Socio-Economic and Environmental Impacts of Silicon Based Photovoltaic

Jan 1, 2013 · Recycling of PV panel is currently not economically viable because waste volumes generated are too small; significant volumes of end-of-life photovoltaic panels will begin to

The principle of refining silica from photovoltaic panels

Refining the EoL silicon wafers becomes the key to close the recycling loop of the PV panels [Citation 13 -Citation 15] gure 3 compares the concentrations of typical

Mining And Refining: Pure Silicon And The

Nov 15, 2021 · Were it not for the thin sheath of water and carbon-based life covering it, our home planet would perhaps be best known as the "Silicon

PROJECT PRE-FEASIBILITY REPORT

Feb 25, 2022 · Polysilicon and Chlorosilane are used for manufacture of PV Solar panels. MG Silicon, the first ingredient in the entire Solar PV value chain is proposed to be manufactured

Residential Smart PV Solution | HUAWEI Smart

HUAWEI FusionSolar Residential Smart PV provides a one-fits-all solution from power generation, storage, to charging and power consumption. We always

Photovoltaic panel silicon wafer refining method diagram

Photovoltaic panel silicon wafer refining method diagram Can EOL silicon wafers close the recycling loop of c-Si PV panels? This study is meant to systemically examine the

Thermodynamic criteria of the end-of-life silicon

Jul 29, 2019 · Refining the EoL silicon wafers becomes the key to close the recycling loop of the PV panels [13 – 15]. compares the concentrations of

Photovoltaic panel silicon refining method

How are Solar Panels Made: An In-Depth Journey into Solar Refining into solar-grade silicon is next, which entails a two-step purification process. This gas is then distilled and reduced with

(PDF) Refining and Recycling of Silicon: A Review

PDF | On Jan 1, 2008, Arjan Ciftja and others published Refining and Recycling of Silicon: A Review | Find, read and cite all the research you need on

Silicon material refining for photovoltaic panels

The globalized supply chain for crystalline silicon (c-Si) photovoltaic (PV) panels is increasingly fragile, as the now-mundane freight crisis and other geopolitical risks threaten to...

Interviewing Resilex: recycled silicon for PV panels

May 19, 2025 · A key element is the recycling of photovoltaic panels and Si-kerf, which is the sawdust generated during silicon processing, to obtain high-purity silicon again. "The silicon

Recycling of end-of-life PV panels

Jul 16, 2024 · The process was developed in the framework of the ReSiELP (Recovery of Silicon and other materials from the End-of-Life Photovoltaic Panels) project, aiming at recovering

Photovoltaic panel refining equipment

How are silicon PV modules recycled? Recycling of silicon PV modules essentially involves three main stages : (i) manual/mechanical disassembly of decommissioned PV panels which yields

Unlocking the Power of Solar Panels: Your Ultimate Guide

May 27, 2024 · How Do Solar Panels Work? Solar panels harness the power of sunlight to generate electricity. These panels consist of cells made from semiconducting materials, most

EMBODIED ENERGY IN THE MANUFACTURE PV PANELS

Additionally, based on data produced by the Australian Government Department of Industry, Science, Energy and Resources, 1kWh of solar electricity generation

Thermodynamic criteria of the end-of-life silicon wafers refining

The collected end-of-life (EoL) silicon wafers from the discharged photovoltaic (PV) panels are easily contaminated by impurities such as doping elements and attached materials. In this

Photovoltaic panel refining equipment

Recycling of silicon PV modules essentially involves three main stages : (i) manual/mechanical disassembly of decommissioned PV panels which yields the aluminum frame, junction boxes

华为智能光伏官网-太阳能光伏发电站解决方案-光伏

点亮世界每一座"电力孤岛" 畅享安全可靠的经济绿电 专业精深,稳定可靠,更优LCOE,安全省心

Why Silicon is the Most Widely Used Material in

May 15, 2024 · Discover why silicon is used in solar panels as the key material for harvesting clean energy efficiently. Explore its vital role in solar technology.

Recycling of Solar Wafers Through Acid Leaching and Vacuum Refining

Feb 22, 2025 · Since the early 2000s, the installation of solar panels has increased rapidly, with global capacity now exceeding 1 terawatt (TW). Close to 95% of the installed solar panels

Co-recovery of Ag and Si from PV cell panels: Directional

Jan 19, 2025 · This work proposes a refining process for optimizing the separation and recovery of silver and silicon using PV glass assisted directional solidification technology, in order to

Photovoltaic panel refining method

plete deconstruction of PV panels. Aluminum, copper, tedlar, glass, ethyl vinyl acetate, silver, and silicon are all separated cleanly in the process, allowing all of the products to be utilized in

Recycling of photovoltaic silicon waste for high-performance

Aug 1, 2021 · The rapid development photovoltaic industry has generated a huge amount of waste ultra-fine silicon cutting powder. The management and value-added rec

How to extract silicon for solar panels | NenPower

Apr 30, 2024 · To extract silicon for solar panels, one must go through several intricate processes that enable the conversion of raw materials into high-purity

From Silicon to Sustainability: Unveiling the Environmental

Jan 31, 2025 · However, like any manufacturing process, solar panel production comes with its own environmental footprint. From extracting raw materials like silicon to the energy-intensive

Photovoltaic recycling: enhancing silicon wafer recovery

Apr 30, 2024 · Through investigation, this research demonstrates the feasibility and cost-effectiveness of silicon wafer recovery from damaged silicon solar panels. As photovoltaic

Thermodynamic criteria of the end-of-life silicon wafers refining

抄録 The collected end-of-life (EoL) silicon wafers from the discharged photovoltaic (PV) panels are easily contaminated by impurities such as doping elements and attached materials. In this

