Glass-Glass PV Modules

4 days ago · Glass-Glass module designs are an old technology that utilises a glass layer on the back of modules in place of traditional polymer backsheets.

Thin-Film Solar Panels (2025 Guide)

May 4, 2022 · In this EcoWatch guide on thin-film solar panels, you''ll learn: What are thin-film solar panels used for? What are the various types of thin-film

What is the impact of different thicknesses of Photovoltaic

The thickness of the glass directly affects its light transmittance. Specifically, too thick backplane glass may reduce the light transmittance of the module, causing more sunlight to be reflected

Photovoltaic Glass Treatments: Clarifying Terminologies and

However, thin glass (≤ 2 mm) cools uniformly, preventing sufficient internal stress formation for complete tempering. As a result, the tempering process fails, and the glass remains merely

Tempered Glass Thickness: All You Need To Know

Dec 27, 2024 · In summary, thin tempered glass is adequate for lighter-duty applications and offers good impact resistance for its thickness. However,

Window-Integrated PV Glass: The Future of Solar

Feb 19, 2025 · Photovoltaic (PV) glass stands at the forefront of sustainable building technology, revolutionizing how we harness solar energy in modern

Thin-film Solar Overview | Cost, types, application, efficiency

Aug 25, 2019 · These are used in developing integrated photovoltaics and as semi-transparent, photovoltaic material that is possible to laminate and use in windows. Rigid thin-film cells have

Ultra-thin Rolled Photovoltaic Glass – New Way

Jun 16, 2024 · According to the China Photovoltaic Industry Association, the penetration rate of double-glass modules is expected to reach 60% by 2025,

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Solar Glass & Mirrors Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the

What is the Difference Between Solar Photovoltaic Glass and Float Glass?

May 30, 2024 · Photovoltaic (PV) glass, used in solar panels, features special coatings for efficiency and durability, while float glass, used in construction and automotive industries, is

Crystalline vs. Thin-Film Solar Panels

Oct 24, 2023 · Compare crystalline and thin-film solar panels. Discover the similarities and differences in efficiency, cost, technology, and more.

Solar Panel Thickness: What You Need to Know

Apr 18, 2025 · Learn how solar panel thickness impacts performance, durability, and cost. This article offers insights to help you make the best purchase decision.

Types of Solar Panels: Monocrystalline vs

Jan 30, 2024 · Conclusion: Understanding the differences between monocrystalline, polycrystalline, and thin-film solar panels is crucial for making

Explained: Breaking Down the Solar Panel Triad –

Apr 25, 2025 · As solar energy adoption accelerates globally, understanding the differences between solar panel technologies is crucial for making informed decisions. The three primary

How thick is the photovoltaic panel glass

When selecting PV glass for solar panels, several key specifications need to be considered to ensure optimal performance and compatibility with project requirements.

What is the Difference Between Photovoltaic Cell and Solar Cell

Or using glass ≤0.3mm thick, making it 40% lighter than traditional materials. But these new technologies bring new problems – thin glass must pass mechanical load tests above 5400

What is the Difference Between Solar Photovoltaic Glass and Float Glass

Apr 15, 2023 · Photovoltaic glass is a special type of glass that converts sunlight into electricity by encapsulating solar cell modules in layers of glass. Usually low-iron tempered glass or double

What is thin-film PV? | PVthin

A thin-film solar cell is a solar cell that is made by depositing one or more ultra-thin layers (much thinner than a human hair), or thin-film of photovoltaic

8 Different Glass Types: Understanding the

5 days ago · Get to know the different types of glass and their applications. From tempered to laminated to float glass, information all you need to know about

Crystalline and Thin Film Solar Panels | The

The Difference Between Crystalline and Thin Film Solar Panels Explained With economic, inflation and environmental concerns worldwide, many consumers

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · What are the Differences Between Thin-Film Solar Panels and Other Types of Solar Panels? The main difference between thin-film solar

What is the difference between thin

Aug 13, 2025 · As a Solar PV Glass supplier, I understand that choosing between thin - film and crystalline solar PV glass depends on a variety of factors,

Solar glass: Through thick and thin

Feb 1, 2024 · Thin solar, and we''re talking as thin as human hair, is exactly as it sounds and will have huge ramifications on the way we gather energy from the

Thick Glass vs. Thin Glass

What is the difference between double glazed and PV glass? increases weight and potentially reduces light transmission. For example, a typical double-glazed configuratio might have a

Thick vs. Thin: What''s the Difference?

Nov 30, 2023 · Thick refers to something with considerable or substantial depth or density, while thin implies something with little depth, density, or substance.

How Glass Thickness And Composition Affect

Jul 19, 2024 · Both the thickness and composition of the glass in solar panels are crucial factors affecting their efficiency. Thicker glass offers better durability

What is solar glass?

Oct 18, 2016 · What makes solar glass different from traditional panels? BIPV - building-integrated photovoltaics - are solar panels designed to replace

Frequently Asked Questions • Photovoltaic

Our photovoltaic laminated toughened glass uses the CdTe thin film technology. The CdTe technology uses cadmium telluride in a thin semiconductor layer to

Solar glass: Through thick and thin

Feb 1, 2024 · While thin-film PV uses semiconductors like copper indium gallium (di) selenide (referred to as ''CIGS''), it''s difficult to get our minds away from

Solar Photovoltaic Glass: Classification and Applications

Jun 26, 2024 · Depending on their properties and manufacturing methods, photovoltaic glass can be categorized into three main types: cover plates for flat-panel solar cells, usually made of

What is the difference between thin

Aug 13, 2025 · Two prominent types of solar PV glass that often come under scrutiny are thin - film and crystalline solar PV glass. Understanding their

6 FAQs about [What is the difference between thick and thin photovoltaic glass]

Why do photovoltaic panels need to be thick?

