Lithium Cell Manufacturing Line

Dec 12, 2024 · Lithium Cell Manufacturing Line: Key to Efficient and Scalable Battery Production A lithium cell manufacturing line is a specialized production facility designed to manufacture

Ultimate Guide to Equipment for Lithium Battery Assembly

Jan 23, 2025 · Here are some common types: Electrode Coating Machines: Used to apply active materials onto metal foils. Slitting Machines: Cut coated electrodes into precise widths.

99.9% Pure Nickel Strip for the Spot Welding of

This pure nickel strip is used for the spot welding of battery pack assembly production, the ease of processing and low resistance of this material make it

How to Assemble an Electric Bike Battery Pack – BATTERYINT

Jul 10, 2025 · Is it easy to DIY an e-bike battery pack? DIY battery packs require a certain technical threshold. Battery cell matching and capacity division are extremely important. It is

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Cell Assembly and Spot Welding. Fixture Placement: Arrange cells precisely in designated fixtures. Spot Welding: Use automatic battery welding

How to Build a Lithium Battery: Step-by-Step for Beginners

Feb 22, 2024 · How to build a lithium battery pack? 1. Prepare materials and tools. The following materials and tools are required to assemble the lithium battery pack. a. Lithium battery cell:

How to Build a Lithium Battery: Step-by-Step for

Feb 22, 2024 · 1. Prepare materials and tools The following materials and tools are required to assemble the lithium battery pack. a. Lithium battery cell:

9 Steps to Know How a Battery Pack Is Made

This step also involves ensuring that the battery pack is designed to fit within the specific dimensions required for its application, whether it''s for an electric

Lithium Batteries: Safe Assembly & Usage Best Practices

Discover how to safely assemble and manage lithium batteries. Learn key precautions, parameters, and why using reliable battery manufacturing equipment is critical for performance.

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Assembly And Testing Machine – arbaccessories

LITHIUM-ION BATTERY ASSEMBLY AND TESTING MACHINE ARB Accessories, being the leading supplier of battery production equipment,

Material and equipment required for making lithium

Lithium battery manufacturing equipment encompasses a wide range of specialized machinery designed to process and assemble various components,including electrode

The Essential Guide to Equipment for Lithium Battery Assembly

Feb 11, 2025 · As the demand for these batteries increases, so does the need for the precise and effective assembly of lithium batteries. This guide will explore the essential equipment needed

Lithium Battery Pack Assembly: A

May 6, 2024 · As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the

How Are Lithium Battery Packs Assembled?

Aug 18, 2025 · How Are Lithium Battery Packs Assembled? Lithium battery packs are essential components in various applications, from electric vehicles to renewable energy storage

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Jun 15, 2025 · Assembling your own custom battery pack allows you to tailor a power solution to your specific needs, whether for an electric vehicle, solar storage system, robotics project or

Introduce battery assembly production pack line equipment

Jun 6, 2025 · New energy lithium battery assembly production pack line equipment is a set of equipment systems specifically used to assemble lithium batteries. It includes a series of

Lithium Battery Assembly and Usage Best

Feb 20, 2024 · The following materials and tools are required to assemble lithium batteries: Lithium battery monomer: choose the appropriate lithium battery

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The Three Main Stages of Battery Cell Production The production process of a lithium-ion battery cell consists of three critical stages: electrode

How to Assemble a Lithium-Ion Battery Pack

Oct 7, 2024 · Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

I will share the list of equipment required for the cylindrical

📋I will share the list of equipment required for the cylindrical lithium battery pack line for many friends who are engaged in energy storage and finished electronic digital products plan to

DIY Professional 18650 Battery Pack

DIY Professional 18650 Battery Pack: The world is shifting away from fossil fuels and will one day become fully electric. In the present world, Lithium-ion is the

What materials are needed for lithium battery assembly

What do we have for lithium-ion battery pack assembly? Barley Paper,PVC, High-temperature Resistant Adhesive Tape et . We have complete solution for lithium What are lithium ion

How to assemble lithium battery pack 48V53a

Once you have the required number of cells, it''s time to assemble your 48v battery pack. Follow these steps for a successful assembly: Gather the necessary tools and safety equipment,

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as voltage, capacity, and size constraints.

How to Build a Lithium Ion Battery Pack? A Step

Apr 9, 2025 · Below is a list of materials and tools that need to be prepared in how to build a lithium ion battery pack that is efficient and safe. Select the

Innovating battery assembly

Aug 13, 2025 · EV batteries have become an integral part of the vehicle structure, making lithium-ion cell assembly and their integrity a safety-critical issue. One major diferentiating feature of

How to Dissemble Lithium Battery Packs and

Nov 3, 2022 · Learning how to dissemble lithium-ion battery packs is a great way to score some lithium batteries and cells for cheap.

