Inside a Modern Lithium Battery Production Line

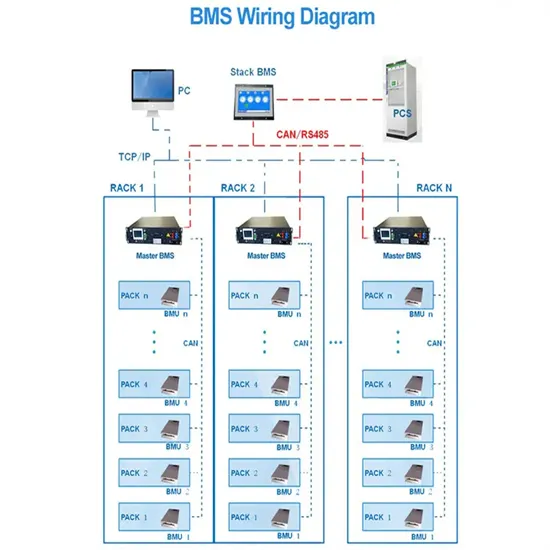

Mar 27, 2024 · Individual cells are integrated with other components like the Battery Management System (BMS), which acts as the brain of the battery pack. The BMS typically consists of a

Lithium Ion Battery Charging Cabinets

The new Justrite li-ion battery charging and temporary storage cabinets were designed to reduce the risks of battery fires and thermal runaway.

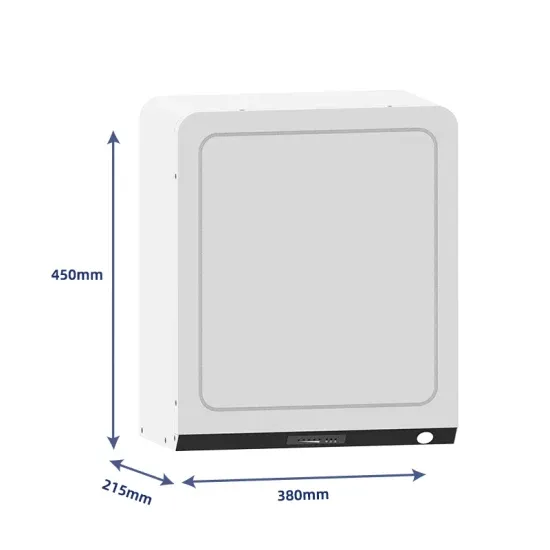

China Lithium Battery Storage Cabinet, Lithium Battery Storage Cabinet

The Lithium Battery Storage Cabinet is a top choice in our Power Distribution Cabinet & Box collection.When selecting a power distribution cabinet or box, important factors include size,

Safe Lithium-Battery Cabinets for Secure Storage

Apr 6, 2025 · Protect your lithium-battery storage with Guangsheng Technology''s specialized cabinets. Designed for safety and durability, meeting global standards. Ideal for industries and

Lithium battery capacity cabinet principle and maintenance

May 29, 2025 · The key to maintaining lithium battery capacity division cabinets is regular maintenance and overhaul. Including cleaning equipment, tightening connectors, checking the

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Principle and Design of Lithium Battery

Jan 14, 2022 · What is the principle of the lithium battery module protection circuit board, and how to design the lithium battery pack protection circuit board?

LITHIUM-ION BATTERY CHARGING AND

Yantai Gaoshengda Precision Machinery Company a professional battery cabinets manufacturer in China! Our main products are battery charging

PCB Packaging for Lithium Batteries: Design, Materials, and

Jan 15, 2025 · PCB packaging for lithium batteries refers to the design and implementation of printed circuit boards that physically house, electrically connect, and protect lithium battery

Justrite Lithium Ion Battery Storage Charging

Jul 23, 2024 · The Justrite Lithium-Ion Battery Charging Cabinet is the ultimate solution for safely charging and storing your lithium-ion batteries. Each

Lithium-ion Storage Cabinets | DENIOS

A lithium-ion cabinet, also known as a battery charging cabinet or battery safety cabinet, is a special fireproof storage unit designed to charge and safely store

Lithium battery charging cabinet circuit

The 12 Station Lithium-ion Battery Charging Storage Cabinet offers secure storage and charging for Lithium-ion batteries. Designed for high-demand environments, it features three 240V

Environmental footprint assessment of China''s lithium iron

Jun 24, 2025 · Purpose With the rising demand for lithium iron phosphate batteries (LFPB), it is crucial to assess the environmental impacts of their production, specifically in the

Lithium battery energy storage cabinet processing

Our cutting-edge battery charger cabinets, seamlessly integrated within our Lithium-Ion Energy Storage Cabinet lineup, ensure secure and fire-resistant containment during battery charging.

