FMEA-Graph-Based Approach for the Identification of

Jun 20, 2025 · Recent fire incidents involving electric vehicles have raised concerns about the reliability of lithium-ion battery systems. These events highlight the need for

Free FMEA Templates: DFMEAs, PFMEAs, System

Sep 19, 2024 · Download FMEA templates in Excel, Microsoft Word, Adobe PDF, Google Docs & Google Sheets. Includes PFMEA, DFMEA, System FMEA.

8 Best FMEA Software for Risk Analysis in 2025

May 16, 2025 · Want to manage and monitor testing activities? Here we explore some best FMEA software for ensuring risk analysis and high-quality testing of

What Are Flow Batteries? A Beginner''s Overview

Jan 14, 2025 · Want to understand flow batteries? Our overview breaks down their features and uses. Get informed and see how they can benefit your energy needs.

Energy Storage System Safety: Plan Review and

Apr 4, 2017 · Does Not Comply Not Observable N/A N/A Not Applicable Signage indicating containment and/or neutralization means provided for incident response mechanisms and any

Free FMEA Template — Failure Mode and Effect

Apr 7, 2025 · FMEA is a process risk analysis used to evaluate new and altered processes by predicting potential failures and mitigating risks from their

How to do FMEA for Medical Devices: Step-by

May 15, 2025 · Step 1: Define Scope and System Boundaries Start the FMEA by defining the system, subsystem, or component under analysis. Clearly

Quantitative Failure Mode and Effect Analysis for Battery

Mar 14, 2024 · End-to-end, streamlined battery control and management (BCM) based on materials properties, electrode architecture, electrolyte composition, cell balance,

Root Cause Analysis in Lithium-Ion Battery

Jun 5, 2020 · The production of lithium-ion battery cells is characterized by a high degree of complexity due to numerous cause-effect relationships between

Large-scale energy storage system: safety and

Sep 5, 2023 · The oxidation and reduction reactions at the electrodes generate an aggregate potential difference and subsequently, electron flow in the external

What is FMEA? Failure Mode & Effects Analysis

Overview Also called: potential failure mode and effects analysis; failure modes, effects and criticality analysis (FMECA) Failure mode and effects analysis

FMEA Analysis in Lithium-ion Batteries

Design Failure Mode and Effects Analysis (DFMEA) is a structured approach for identifying potential design-related failures of products and their implications.

Energy Storage FMEA: A Comprehensive Guide to Risk

May 29, 2019 · lithium-ion batteries can be drama queens. One minute they''re powering entire cities, the next they''re throwing thermal tantrums. This is where energy storage FMEA (Failure

Failure Analysis in Lithium-Ion Battery Production with

Dec 14, 2020 · In this paper, a method is presented, which includes expert knowledge acquisition in production ramp-up by combining Failure Mode and Effects Analysis (FMEA) with a

Guide: Failure Modes And Effect Analysis

4 days ago · FMEA (Failure Modes and Effects Analysis) is a proactive tool used to identify potential failures in a process, assess their impact, and prioritize

Failure Mode and Effect Analysis of Automotive

Jul 22, 2017 · Failure Mode and Effects Analysis (FMEA) technique is used to identify the potential failure modes, estimates the causes and its effects, and determine what could eliminate or

Safety Analysis of Lithium-Ion Cylindrical

Jan 17, 2024 · Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes.

A failure modes, mechanisms, and effects analysis (FMMEA)

Nov 1, 2015 · In a separate study, Hendricks et al. [7] carried out an FMEA analysis on battery failures, emphasizing how this process facilitates the implementation of enhanced control

A risk analysis method for potential failure modes in the

Aug 3, 2025 · To enhance product quality and operational safety of lithium-ion batteries, this paper proposes a risk analysis method based on an optimized Failure Modes and Effects

Booklet No. 14 Failure Mode and Effects Analysis FMEA

May 9, 2020 · The FMEA is an internationally recognized method of qualitative risk analysis [1], [2], [6]. At Bosch, it is enshrined in the product engineering process, and is used for the

Potential Failure Mode and Effects Analysis

May 23, 2008 · ___System (Design FMEA) ___Subsystem _X_Component: Connector System Design Responsibility: Workgroup Model Year/Vehicle(s): / 42 VOLT SYS Key Date: October

A Review of the Iron–Air Secondary Battery for

Sep 26, 2014 · Recent interest in the iron–air flow battery, known since the 1970s, has been driven by incentives to develop low-cost, environmentally friendly

DFMEA

Mar 30, 2022 · DFMEA is an analytical methodology that focuses on design failure, used in the product design and development phase to improve product

What are the Types of FMEAs? DFMEA, PFMEA,

Sep 21, 2024 · FMEA, DFMEA, PFMEA, FMECA. View our guide to Failure Mode & Effects Analysis to learn the differences, benefits, & how to perform a FMEA.