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · The lithium battery module PACK production line is a complex system project involving multiple links and aspects of management and

Battery Equipment Solutions for Cell

5 days ago · Commercial manufacturing and R&D Battery Equipment solutions for lithium-ion battery, supercapacitor and energy storage system manufacturers.

6 FAQs about [Equipment required to assemble lithium battery pack]

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

How does a lithium battery pack work?

Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment. Quality Control: Every step, from mixing to testing, demands extreme precision. Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

What are the three stages of lithium-ion battery assembly?

The lithium-ion battery assembly process can be categorized into three key stages: 1. Front-End: Electrode Manufacturing This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell-making machine workflow.

How should lithium batteries be protected?

Lithium batteries should be protected from severe vibration and external impact during assembly and use to avoid damaging the battery structure and performance. In applications such as mobile equipment and electric vehicles, suitable securing and cushioning measures should be taken. 5. Pay attention to storage conditions

How to build a lithium battery?

Part 4. Conclusion Building a lithium battery involves several key steps. First, gather the necessary materials, including lithium cells, a battery management system, connectors, and protective casing. Begin by designing the battery layout, ensuring proper spacing and alignment of cells.

Why is quality control important in a lithium battery pack assembly?

Consequently, this intricate step paves the way for efficient power transfer and optimal pack performance. Quality control is a cornerstone of the lithium battery pack assembly process.

Industry Information

- Indonesia PV combiner box price

- 6v lithium battery pack 4500

- Huawei inverter and energy storage

- Hybrid solar inverter factory in Guinea

- Non-silicon flexible photovoltaic panels

- Pulse inverter 12v24v to 220v

- Cuba Industrial Energy Storage Project

- What is the uninterruptible power supply UPS function

- Smart hybrid inverter factory in Honduras

- Economical and durable life of uninterruptible power supply

- East Africa Energy Storage Photovoltaic Project Installation

- Lisbon 5g base station outdoor cabinet

- Nauru Energy Storage Power Direct Sales

- What photovoltaic panels are used on sloping roofs

- Rooftop solar rainproof photovoltaic panels

- Sucre photovoltaic panel installation manufacturer

- The role of combiner box in photovoltaic power generation

- Retractable solar power generation system

- San Diego Solar Power Generation System

- High quality power switchgear in Guinea

- St Lucia Off-Grid Inverter Installation

- Outdoor 24v solar powered water pump

- How about solar energy storage inverter for communication base station Communication power supply

Commercial & Industrial Solar Storage Market Growth

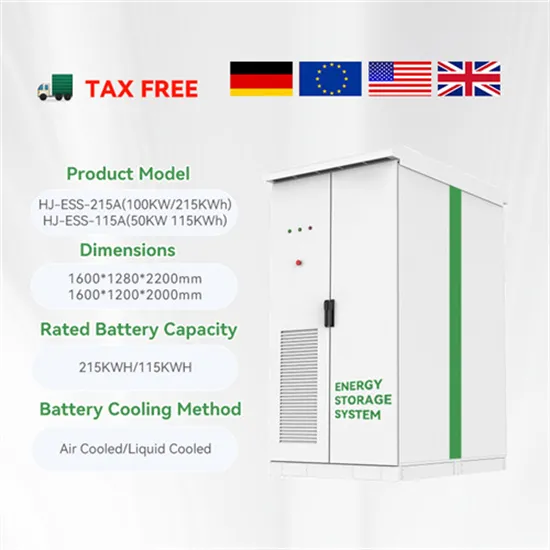

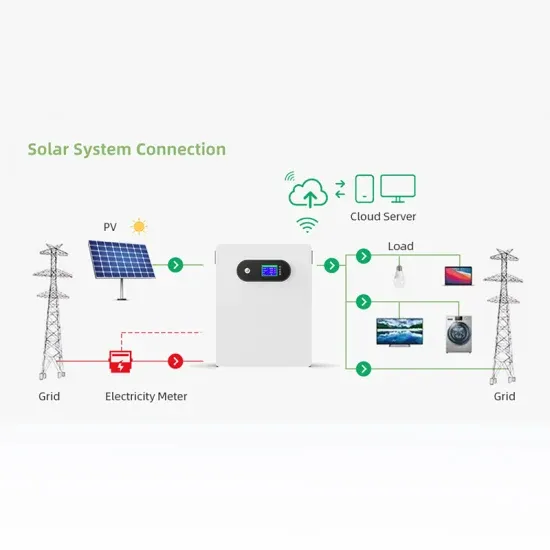

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.