOE-R Design can lower the energy consumption of the steel making process compared to a NG-DRI-EAF steel plant and all of the

Types of Energy used in a Steel Plants and Energy Conservation

May 23, 2015 · Fig 1 Types of fuel energies used in steel plant Other form of energy used in steel plants After fuel energy, electricity constitute the next highest consumption of energy in the

Iron and Steel Manufacturing

4 days ago · Iron and Steel Manufacturing Steel is a vital material, valued for being lightweight yet strong. More than 1 billion tons of steel are produced

6 FAQs about [Do steel plants need energy storage equipment ]

What is a gas used for in a steel plant?

dditional fossil fuel and energy resources. They typically contribute to more than 60% of a steel plant’s energy requirements and are used either as a direct fuel substitute or for the generation of electricity.7Alternatively, gases can be us d for power generation or exported of-site. They are flar

How does steel save energy?

Fact sheetEnergy use in the steel industryThe steel ndustry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry and to minimise environmenta impacts, such as greenhouse gas emissions. Steel saves energy over its many life cycles through its 100% recyclab

Why is energy conservation important in steelmaking?

ndustry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry and to minimise environmenta impacts, such as greenhouse gas emissions. Steel saves energy over its many life cycles through its 100% recyclab lity, durability and lightweight potential.World crude steel prod

Does the steel industry need a systematic review?

Consequently, there is a critical need for a systematic review that comprehensively evaluates and improves energy efficiency in the steel industry at various levels, providing a multi-faceted and scientifically grounded approach to improving energy efficiency.

How smart is the steel industry?

Currently, the steel industry is witnessing a significant shift towards intelligent steel manufacturing and the intelligent construction of energy systems.

How does energy eficiency affect steel production?

air, water and land for 17 steel products. The LCI data is av eel.org.Energy inputs and associated costsEnergy constitutes a significant portion of the cost of steel production, from 20% to 40%.2, 3 Thus, improvements in energy eficiency result in reduced production

Industry Information

- Kiribati 5g communication base station hybrid energy bidding

- Prices of UPS uninterruptible power supply in Türkiye

- Sanaa Solar Inverter

- Germany s unique photovoltaic energy storage system

- Specifications and models of C-shaped steel fixed photovoltaic panels

- Benin Energy Storage Container Production Plant

- Budapest low-carbon photovoltaic energy storage system

- Alofi low rate lithium battery pack

- Is the Canberra cylindrical battery a lithium battery

- Accelerate the promotion of charging pile energy storage

- 72v battery energy storage charger

- Solar Light 50W Production

- Huawei photovoltaic panel expansion parts

- 5 The first power plant-side energy storage project

- Factory price 11kv switchgear in Albania

- Guatemala Industrial Energy Storage Cabinet Customization Company

- Royu circuit breaker in China in France

- Montevideo Distributed Energy Storage Cabinet Customization

- Become an energy storage battery manufacturer

- Amsterdam battery energy storage battery manufacturer

- Wholesale 10000 watt inverter in Iran

- Bahamas Twin Tower Photovoltaic Glass

- Huawei home energy storage battery

Commercial & Industrial Solar Storage Market Growth

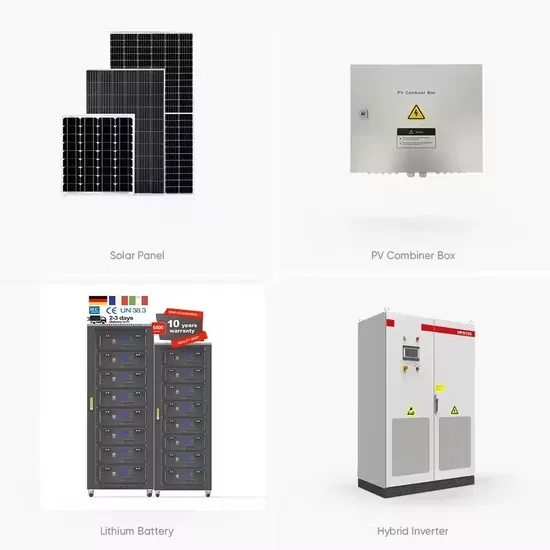

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.