Lithium-Ion Battery Charging Cabinet | Securall

Protect your facility and your team with Securall''s purpose-built Battery Charging Cabinets—engineered for the safe storage and charging of lithium-ion, lead-acid, and other

Lithium‑Ion Protection Boards: PCB vs PCM vs BMS

May 16, 2025 · PCB (Protection Circuit Board): Basic voltage and current cutoff. PCM (Protection Circuit Module): PCB with passive balancing resistors. BMS (Battery Management System):

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

The process of making circuit boards from lithium batteries

In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting with a brief overview of existing Li-ion

Can You Use a Lithium Battery Without a

May 21, 2025 · A lithium battery protection board (PCB) is a small circuit module that acts as the battery''s security system. Its main function is to prevent

锂离子电池保护板及BMS知识|特瑞泰克

在上一篇文章中,我们介绍了 全面的锂离子电池技术知识,这里我们开始进一步介绍锂电池保护板和BMS技术知识。 这是一份来自 Tritek 研发总监的总结的综

Comprehensive Guide to Lithium Battery PCBs

Oct 17, 2022 · To know about lithium batteries, you will understand the structure of a lithium battery module PCBA (printed circuit board assembly, a custom

How to Choose The Best Protection Board For

Master lithium battery safety with protection boards and BMS. Learn how to select the best board for your device.

What is a Battery PCB? Protection Circuit Board

Apr 4, 2025 · Explore battery PCB protection boards for Li-ion & Li-Po batteries at FS Circuits. Prevent overcharging, over-discharging, and short circuits for

Li Ion Battery Pack Circuit Diagram – Wiring Flow

A Li-Ion battery pack circuit diagram is a visual representation of the individual cells and their interconnections within the battery pack. The diagram shows

TU Energy Storage Technology (Shanghai) Co., Ltd

From core chip selection to system-level architecture, we guarantee the safety and reliability of battery products in an all-round and real-time manner.

All Things You Should Know About BMS PCB

Oct 13, 2023 · A BMS PCB (Printed Circuit Board) is the core component of a BMS, responsible for monitoring, controlling, and protecting the battery pack.

Lithium Ion Battery Storage Cabinet | Storage Cabinet Supplier

We are a supplier of high-quality Lithium Ion Battery Storage Cabinet, featuring a powder-coated steel chamber with self-closing, oil-damped doors for safe storage and controlled battery

Understanding the Lithium

Mar 17, 2025 · But what exactly is it? A lithium - battery aging cabinet, also known as a battery formation and aging system, is a specialized piece of equipment designed to subject newly

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The ''Production Process of a Lithium-Ion Battery Cell'' guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode

Do Lithium-Ion Battery Packs Have Circuit Boards?

Feb 13, 2025 · Learn how circuit boards in lithium-ion battery packs work, their role in safety, and how to choose the best BMS for your needs.

A Guide to Designing A BMS Circuit Diagram for

Jan 17, 2024 · I have 3 of these circuit units collected on a single board, which lets me charge 3 lithium-ion battery banks simultaneously. In theory, you could

6 FAQs about [Lithium battery station cabinet circuit board production]

What is the production process of a lithium-ion battery cell?

The ‘Production Process of a Lithium-Ion Battery Cell’ guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode manufacturing to cell assembly and cell finishing. Furthermore, current trends and innovation of different process technologies are also explained.

Who makes lithium battery PCBs?

Lithium battery PCBs belong to automotive PCBs, and in the PCB industry, automotive PCB manufacturers must have the IATF 16949:2016 certification. Frankly speaking, currently, Chinese factories have better manufacturing technologies for lithium batteries and electric car charging stations than factories in any other country in the world.

Where can I buy a PCB for a lithium battery?

For lithium batteries, you can have the PCBs manufactured and assembled by the one-stop automotive PCB manufacturer PCBONLINE. PCBONLINE can also provide value-added manufacturing, including conformal coating and box build assembly, and delivers ready-to-use lithium batteries.

What are the features of lithium battery PCBs?

Anti-vibration is another vital feature of lithium battery PCBs. Electric vehicles run on the roads, and not only the whole lithium battery module but also the whole car should be designed with anti-vibration for safety. In regards to the quality standard of lithium battery PCBs, it is the ISO 16949 quality system.

What is a lithium battery PCBA?

A lithium battery PCBA is composed of many small lithium-ion batteries connected in series and rows, FR4 and flex PCBs mounted with required electronic components, and a battery management system (BMS). Inside the BMS, there is also a PCB. What are the PCBs and the BMS used for?

Can a cam engineer design a lithium battery PCB?

If you want lithium battery PCB design, the CAM engineer from PCBONLINE can design the PCB for your project. PCB manufacturing and assembly from PCBONLINE are certified with ISO 9001:2015, IATF 16949:2016, IPC, RoHS, REACH, and UL.

Industry Information

- Main specifications of double-glass modules

- Factory self-use energy storage power station

- What to do if the electricity bill for 5g base stations is expensive

- Old circuit breaker in China in Sao-Paulo

- China power breaker switch for sale producer

- Does flywheel energy storage generate electricity on its own

- Cube New Energy Storage Battery

- Battery Energy Storage in Serbia

- High quality 5kwh solar battery

- Flywheel Energy Storage in Cameroon

- Are cylindrical lithium battery cells the worst

- Is Macedonia s energy storage battery a lithium battery

- Kinshasa Photovoltaic Energy Storage Project

- Basic uses of Huawei energy storage power supply

- Tourism outdoor power supply 50 degrees

- Hybrid electrochemical energy storage

- Outdoor Multi-Tool Battery

- What brand of inverter should I use with lithium batteries

- Buy a small solar water pump

- How much is the wholesale price of photovoltaic folding container in Burundi

- Does the wind power station next door have batteries

- Managua Commercial Energy Storage Device Company

- Is it good to install solar panels on the roof of a container house

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.