2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

Liquid cooling design requirements for energy storage

In the rapidly evolving field of energy storage, liquid cooling technology is emerging as a game-changer.With the increasing demand for efficient and reliable power solutions, the adoption of

Energy storage cooling system

Dec 8, 2024 · Compared with air-cooled systems, liquid cooling systems for electrochemical storage power plants have the following advantages: small footprint, high operating efficiency,

Liquid Cooling Energy Storage System | GSL Energy

Discover GSL Energy''s advanced liquid cooling energy storage systems for commercial and industrial applications. Scalable to 5MWh, certified by UL, CE,CEI and IEC. Improve energy

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · Higher cooling water flow velocity and lower cooling temperature are beneficial for the temperature uniformity of battery pack, with a cooling temperature controlled below 35 °C.

Energy storage pack design liquid cooling

CATL''''s Innovative Liquid Cooling LFP BESS Performs Well Under UL 9540A TestNINGDE, China, April 14, 2020 / -- Contemporary Amperex Technology Co., Limited

Profile energy storage liquid cooling solution

Profile energy storage liquid cooling solution 1. Effective Heat Dissipation: Liquid cooling systems use a coolant, typically water or a specialized fluid, to absorb

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · Liquid-cooled energy storage containers are versatile and can be used in various applications. In renewable energy installations, they help manage the intermittency of solar

Liquid Cooled BESS 1.6MW x 3MWh

2 days ago · 1.6MW x 3MWh MEGATRON - 20'' Commercial Liquid Cooled Battery Energy Storage System designed to for On-Grid applications.

Liquid Cooling Energy Storage: Top Companies Shaping the

Oct 28, 2023 · Let''s face it – traditional air-cooled energy storage systems are like trying to cool a volcano with a desk fan. As grid-scale projects balloon in size and battery densities skyrocket,

High-uniformity liquid-cooling network designing approach for energy

Nov 1, 2024 · A novel liquid-cooling network designing approach is proposed by graph-based genetic algorithm with high uniformity.

Thermal management performance and optimization of a

Jul 15, 2025 · Therefore, to broaden the thermal safety of energy storage battery pack, this work proposes a hybrid BTMS, which integrates topological fin design, passive PCM cooling, and

Liquid cooling vs air cooling

Aug 24, 2023 · Temperature has an impact on the performance of the electrochemical energy storage system, such as capacity, safety, and life, so

Energy storage cooling system

Dec 8, 2024 · Therefore, the liquid cooling system is more conducive to maintaining the performance and life cycle of the battery, and by increasing the operating hours and extending

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Meanwhile, in view of the insufficient energy-saving potential of the existing liquid cooled air conditioning system for energy storage, this paper introduces the vapor pump heat

Liquid Cooling in Energy Storage | EB BLOG

Oct 22, 2024 · Energy Storage Systems: Liquid cooling prevents batteries and supercapacitors from overheating, providing continuous operation.

Battery Cooling Tech Explained: Liquid vs Air

May 9, 2025 · Air Cooling or Liquid Cooling, Which is Suitable? Ultimately, the choice depends on scale and requirements. Air cooling remains viable for low

LIQUID COOLING SOLUTIONS For Battery Energy

Aug 3, 2022 · Active water cooling is the best thermal management method to improve the battery pack performances, allowing lithium-ion batteries to reach higher energy density and uniform

ESS Liquid Cooling System for Energy Storage

ESS Liquid Cooling System for Energy Storage Application Trumony can provide advanced liquid cooling technology for BESS solutions to dissipate heat more

Liquid Cooling in Energy Storage | EB BLOG

Oct 22, 2024 · Liquid cooling''s rising presence in industrial and commercial energy storage reflects an overall trend toward efficiency, safety, and

What is Immersion Liquid Cooling Technology in Energy Storage

Dec 11, 2024 · Immersion liquid cooling technology is an efficient method for managing heat in energy storage systems, improving performance, reliability, and space efficiency.

