6 Battery Energy Storage Systems — Lithium | UpCodes

The BESS-Li cabinets or open battery racks must be separated from other BESS-Li cabinets or open battery racks by a minimum of 3 feet (1 m) or by partitions extending from floor to

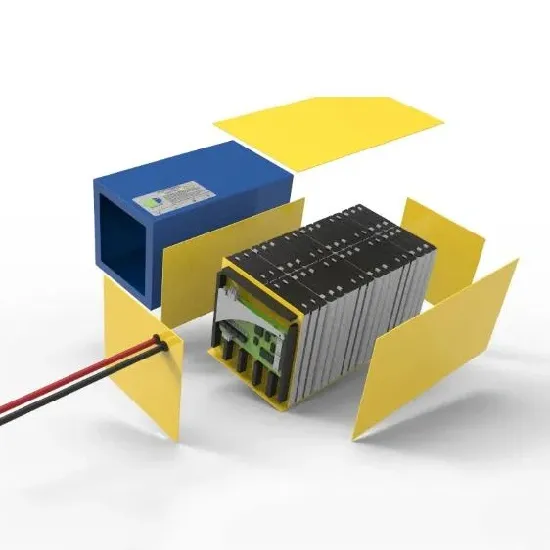

Energy storage cabinet battery specification

What is a safety standard for stationary batteries? Safety standard for stationary batteries for energy storage applications,non-chemistry specificand includes electrochemical capacitor

Technical requirements and standards for lithium battery

A lithium-ion cabinet, also known as a battery charging cabinet or battery safety cabinet, is a special fireproof storage unit designed to charge and safely store multiple batteries

Requirements for battery enclosures – Design

May 24, 2019 · Requirements for battery housings in e-vehicles are extensive: regulatory requirements; functional requirements; consideration of the installation conditions,

The latest technical specifications for lithium battery

Guide to Battery Cabinets for Lithium-Ion Batteries: 6 Essential Considerations for Safe Storage. November 28, 2024 Posted by admin; 07 Nov Lithium-ion batteries are commonly used in

Technical Specifications and Standards for Battery Thermostatic Cabinets

BATTERY CABINETS GENERALITY The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries.

Do Lithium Ion Batteries Require A Battery Room? Storage Requirements

Apr 16, 2025 · Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Battery cabinet plastic shell technical requirements

What are the design requirements of EV battery pack case? Its appearance design is mainly carried out from the aspects of material, surface anti-corrosion, insulation treatment, product

OSHA Battery Storage Requirements

Understanding OSHA battery storage regulations is key to workplace safety. Explore guidelines and tips for safe and compliant storage.

Battery Energy Storage Systems: Main Considerations for

5 days ago · This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

What are the material requirements for battery cabinets

FAQS – Battery Storage Cabinets The specific type of cabinet you need may vary depending on the battery type, as some batteries have unique storage requirements. 4. Are battery storage

What are the standard requirements for battery energy storage cabinets

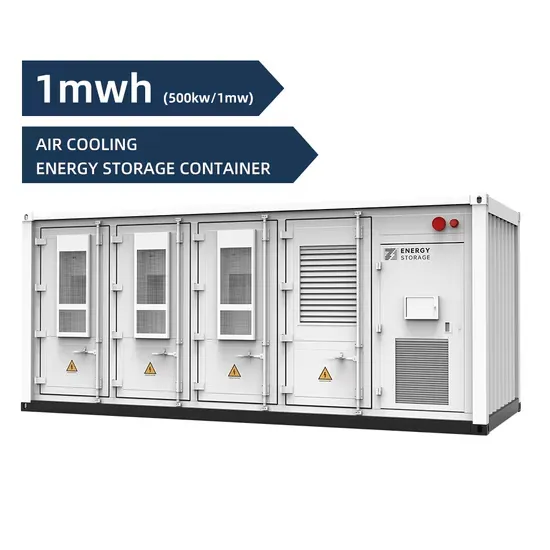

Jun 2, 2024 · Thermal management systems in battery energy storage cabinets are vital for regulating the internal temperature of the batteries. As batteries discharge and charge, they

What are the ventilation requirements for

May 22, 2024 · Ventilation for energy storage cabinets is pivotal for ensuring proper operation and longevity of installed equipment. Adequate airflow is

Technical requirements for battery cabinet cold plate

Design and optimization of cold plates require tradeoffs between conflicting requirements including thermal resistance, pressure drop and manufacturing constraints. In case of EV

Designing Industrial Battery Rooms: Fundamentals and

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards. 1. Space

Energy storage cabinet battery specification

A new edition of IEC 62619 provides the safety and performance requirements for batteries used in industrial applications. rechargeable batteries. Energy storage systems (ESS) will be

Lithium battery cabinet voltage requirements

Are Eaton lithium cabinets safe? c. Eaton has a very large installed base of lithium cabinets since 2017. It numbers in the thousands of cabinets, with no safety related failures or incidents! 7)

Technical requirements for cabinet battery compartment

This article describes best practices for designing battery rooms including practical battery stand systems and accessible cabinet enclosures .

Specification for Batteries (IEC)

Jan 18, 2021 · IOGP S-740: Specification for Batteries (IEC) This specification defines the technical requirements for the supply of the equipment.

What Are the Installation Requirements for Rack Lithium Batteries

Jul 14, 2025 · What structural specs govern rack lithium battery installations? Critical requirements include steel-composite racks supporting ≥150 kg/m² loads and multilayer stacking with

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

General Technical Specifications and Standards for

Technical Specification: sales@megarevo .cn Energy Storage System Series-Residential Energy Storage Battery Cabinet Technical Specification The Samsung SDI 128S and 136S energy

What are the waterproof requirements for outdoor battery cabinets

Waterproof requirements for outdoor battery cabinets are essential to ensure the safety, functionality, and longevity of the batteries and associated equipment in various weather

What Is a Battery Rack Cabinet and Why Is It Essential?