Photovoltaic technologies: The sun is rising

Monocrystalline silicon technologies are the most mature c-Si solar cells. Their efficiency and cost are primarily affected by the manufacturing process, which

Ranking of photovoltaic panel silicon refining manufacturers

As the photovoltaic (PV) industry continues to evolve, advancements in Ranking of photovoltaic panel silicon refining manufacturers have become critical to optimizing the utilization of

Silicon Recycling and Recovery in Photovoltaic Industry

Jun 11, 2025 · Silicon recycling and recovery methods are undergoing rapid development to recover high-purity silicon from by‐products such as kerf losses, diamond wire sawing

Photovoltaic technologies: The sun is rising

By Xu Yunlong Solar energy is becoming cost-effective thanks to recent industry advancements, in technology and commercial scaling. Both will enable the

6 FAQs about [Huawei photovoltaic panel silicon refining]

What is the value chain of the silicon photovoltaic industry?

Crystal silicon cells accounted for more than 95% of this capacity [1, 2]. Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell production, and finally photovoltaic (PV) module assembly.

Can EOL silicon wafers close the recycling loop of c-Si PV panels?

This study is meant to systemically examine the thermodynamic criteria of the metallurgical refining process of the EoL silicon wafers for closing the recycling loop of EoL c-Si PV panels.

What is the technology for silicon recovery through sintering?

The technology for silicon recovery through sintering encompasses high-temperature smelting , slag refining process , electromagnetic induction refining , and blowing refining . Major methods for physically separating and recovering silicon consist of manual sorting, electric sorting, and flotation .

Can silicon nanostructured photocatalysts be made from industrial silicon waste?

Vacuum sintering promotes the reduction of the oxide surface by Si-core. This study presents a promising route for the fabrication of composite silicon nanostructured photocatalysts from industrial silicon waste for solar hydrogen generation, demonstrating the potential for waste recovery and energy conversion.

What is photovoltaic secondary silicon containing resource (PV-SSCR)?

In the photovoltaic supply chain, a substantial amount of photovoltaic secondary silicon-containing resource (PV-SSCR), including metallurgical-grade silicon refined slag (MGSRS), silicon fume (SF), silicon cutting waste (SCW) and end-of-life silicon solar cell (ESSC) from discharged modules, can be recycled.

What are the methods of silicon recovery?

Present methods for pure Si recovery techniques include smelting and physical separation, as shown in Figure 2. The technology for silicon recovery through sintering encompasses high-temperature smelting , slag refining process , electromagnetic induction refining , and blowing refining .

Industry Information

- Bhutan photovoltaic power station inverter

- Tallinn sells brand new outdoor power supply

- Yemen Power Storage Vehicle Supplier

- Wholesale 1500 power inverter in Mombasa

- Super Farad capacitor with overcharge protection

- UPS battery cabinet with rollers

- Peru site energy storage BESS price inquiry

- Cook Islands outdoor inverter price

- Brasilia Gravity Energy Storage Project

- Low power inverter prices in Guatemala City

- Wind Solar Storage and Transmission in Honiara

- What energy storage power stations use

- Laos Solar Air Conditioning

- Xiaomi Energy Storage Power Supply Production Factory

- Dimensions of photovoltaic solar panel array

- Al hassan switchgear in China in Guyana

- Best high quality 1 2 kva inverter Seller

- Which company is better in Lima energy storage module equipment

- Three-wheel inverter price

- Cylindrical lithium battery 37v2800 mAh battery price

- Mobile solar power outdoor power supply

- Lobamba outdoor communication battery cabinet customization

- Factory price circuit breaker in Karachi

Commercial & Industrial Solar Storage Market Growth

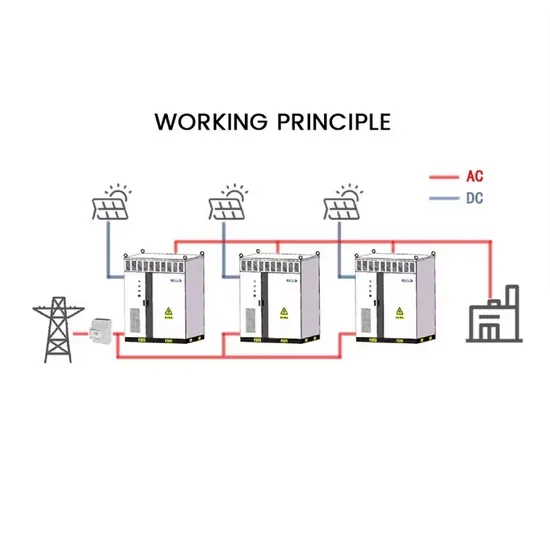

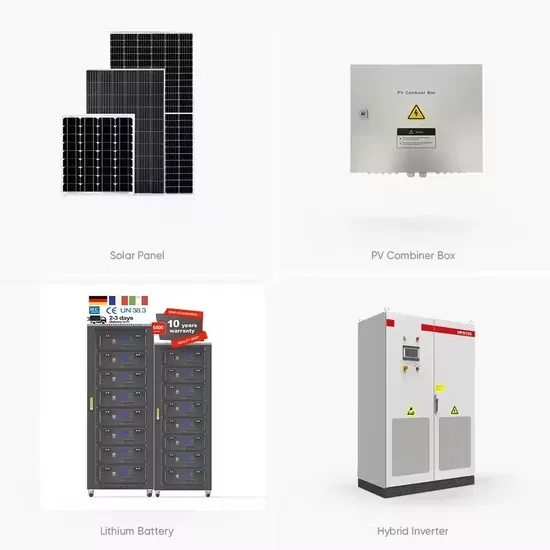

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.