Principles of liquid cooling pipeline design

3 days ago · Energy storage liquid cooling systems generally consist of a battery pack liquid cooling system and an external liquid cooling system. The core

EMW series liquid cooling unit for energy

Battcool-C series air cooled chiller for energy storage container is mainly developed for container battery cooling in the energy storage industry. It is

Profile energy storage liquid cooling solution Archives

Profile energy storage liquid cooling solution:Advanced Cooling and Support Solution 1. Effective Heat Dissipation: Liquid cooling systems use a coolant, typically water or a specialized fluid, to

Battery Energy Storage

Active water cooling is the best thermal management method to improve battery pack performance. It is because liquid cooling enables cells to have a more uniform temperature

An optimization study on the performance of air-cooling

Jul 1, 2025 · In this study, a novel thermoelectric coupling model is used to numerically simulate the heat generation process of energy storage battery packs. Then, the impact of airflow

Why Are Liquid Cooling Battery Packs Essential? – XD Thermal

6 days ago · Why Are Liquid Cooling Battery Packs Essential? As the demand for efficient and reliable energy storage systems continues to rise, advancements in battery technology are

5MWh ESS: Envicool BattCool PACK + PCS Liquid Cooling Solution

Case Studies / 2024-03-12 5MWh ESS: Envicool BattCool PACK + PCS Liquid Cooling Solution On 11 March, the 14th CIES China International Energy Storage Conference was held at the

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

A lightweight and low-cost liquid-cooled thermal management solution

Feb 25, 2022 · A lightweight and low-cost liquid-cooled thermal management solution for high energy density prismatic lithium-ion battery packs

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which Cooling

Jul 23, 2025 · Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance,

CT-Energy Storage Temperature Control Full

This product is suitable for PACK & PCS full liquid cooling solutions. While ensuring heat dissipation for the PACK, it also provides liquid cooling for the

Smart Cooling Thermal Management Systems

Apr 30, 2025 · In this post, we''ll explore three popular battery thermal management systems; air, liquid & immersion cooling, and where each one

Liquid Cooling Energy Storage: Why It''s the Coolest

Jan 21, 2025 · Now, imagine that same heat challenge for large-scale energy storage systems. As renewable energy adoption surges, managing the thermal stress of batteries has become a

Counterflow canopy-to-canopy and U-turn liquid cooling solutions

Feb 1, 2024 · This work documents the liquid cooling solutions of Li-ion battery for stationary Battery Energy Storage Systems. Unlike the batteries used in Electri

Liquid Immersion Cooling for Battery Packs

Jul 21, 2025 · With higher energy density and fast-charging demands in modern EVs and energy storage systems, traditional air and indirect liquid cooling

InnoChill''s Liquid Cooling Solution:

Dec 20, 2024 · Discover how InnoChill''s liquid cooling solution is transforming energy storage systems with superior heat dissipation, improved battery life,

Air and Liquid Cooling Solar Energy Battery storage System

May 23, 2025 · For different projects of different energy storage integrators, the thermal management solutions vary greatly. For liquid cooling host suppliers, their core competitive