Safety Analysis of Lithium-Ion Cylindrical

Jan 17, 2024 · Addressing the safety issues of lithium-ion batteries is required in the design and manufacturing processes to reduce the frequency of failures

Comprehensive Analysis of Critical Issues in All

Jun 3, 2022 · Then, a comprehensive analysis of critical issues and solutions for VRFB development are discussed, which can effectively guide battery

FMEA Template

4 days ago · Download the comprehensive FMEA (Failure Modes and Effects Analysis) template to systematically evaluate and mitigate risks in your

FMEA Guide: Failure Mode and Effects Analysis

Apr 23, 2025 · Master FMEA—Failure Mode and Effects Analysis—with this step-by-step guide, RPN scoring tips to identify root problems and improve reliability..

Microsoft PowerPoint

Dec 8, 2021 · Utilize outputs from FMEA and Battery Discharge Procedure projects Utilize expertise and resources from NHTSA and Volpe Electronics Reliability Groups Technical

Microsoft Word

Jan 2, 2024 · The above flow chart illustrates the information flow when an engineering team performs a FMEA. The downward arrows represent the main flow and the upward arrows

Fuzzy logic approach for failure analysis of Li-ion battery

Jul 1, 2023 · This paper presents a Fuzzy FMEA for risk assessment of an immersion-cooled battery pack (ICBP) in electric vehicles. As a new technology, immersion cooling can facilitate

A risk analysis method for potential failure modes in the

Aug 19, 2025 · To enhance product quality and operational safety of lithium-ion batteries, this paper proposes a risk analysis method based on an optimized Failure Modes and Efects

6 FAQs about [Flow Battery FMEA]

What is DFMEA in battery design and development?

A reference degradation and aging mechanism shown below can be used to initiate a thorough DFMEA for the batteries under design and development. Design Failure Mode and Effects Analysis (DFMEA) is a structured approach for identifying potential design-related failures of products and their implications.

What is failure mode and effect analysis (FMEA)?

Needs: Failure analysis (FA ) and failure mode and effect analysis (FMEA) is important to guide cell design and qualification. Approach: Quantitative electrochemical analytic diagnosis (eCAD) to address currently qualitative diagnosis and to significantly accelerate progress in cell design for better cycle life, reliability and safety

What is DFMEA and PFMEA?

This study conducts a design and process failure mode and effect analysis (DFMEA and PFMEA) for the design and manufacturing of cylindrical lithium-ion batteries, with a focus on battery safety. 1. Introduction

What does FMEA stand for?

Applications Outline To support quantitative analyses on battery reliability and safety: Needs: Failure analysis (FA ) and failure mode and effect analysis (FMEA) is important to guide cell design and qualification.

How does DFMEA PFMEA affect battery safety?

From the integrated DFMEA–PFMEA, we have identified that localized heating and a short circuit increase the risk of thermal runaway, whereas increased gas generation due to moisture or electrolyte leakage increases the risk of explosion. Manufacturing and assembling defects in the safety devices also reduce the safety of the battery.

Why is DFMEA important for lithium-ion batteries?

When applied to lithium-ion batteries, DFMEA offers a comprehensive understanding of the potential risks associated with their design, enhancing safety and reliability. With the widespread use of lithium-ion batteries in various applications, ensuring their safety has become very essential.

Industry Information

- China furnace circuit breaker in Tanzania

- Lithium batteryLithium battery packPower battery

- The necessity of electrochemical energy storage

- India Mumbai outdoor power supply can

- Base station power cabinet quota

- Energy storage system overcurrent protection

- Naypyidaw Energy Storage Container

- Zambia Solar Fan

- Equipment required to assemble lithium battery pack

- What inverter to use for a set of batteries

- Superconducting battery energy storage

- Japanese container photovoltaic energy storage

- Photovoltaic panel voltage 36v charging 24v battery

- Energy storage equipment construction work

- Amman Wind Power Energy Storage Project

- 24v30a through inverter

- 240w outdoor power supply

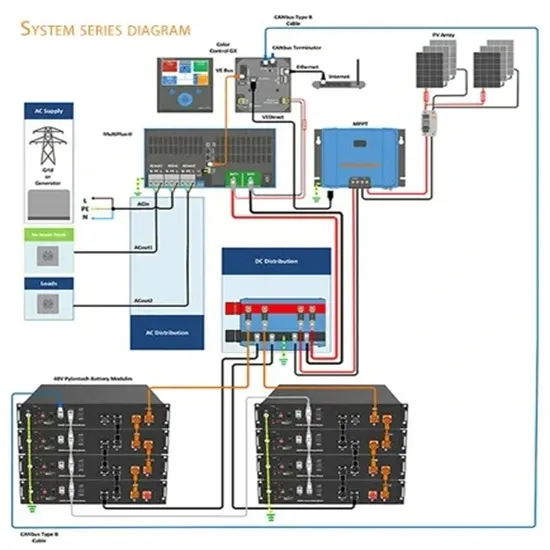

- Off-grid integrated energy storage system

- Wind Solar and Storage Integrated Energy Project

- Outdoor Power Solar Combination

- Battery power supply for 5G base stations in Switzerland

- Factory price incomer breaker in Senegal

- Dakar 90mw photovoltaic energy storage power station

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.