PFSA NE1000 Series Perfluorosulfonic Acid Ion Exchange Resin

strip flow method. Perfluorinated ionic membrane as the separation of Yin and Yang in all kinds of cell and battery very solid electrolyte, membrane has the property of unidirectional by cation,

PFSA Membranes for fuel cells, electrolysis

Perfluorinated ion exchange membrane TPD-M10H is a single component perfluorosulfonic acid H-type ion membrane produced by tape casting. As a

Perfluorosulfonic Acid Membranes for Fuel Cells

Advances in electrochemical water conversion and understanding PEMFC degradation drive progress in hydrogen technologies.

CN115632151B

The perfluorosulfonic acid ion exchange membrane prepared by the present invention has high ion selectivity and mechanical strength, and the assembled liquid flow battery has high

Commercial perfluorosulfonic acid membranes for vanadium

Apr 1, 2018 · Abstract A series of perfluorosulfonic membranes is screened for application in vanadium redox flow batteries (VRFB): membranes of constant thickness 50 µm with different

Nafion Membranes— The Right Choice for Your Flow

Jun 18, 2024 · Solutions for the Energy Industry Powered by Chemours Science NafionTM perfluorosulfonic acid (PFSA) polymer was invented by Chemours, formerly DuPont, in the

STRUCTURE-TRANSPORT RELATIONSHIP OF PERFLUOROSULFONIC-ACID

Dec 1, 2016 · Perfluorosulfonic acid (PFSA) ionomers are widely used as an ion-conducting electrolyte in electrochemical energy devices, such as polymer-electrolyte fuel cells (PEFCs)

Commercial perfluorosulfonic acid membranes for vanadium redox flow

Apr 15, 2018 · The on-going commercialization of flow batteries is opening new business niches for component producers including ion-exchange membranes. Membrane cost still represents

Enhanced Proton-Selective Hybrid

May 6, 2025 · This study introduces a hybrid cation exchange membrane developed by in situ modification of a commercial perfluorosulfonic acid

Ion selective membrane for redox flow battery, what''s next?

Sep 1, 2023 · Herein, we discuss the developments and challenges of ion selective membranes, including ion exchange membrane and ion-conducting porous membrane, for redox flow

Tuning Polybenzimidazole-Derived Crosslinked

Jul 31, 2023 · Non-fluorinated ion exchange membranes with high proton selectivity and conductivity are sought as separators for vanadium redox flow batteries (VRFB) to substitute

Preparation and properties of amphoteric ion exchange membrane for

Sep 1, 2019 · Therefore, the most important characteristic of the membrane is high ion conductivity through the membrane to complete the redox circuit and high selectivity to prevent

New directions in perfluoroalkyl sulfonic acid–based proton-exchange

Dec 1, 2019 · Perfluoroalkyl sulfonic acid (PFSA) polymer membranes have enabled a variety of electrochemical energy storage and conversion devices such as fuel cells and flow batteries

Preparation and performance of UIO-66-NH2 enhanced proton exchange

May 21, 2024 · For proton exchange membranes (PEM) used in vanadium redox batteries (VRBs), doping metal-organic framework (MOF) materials to enhance the proton permeability

The ion and water transport properties of K+ and Na+ form

Aug 20, 2018 · Introduction Ion exchange membranes are in use in a range of situations in which they are exposed to solutions of electrolytes, sometimes quite concentrated solutions.

The characteristics and applications of Nafion

May 29, 2025 · This architecture enables efficient proton transport when hydrated, as the sulfonic groups attract and retain water, forming ionic pathways that facilitate proton conduction. Nafion

Long-term performance of hydrogen-bromine

Abstract Sulfonated poly (ether ketone) (SPEEK), perfluorosulfonic acid (PFSA), and polyvinylidene fluoride (PVDF) were wire-electrospun. Subsequently,

High Quality Ion Exchange Membrane,perfluorosulfonic acid

Apr 19, 2025 · The PFSA membranes SY11P (N-11) are non-reinforced films based on PFSA polymer, a perfluorosulfonic acid in the acid (H+) form. Our PFSA membranes perform as a