6 FAQs about [Energy storage pack upper and lower liquid cooling solution]

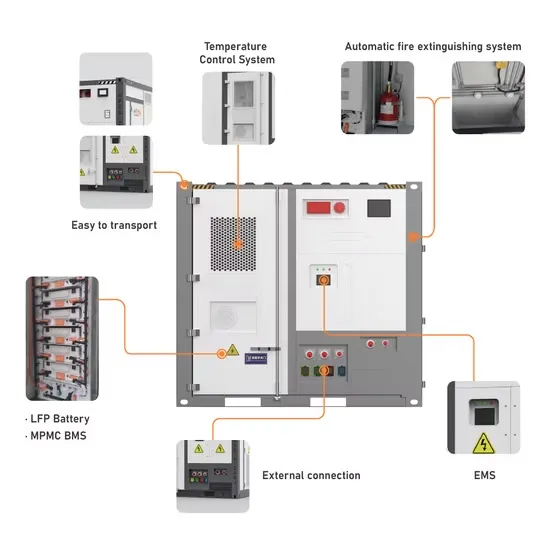

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

Industry Information

- Solar PV Panel Inverter in Zimbabwe

- Energy storage photovoltaic power station 5000 watts

- Bandar Seri Begawan lithium battery pack equipment

- Majuro lithium battery energy storage equipment

- Solar PV Panel Prices in Northern Cyprus

- How many watts is the brightness of rural solar street lights

- Lithuania Energy Storage Power

- Vilnius Northwest Energy Storage Implementation Plan

- Honiara Solar System

- Bangji 12v inverter

- Ghana Energy Storage Power Supply Manufacturer

- Photovoltaic inverter sc

- How much does a photovoltaic inverter cost in Busan South Korea

- How much power does a 665 watt photovoltaic panel have

- Quad circuit breaker in China in Myanmar

- Alofi wind power energy storage system price

- Energy storage container automatic clustering

- Montevideo Large Battery Energy Storage Station

- Wholesale 500w solar inverter in Romania

- Vienna multifunctional energy storage power supply sales

- Factory price thermal breaker in Cebu

- Which brand has more battery cabinets in Warsaw

- New Energy Battery Energy Storage Transformation

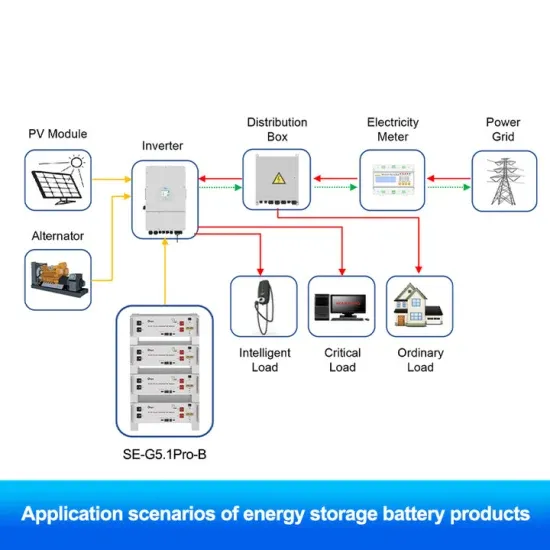

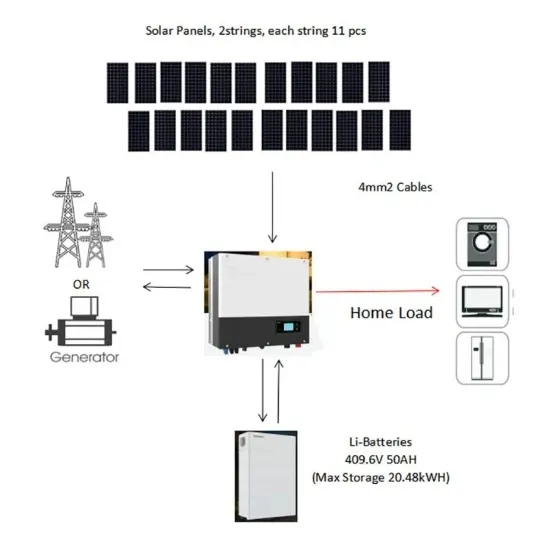

Commercial & Industrial Solar Storage Market Growth

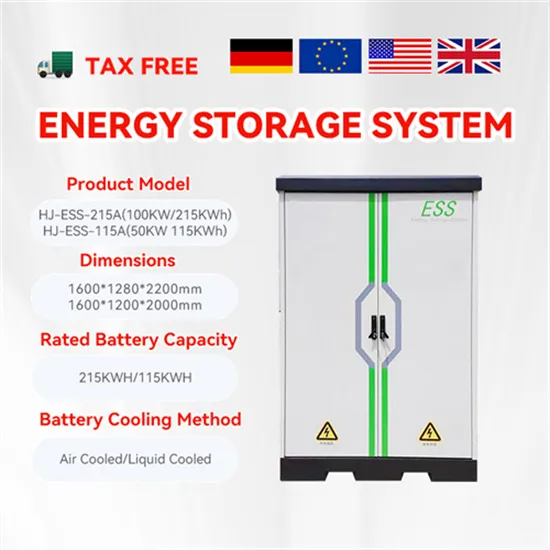

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.