Battery Cell, Module, or Pack: What''s the difference?

You''ll learn about the distinctions between battery cells, modules, and packs, as well as how to identify these essential elements for optimal battery management.

21V 4.0Ah Lithium Ion Replacement Battery Pack for

【REPLACE BATTERY PACK】| Battery Pack type: lithium ion | Voltage: 21V | Capacity: 4000mAh/4.0Ah, compatible with 21V cordless tools. Compact and Lightweight design only

Integrated Strategy for Optimized Charging and Balancing of Lithium

Oct 4, 2024 · Hence, this article proposes an optimized fast charging and balancing strategy with electrothermal regulation of LIB packs. Therefore, the power dissipation constraints of passive

Understanding the Challenges of Charging Batteries in Parallel

Aug 19, 2024 · Charging batteries in parallel requires careful attention to ensure balanced charging. Differences in capacity or charge state can lead to uneven charging rates and

How to Charge a Lithium-Ion Battery Properly: Step-by-Step

Nov 15, 2024 · Learn how to charge a lithium-ion battery safely and effectively with our guide to best practices, tips, and charging do''s and don''ts.

Can You Charge Lithium Batteries in Series?

Nov 3, 2022 · Lithium batteries are one of the most popular types of batteries on the market today. They are used in a wide variety of devices, from cell phones

Charging lithium-ion cells in series individually with multiple CC

May 11, 2020 · I''m looking to build a battery pack from lithium-ion 18650 cells, 13s16p (parallel first) to achieve around a 50V (nominal) battery pack. I realize there are probably charge

charging a lithium ion 16s battery pack

Sep 30, 2019 · 1) Separate, isolated chargers. One for each cell. Yes, expensive. 2) Charge each cell separately, sequentially, using a single (STILL ISOLATED) charger. Yes, slow. 3)

Each battery string is charged separately

Why battery chargers take a pair of batteries and not one? Good (expensive) battery chargers charge each battery individually, while the cheaper ones save on the charging circuits by

How to equalization charge Lithium ion battery pack(Cell

Dec 14, 2022 · Commonly used battery equalization charge technologies for lithium-ion battery packs include constant shunt resistor balanced charging, on-off shunt resistor equalization

How To Hook up and Install A BMS To Battery

Oct 15, 2022 · The BMS is a critical component of any lithium battery. Learning how to attach a BMS to a battery is a critical step in building lithium-ion

lithium ion

Sep 5, 2023 · 1 I''m bulding a 18650 4S pack for a speaker and I''m using a BMS capable of balancing and protecting the batteries like on the picture below.

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Standard Paralleled Cell Configuration

Feb 26, 2015 · Parallel Strings ssembling a lithium ion battery pack. However sometimes there are reasons why it may be nece ary to use multiple strings of cells. Here are a few reasons )

Why can''t lithium batteries be used in parallel at will?

Aug 2, 2025 · When connecting lithium batteries in parallel, attention should be paid to the consistency of the batteries, because parallel lithium batteries with poor consistency will fail to

Do batteries in series equalize charge

Jun 2, 2015 · Other technologies will not work. Lithium batteries even have separate ''equalising wires" connected to each cell, so the charger can adjust the current individually. Worse than

Battery Balancing: Techniques, Benefits, and How It Works

Learn how battery balancing improves performance, safety, and lifespan. Explore key techniques, benefits, and the science behind balancing battery cells effectively.

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However,

New Harbor Freight 40V Lynxx Outdoor Power

Nov 2, 2016 · The battery itself is a 40V lithium ion slide pack battery rated at 2.5ah (amp hours) and with a fuel gauge! All of Harbor Freights 18V battery

Electrical Myths, Part 3: Mixing Batteries of Different

Jul 30, 2019 · When you charge the batteries, the reverse happens–the battery with lower capacity will be charged faster, and can be overcharged. You can probably see where this is

Charging lithium-ion cells in series individually with multiple CC

May 11, 2020 · I realize there are probably charge solutions out there with the proper voltage and BMS which can be used to charge the entire pack with balancing and protection; however, my

How to Solve the Imbalance between Li-ion

Aug 1, 2022 · One Lithium Ion battery pack is composed of several cells connected in series and parallel; and in the process of our usage, we will

2 identical batteries in parallel, but unequal discharge?

May 10, 2021 · Bank = any two or more complete battery packs working in concert connected to a Common Bus. Pack = 1 completed battery assembly with BMS, Fuse - if used independently

Charging parallel battery packs

Mar 16, 2018 · Probably a good idea to keep them isolated using a Schottky or ideal diode. I use two lithium packs, both with BMS, through a Schottkey on one trike (originally from ebikes.ca),

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by connecting two or more batteries together to support a single

Ultimate Guide to Charging a LiFePO4 Battery –

Apr 2, 2025 · Charging a LiFePO4 battery correctly is key to longevity. Learn how to use a LiFePO4 battery charger, charge in parallel or series, and avoid

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · Leveraging the derived battery pack model, we introduce a refined online fast charging framework that mitigates lithium deposition. Fig. 3 outlines the architecture and