Perfluorosulfonic Acid Ion Exchange Membrane Market 2025

May 12, 2025 · The global Perfluorosulfonic Acid (PFSA) Ion Exchange Membrane market is poised for significant growth between 2025 and 2032, projecting a Compound Annual Growth

Investigations of Dongyue Series Perfluorosulfonic Acid

Jul 20, 2025 · This study systematically investigated the physicochemical properties and proton exchange membrane fuel cell (PEMFC) performance of perfluorosulfonic acid (PFSA)

Approaches to the Modification of

Modification of the intrapore space of the membrane was shown to be a way of targeting the key functional properties of the membranes. Keywords:

Unlocking ion selectivity and stability in ion exchange

Aug 1, 2025 · For optimal VFB performance, the ion exchange membrane must exhibit high proton conductivity, low vanadium ion permeability, and excellent chemical and mechanical

Commercial perfluorosulfonic acid membranes for vanadium redox flow

Feb 1, 2018 · A series of perfluorosulfonic membranes is screened for application in vanadium redox flow batteries (VRFB): membranes of constant thickness 50 µm with different ion

Characterization and process-structure-properties modeling of ion

Apr 1, 2025 · Ion exchange membranes (IEMs) play a critical role in aqueous organic redox flow batteries (AORFBs). Traditional IEMs that feature microphase‐separated microstructures are

SPEEK-co-PEK-x proton exchange membranes with

Jan 2, 2024 · Currently, the most widely used PEM is made of perfluorosulfonic acid (PFSA) materials, such as Nafion or Flemion [[5], [6], [7], [8]]. It consists of a hydrophobic perfluoro

Perfluorosulfonic Acid Polymer Membranes: Microstructure

Dec 1, 2023 · Ion-exchange membranes based on perfluorinated polymers find application in energy generation and accumulation systems, in particular, fuel cells (FC), electrolyzers, redox

Maximizing flow battery membrane performance via pseudo

Jan 1, 2025 · Perfluorosulfonic acid membranes, exemplified by DuPont''s Nafion, stand as the earliest and most extensively used ion-conducting membranes in VRFB applications [20].

Enhanced Proton-Selective Hybrid

May 6, 2025 · Proton-selective membranes present a promising solution for improving the efficiency and sustainability of acid recovery in the

Membrane contamination-driven sulfonate structuring for

May 1, 2025 · In addition to the perfluorosulfonic acid ion exchange membrane (Nafion), the non-fluorinated cation exchange membrane sPEEK, due to its excellent alkaline stability, is

Approaches to the Modification of

Abstract Polymer ion-exchange membranes are featured in a variety of modern technologies including separation, concentration and purification of gases and

Effect of the Nature of Counterion on Properties of Perfluorosulfonic

Oct 1, 2023 · Abstract The paper presents the results of a study of water uptake, ionic conductivity, and Donnan potential in systems with perfluorosulfonic acid membranes in the

Structure, Characteristics and Ion Selectivity of Perfluorosulfonic

In particular, one of the most critical components in all-vanadium redox flow batteries, proton exchange membrane fuel cells and ion membrane chlor-alkali process devices is the

6 FAQs about [Characteristics of perfluorosulfonic acid ion exchange in flow batteries]

What are the advantages and disadvantages of perfluorosulfonic acid (PFSA) membranes?

Perfluorosulfonic acid (PFSA) membranes are characterized by an optimal combination of these properties. Today, one of the most well-known practical applications of PFSA membranes is the development of fuel cells. Some disadvantages of PFSA membranes, such as low conductivity at low humidity and high temperature limit their application.

Are perfluorosulfonic membranes suitable for vanadium redox flow batteries?

A series of perfluorosulfonic membranes is screened for application in vanadium redox flow batteries (VRFB): membranes of constant thickness 50 µm with different ion-exchange capacities ranging from 0.56 to 1.15 mol eq. g −1.

What are the characteristics of perfluorosulfonic acid polymers (PFSA)?