Jun 14, 2025 · A battery rack cabinet is a specialized enclosure designed to securely house multiple batteries in energy storage systems. It ensures thermal management, safety, and

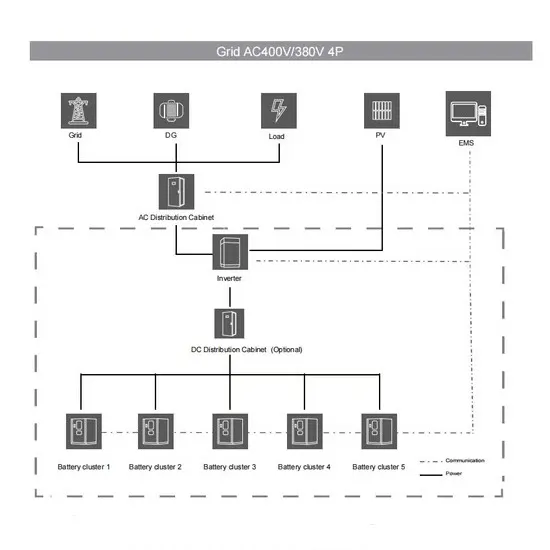

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

U.S. Codes and Standards for Battery Energy

This document provides an overview of current codes and standards (C+S) applicable to U.S. installations of utility-scale battery energy storage systems.

Energy storage cabinet quality requirements and standards

What are the customer requirements for a battery energy storage system? e battery energy storage system for emerge How should battery energy storage system specifications be based

Battery Cabinets vs. Battery Racks

Aug 27, 2018 · Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept

Lithium Ion Battery Standards Australia

Nov 2, 2023 · Explore the Australian Standards for lithium-ion battery safety and transportation, crucial for manufacturers and consumers alike.

What are the process requirements for energy storage cabinets?

Mar 8, 2024 · Energy storage cabinets require careful consideration of design specifications, materials utilized, safety measures, and regulatory compliance. 2. Appropriate sizing based on

New UL Standard Published: UL 1487, Battery Containment

2 days ago · The model fire codes have requirements for battery-powered devices focused on mitigating the potential risks of electrical shock and thermal runaway. 2024 NFPA 1 Fire Code

NFPA 70E Battery and Battery Room Requirements | NFPA

May 24, 2021 · Safety requirements for batteries and battery rooms can be found within Article 320 of NFPA 70E

6 FAQs about [What are the technical requirements for battery cabinets ]

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Do you need documentation before entering a battery room?

It is a requirement to have all the documentation in place prior to authorized personnel entering a battery room to perform a specific work task on a battery system under normal operating conditions. However, it is likely the employee will need to enter the battery room to deal with a battery system that is not operating normally.

What are the requirements for a battery layout?

The layout should accommodate: 2. Structural Requirements Floor loading capacity is critical - industrial batteries typically weigh 1500-3000 kg/m². For VLA (flooded) batteries, acid-resistant floor coatings compliant with AS/NZS 2430.3.2 are required.

What are the requirements for battery housings in E-vehicles?

Requirements for battery housings in e-vehicles are extensive: regulatory requirements; functional requirements; consideration of the installation conditions, transformation of forces and torques into the vehicle structure as well as wishes and demands of the end customer for trouble-free operation under a wide variety of climatic conditions.

Why is a battery room important?

A well-designed battery room ensures safety, compliance, and optimal battery performance while facilitating maintenance and future expansion. free hydrogen venting calculator Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency.

Industry Information

- New Delhi inverter 12v to 220v home use

- Chad lithium energy storage system prices

- Huawei power station energy storage device usage

- China-Europe Photovoltaic Inverter

- Photovoltaic flat tile roof

- Breaker distribution for sale in Yemen

- Wholesale lv switchgear panel in Burundi

- Connect the inverter to charge the battery

- Industrial switchgear factory in Uk

- Huawei Australia Sydney New Energy Storage

- Luanda energy storage container manufacturer

- How much is the price of aluminum acid energy storage battery in Zimbabwe

- Saudi Arabia hybrid energy 5G base station construction

- Solar power storage solutions in Russia

- Cheap 15kw hybrid inverter in China producer

- Yuenengda Energy Storage Outdoor Power Supply

- Acs automatic energy storage system

- How many kilowatt-hours of energy can be stored in a base station

- Photovoltaic battery energy storage costs

- Transparent solar panels photovoltaic power generation

- BESS a Singapore energy storage system manufacturer

- Energy Storage Smart Grid

- Battery cabinet base station power generation project

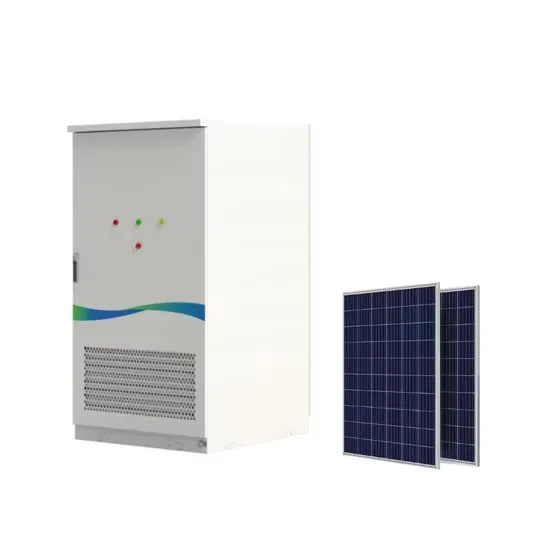

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.