Solveno Technologies | Liquid Air Energy Storage (LAES)

Aug 14, 2025 · LAES (Liquid Air Energy Storage) is a technology that stores energy by cooling air to create liquid, which can be later used to produce electricity.

Liquid Cooling Energy Storage System Design: The Future of

May 18, 2025 · Now imagine scaling that cooling magic to power entire cities. That''s exactly what liquid cooling energy storage system design achieves in modern power grids. As renewable

Energy Storage Liquid Cooling Principle: The Future of

Enter energy storage liquid cooling principle—the unsung hero keeping your renewable energy projects cool under pressure. As the global energy storage market races toward 1,000 GW

What is the liquid for energy storage liquid

Mar 15, 2024 · 1. Energy storage liquid cooling utilizes specialized liquids to dissipate heat during energy storage processes, ensuring optimal

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

What is energy storage liquid cooling liquid

Jan 29, 2024 · Energy storage liquid cooling liquid refers to a sophisticated medium utilized in various energy storage systems, primarily in thermal

Liquid Cooling

1.1.2 Liquid cooling Due to its high specific heat capacity and thermal conductivity, liquid cooling is a much more efficient way to remove heat than air-cooling. This technique involves either

What is a liquid cooling energy storage system and its

Oct 28, 2024 · A liquid cooling energy storage system is a system that uses liquid as a cooling medium to remove heat generated by the equipment through circulation. In an energy storage

Cooling Storage

Heat storage refers to the process of storing thermal energy for later use, which can involve mechanisms such as sensible heat storage, latent heat storage, and chemical reactions. It

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · To achieve superior energy efficiency and temperature uniformity in cooling system for energy storage batteries, this paper proposes a novel indirect liquid-cooling system based

Comprehensive Review of Liquid Air Energy

Jul 31, 2023 · In recent years, liquid air energy storage (LAES) has gained prominence as an alternative to existing large-scale electrical energy storage

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Thermal Energy Storage

Thermal energy storage (TES) is a technology that reserves thermal energy by heating or cooling a storage medium and then uses the stored energy later for electricity generation using a heat

Principles of liquid cooling pipeline design

3 days ago · Energy storage liquid cooling systems generally consist of a battery pack liquid cooling system and an external liquid cooling system. The core

What Is ESS Liquid Cooling?

2 days ago · Discover the advantages of ESS liquid cooling in energy storage systems. Learn how liquid cooling enhances thermal management, improves efficiency, and extends the lifespan of

Thermal Management Design for Prefabricated Cabined Energy Storage

Jul 31, 2022 · With the energy density increase of energy storage systems (ESSs), air cooling, as a traditional cooling method, limps along due to low efficiency in heat dissi

Hydrogen liquefaction and storage: Recent progress and

Apr 1, 2023 · Among these, liquid hydrogen, due to its high energy density, ambient storage pressure, high hydrogen purity (no contamination risks), and mature technology (stationary

What is full liquid cooling energy storage

Apr 17, 2024 · 1. Full liquid cooling energy storage is an innovative technology designed to enhance energy storage and management through the use of

Why Can Liquid Cooled Energy Storage System Become an

Aug 28, 2023 · Energy storage liquid cooling technology is a cooling technology for battery energy storage systems that uses liquid as a medium. Compared with traditional air cooling methods,

Liquid Cooling System Design, Calculation, and

Aug 19, 2025 · Explore the application of liquid cooling in energy storage systems, focusing on LiFePO4 batteries, custom heat sink design, thermal

Review on operation control of cold thermal energy storage in cooling

Jun 1, 2025 · This review provides an overview and recent advances of the cold thermal energy storage (CTES) in refrigeration cooling systems and discusses the operation control for

Liquid Air Energy Storage: Efficiency & Costs

Mar 29, 2023 · Liquid Air Energy Storage (LAES) applies electricity to cool air until it liquefies, then stores the liquid air in a tank.