Membrane materials based on perfluorosulfonic acid polymers (PFSA) possess a set of characteristics necessary for their practical application: high ionic conductivity and selectivity and good chemical stability, strength, and elasticity.

Do perfluorosulfonic acid ionomers have different side-chain lengths?

Perfluorosulfonic acid ionomers (PFSI) with different side-chain lengths have been investigated with respect to their morphology and electrochemical properties in vanadium flow batteries (VFB).

Why do PFSA membranes have low proton conductivities?

Further-more, many pores in the membrane become isolated from each other or their connecting channels turn out to be too narrow; therefore, the proton conductivities of PFSA membranes in this state are very low and at ~ 2 they are about 1 × 10–5 Ohm–1 cm–1 at 25°С λ (Fig. 5).

What is a PFSA membrane?

One of the most widely known polymeric ion-exchange membranes is perfluorosulfonic acid (PFSA) polymer membranes due to their unique transport properties and stability. The method of its production was developed in the late 1960s by DuPont. The product has been registered under the brand name Nafion ® .

Industry Information

- New Energy Battery Cabinet Bidding

- 350w energy storage power supply

- Three-phase full-bridge inverter series resistance

- Finnish battery storage production company

- Afghanistan s 100 billion energy storage project

- 5kw on grid inverter for sale in Iran

- Bissau Photovoltaic Glass Northwest

- Price of shingled photovoltaic panels

- Photovoltaic energy storage charging pile system

- Tirana container generator import

- 6000w solar inverter for sale in Mozambique

- Zambia super capacitor price

- Energy Storage Tracking System

- Niamey Mobile Power Station Generator

- Camping outdoor power supply 4 6 kWh

- Where is the best place to station solar photovoltaic energy storage cabinets

- Price of manufactured supercapacitors

- How many amperes does 10 watts of solar energy have

- Wholesale lv switchgear panel in Philippines

- Battery cabinet liquid cooling system voltage drop control

- DC regulated power supply and inverter

- Price of photovoltaic modules for villas in San Diego

- Sophia Photovoltaic Communication Large Battery Cabinet

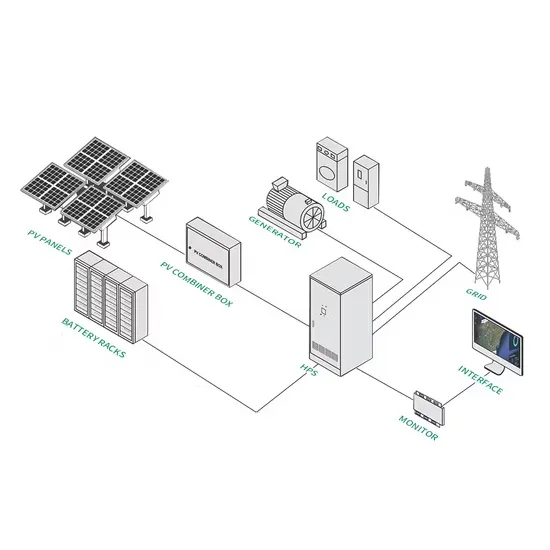

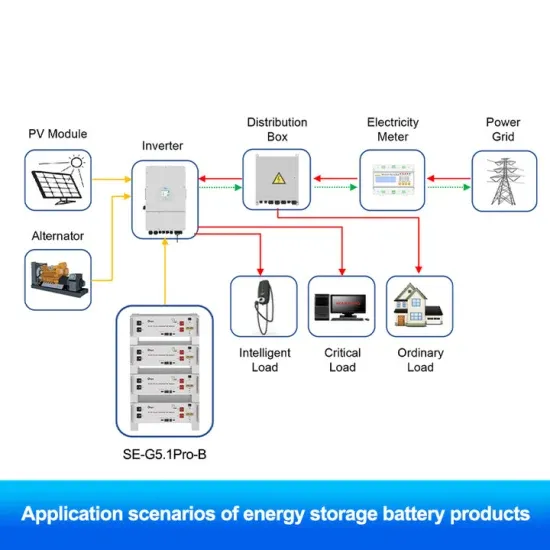

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.