The primary function of the glass is to allow sunlight to pass through and reach the photovoltaic cells. If the glass is too thick, it can reduce the amount of light that penetrates the panel, thereby decreasing the amount of energy the cells can generate. The optimal thickness balances protection with minimal light obstruction.

Why do solar panels need a thicker glass?

Firstly, the thickness of the glass used in solar panels can impact their efficiency. The thicker glass might offer better durability and protection against environmental elements like hail, dust, and debris. However, there is a trade-off. The primary function of the glass is to allow sunlight to pass through and reach the photovoltaic cells.

What happens if a solar panel is too thick?

If the glass is too thick, it can reduce the amount of light that penetrates the panel, thereby decreasing the amount of energy the cells can generate. The optimal thickness balances protection with minimal light obstruction. The composition of the glass also affects solar panel efficiency.

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

How does glass affect solar panel efficiency?

The glass covering a solar panel plays a significant role in protecting the cells while influencing how effectively they convert sunlight into energy. Understanding how glass thickness and composition affect solar panel efficiency is essential for optimizing their performance.

Is thick glass better than thin?

Each glass type has its own unique purposes and benefits, so there are several considerations when choosing optimal thickness levels. While thick glass is stronger than thin glass, boasts more pronounced edges, and is less likely to bow or warp under stress—there’s still a trade-off.

Industry Information

- EMS Standards for Caracas Base Station Room

- Local mechanical equipment inverter price

- Photosynthetic solar water pump

- Outdoor power supply can be connected externally

- Companion 40ah power station in Uruguay

- Usb c power station for sale in Johannesburg

- 120V Inverter Price

- Wireless Communication Simulcast Base Station

- 600 type photovoltaic panel size

- Base station communication equipment is built in the house

- Africa polycrystalline photovoltaic panel prices

- 12v simplest inverter

- Chile container energy storage fire fighting system

- Astana grid-side energy storage cabinet supplier

- Installation requirements for grid-connected lightning protection boxes for communication base station inverters

- Is sodium pyroantimonate used in photovoltaic glass

- Cheap earth leakage breaker factory for sale

- Hot sale earth leakage breaker factory Buyer

- High-power battery cabinet communication base station

- 200w solar water pump

- Reykjavik lithium battery inverter

- What are the functions of small generator power stations

- 100kw off-grid inverter price in Central Africa

Commercial & Industrial Solar Storage Market Growth

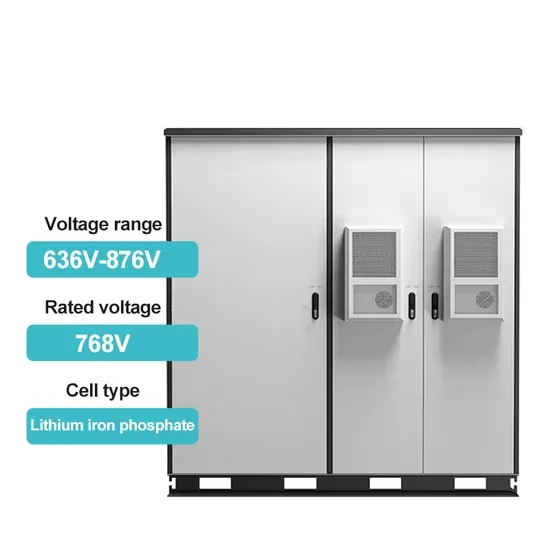

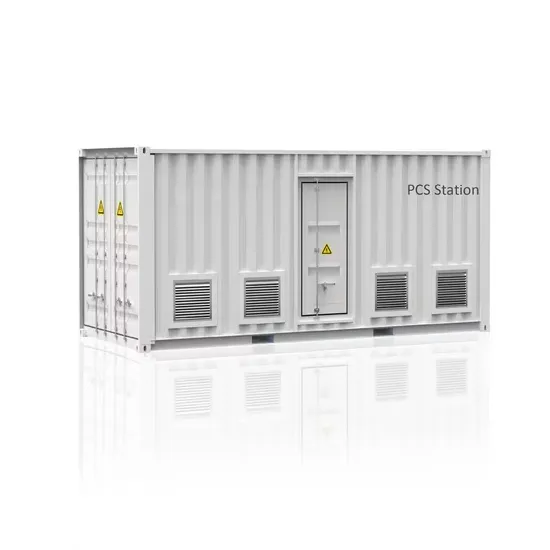

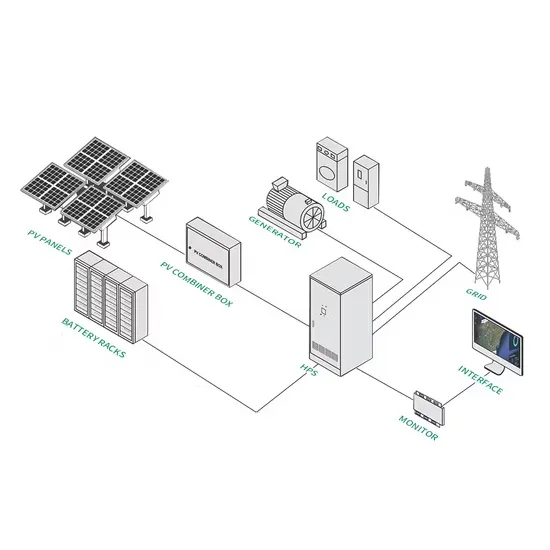

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.