An Overview of Hydrogen Storage Technologies

Aug 11, 2024 · ABSTRACT How to store hydrogen efficiently, economically and safely is one of the challenges to be overcome to make hydrogen an economic source of energy. This paper

Air Cooling vs. Liquid Cooling: Why Liquid

Feb 8, 2025 · With its superior thermal performance, enhanced energy efficiency, and improved battery longevity, liquid cooling is rapidly becoming the

How Is The Design Of The Energy Storage Liquid

Mar 17, 2025 · The liquid cooled container system reduces the design of internal air ducts, adopts an external maintenance system, eliminates the need for

What is the concept of liquid cooling energy

Mar 18, 2024 · Liquid cooling energy storage harnesses the properties of liquids to manage and store thermal energy, offering an innovative approach to

Liquid cooling of data centers: A necessity facing challenges

Jun 15, 2024 · This article is intended to serve as a comprehensive roadmap to understanding this shift. It covers four major liquid cooling techniques: indirect water cooling with rear door heat

Liquid cooling vs air cooling

Aug 24, 2023 · Temperature has an impact on the performance of the electrochemical energy storage system, such as capacity, safety, and life, so

What is the concept of liquid cooling energy

Mar 18, 2024 · The implementation of liquid cooling energy storage mechanisms can be observed across numerous sectors. For instance, data centers utilize

Liquid air energy storage – A critical review

Feb 1, 2025 · For large-scale electricity storage, pumped hydro energy storage (PHS) is the most developed technology with a high round-trip efficiency of 65–80 %. Nevertheless, PHS, along

Liquid Cooling in Energy Storage | EB BLOG

Oct 22, 2024 · Energy Storage Systems: Liquid cooling prevents batteries and supercapacitors from overheating, providing continuous operation.

What is the liquid cooling energy storage

May 18, 2024 · 1. Liquid cooling energy storage strategies involve the use of liquid-based solutions to store and manage energy efficiently, utilizing three

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · Discover how liquid cooling enhances energy storage systems. Learn about its benefits, applications, and role in sustainable power solutions.

Thermophysical heat storage for cooling, heating, and power generation

Feb 5, 2020 · The role of energy storage is to resolve the time-scale mismatch between supply and demand, which plays a key role in high-efficiency and low-carbon energy systems. Based

Liquid cooling design requirements for energy storage

Liquid cooling design requirements for energy storage systems Liquid cooling technology involves the use of a coolant, typically a liquid, to . anage and dissipate heat generated by energy

A review on liquid air energy storage: History, state of the art

Mar 1, 2021 · Abstract Liquid air energy storage (LAES) represents one of the main alternatives to large-scale electrical energy storage solutions from medium to long-term period such as

(PDF) Liquid Hydrogen: A Review on

Sep 17, 2021 · This paper reviews the characteristics of liquid hydrogen, liquefaction technology, storage and transportation methods, and safety

A review on the liquid cooling thermal management system

Dec 1, 2024 · Currently, the maximum surface temperature (T max), the pressure drop loss of the LCP, and the maximum temperature variance (T max-v) of the battery are often applied to