State of Charge Imbalance Classification of Lithium-ion

Oct 2, 2022 · variation, strings may have im-balanced state of charge levels, reducing pack capacity and exacerbating degradation. While much research has been devoted to individual

batteries

Oct 27, 2023 · Can I connect a Lithium ion battery battery pack with a Lead acid battery bank; in series. I will charge both separately cells strings separately (not to mix the chemistries) before

Li-Ion BMS

Given a number of cells in a battery pack (such as 100 cells), they can be arranged as sets of cells directly in parallel, which are then connected in series (such as a 2P50S battery), or as

How many strings are 48V20AH lithium battery

Mar 3, 2021 · Lithium battery pack 48V20AH generally single lithium battery is 3.5V, so 48V lithium battery pack needs 48/3.5=13.7, just take 14 in series. If

How to equalization charge Lithium ion battery

Dec 14, 2022 · When the lithium-ion battery pack is produced and stored for a long time, due to the difference in static power consumption of each circuit of

A new active cell equalizer for series connected Lithium-ion battery

Jul 1, 2025 · Consequently, a BMS is necessary for efficient cell balancing and monitoring. Without cell balancing, the available capacity of a Li-ion battery pack is reduced due to

How to make a lithium battery pack discharge a single string

Can a lithium ion battery pack have multiple strings? Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the

What Are Battery Cells, Battery Modules, And

Feb 23, 2024 · Here we''ll talk about the differences between battery cells, modules, and packs, and learn how to tell these key components for effective

Lithium battery string charging

Whenever possible,using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However,sometimes it may be

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Will Batteries Balance in Parallel? (What Does a

Nov 2, 2023 · We will be discussing how to properly balance lithium batteries in parallel so that each battery gets an equal amount of charge and discharge.

6 FAQs about [Lithium battery pack to charge a string separately]

Can a lithium ion battery pack have multiple strings?

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

What is a lithium ion battery pack?

The lithium-ion battery pack is composed of multiple single lithium-ion batteries connected in series. Due to the differences in the cells, when the terminal voltage rises inconsistently when charging in series, some cells will be overcharged and some cells will be undercharged.

How many strings should a lithium battery have?

Therefore, the lithium battery must also be about 58v, so it must be 14 strings to 58.8v, 14 times 4.2, and the iron-lithium full charge is about 3.4v, it must be four strings of 12v, 48v must be 16 strings, and so on, 60v There must be 20 strings in parallel with the same model and the same capacity.

How to shunt lithium ion batteries?

When a group of lithium-ion batteries is charged in series, each battery should be charged in a balanced manner, otherwise, the performance and life of the whole group of batteries will be affected during use. 1. Add a parallel equalization circuit to every single battery of the lithium-ion battery pack to achieve the purpose of shunting.

How many lithium batteries can be connected in series?

Lithium battery pack 48V20AH generally single lithium battery is 3.5V, so 48V lithium battery pack needs 48/3.5=13.7, just take 14 in series. If the manufacturer has provided a set of 12V lithium batteries, then 4 can be connected in series. As long as the output voltage is 48V, the current is 2A or 4A.

How many cells are in a lithium-ion battery pack?

The method undergoes a real-world electric vehicle testing with 276 cells. The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous cells in parallel or series within the packs.

Industry Information

- Foldable photovoltaic container manufacturers

- What are the functions of wind-solar complementary equipment in communication base stations

- Photovoltaic glass room supplier

- Low volume flow battery

- Photovoltaic panel series voltage and inverter

- Italian photovoltaic energy storage 15kw inverter

- Kinshasa 5g base station energy storage capacity

- Nigeria Energy Storage Battery Series Company

- Power circuit breaker factory in France

- How much is the price of Dili small energy storage cabinet factory

- What is the voltage of the electricity generated by photovoltaic panels

- How many liquid-cooled energy storage battery cabinets are there in Malaysia

- Communication base station wind power equipment installation process

- Kosovo Solar Outdoor Energy Storage Power Supply

- Smart DC Uninterruptible Power Supply Manufacturer

- Inverter sine wave and pure sine wave

- Installation of solar photovoltaic panels in Nigeria

- Riyadh UPS power supply uninterruptible power supply customization

- Huawei New Energy Energy Storage Aluminum Alloy

- Pyongyang Photovoltaic Cell Module Factory

- What are the container mobile photovoltaic power stations

- 23s lithium battery pack

- Fixed solar tiles

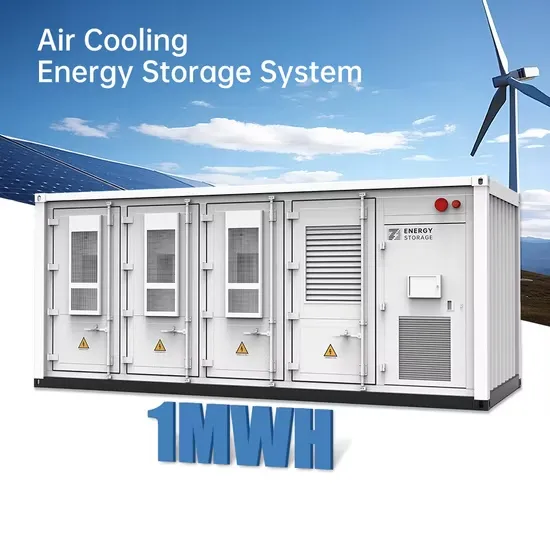

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.