6 FAQs about [What is the general pressure of energy storage liquid cooling ]

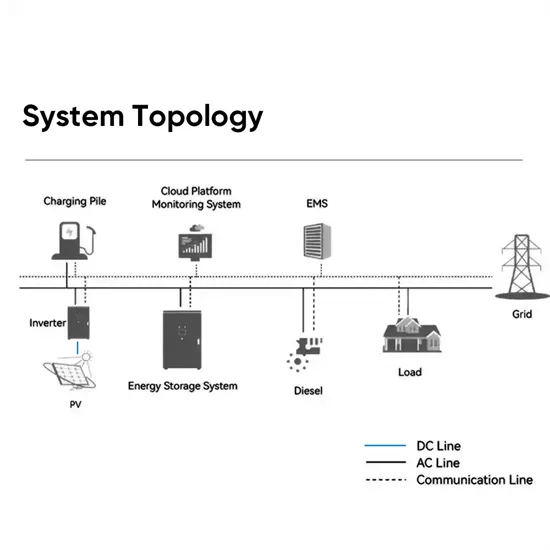

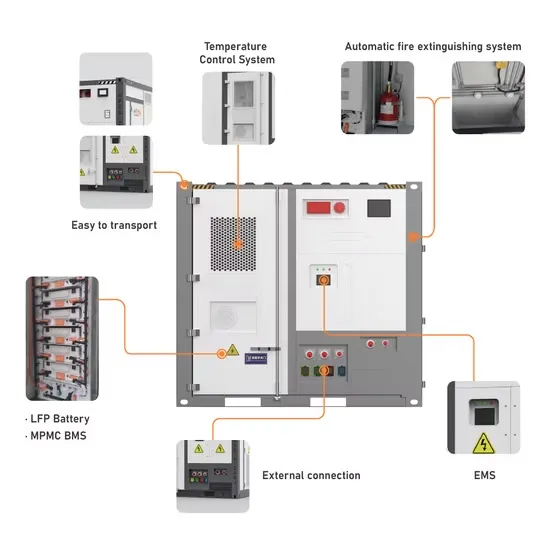

What is energy storage liquid cooling system?

Energy storage liquid cooling systems generally consist of a battery pack liquid cooling system and an external liquid cooling system. The core components include water pumps, compressors, heat exchangers, etc. The internal battery pack liquid cooling system includes liquid cooling plates, pipelines and other components.

Why is air cooling a problem in energy storage systems?

Conferences > 2022 4th International Confer... With the energy density increase of energy storage systems (ESSs), air cooling, as a traditional cooling method, limps along due to low efficiency in heat dissipation and inability in maintaining cell temperature consistency. Liquid cooling is coming downstage.

Why does air cooling lag along in energy storage systems?

Abstract: With the energy density increase of energy storage systems (ESSs), air cooling, as a traditional cooling method, limps along due to low efficiency in heat dissipation and inability in maintaining cell temperature consistency. Liquid cooling is coming downstage.

What is energy storage cooling?

Energy storage cooling is divided into air cooling and liquid cooling. Liquid cooling pipelines are transitional soft (hard) pipe connections that are mainly used to connect liquid cooling sources and equipment, equipment and equipment, and equipment and other pipelines. There are two types: hoses and metal pipes.

What is the internal battery pack liquid cooling system?

The internal battery pack liquid cooling system includes liquid cooling plates, pipelines and other components. This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection and design of the liquid cooling pipeline.

What is a liquid cooling pipeline?

Liquid cooling pipelines are mainly used to connect transition soft (hard) pipes between liquid cooling sources and equipment, between equipment and equipment, and between equipment and other pipelines. Pipe selection affects its service life, reliability, maintainability and other properties.

Industry Information

- Is there any battery cabinet manufacturer in Djibouti City

- How big is the energy storage cabinet for the 4100 energy storage battery pack

- Uganda heavy rain soaks supercapacitors in communication base stations

- Solar photovoltaic panels for agricultural applications

- Romanian system solar photovoltaic manufacturer

- How much is the Thimphusha outdoor power store

- Lilongwe UPS Uninterruptible Power Supply

- The power grid requires energy storage

- What is the current of the three 50KW inverters

- Battery Storage Profitability

- Imported battery cabinet installation site

- What waterproofing is used for double glass components

- Can the government invest in flywheel energy storage for communication base stations

- Inline circuit breaker for sale

- Large-scale power supply side energy storage

- 100 million photovoltaic panels generate electricity

- Composition of Tehran s modern energy storage system

- Container generator repair factory

- Lithuanian energy storage battery system manufacturer

- How much is the price of Lima smart energy storage battery

- High-power solar power generation and storage integrated machine

- Can water pumps absorb solar energy directly

- Kuwait City Photovoltaic Power Generation and Energy Storage Prices

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.