Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Discover the components and benefits of battery storage cabinet systems, including lithium-ion advantages, placement considerations, ventilation needs, and cost

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with

Installation Procedure

Remove the Empty Classic Battery Cabinet from the Pallet. Position the Empty Classic Battery Cabinet. Mechanical installation. Follow one of the procedures: Mechanical Installation for

Eaton 93PM L (208V) UPS and Samsung Gen 3 Battery

May 1, 2025 · The installation manuals of the UPS and battery cabinet describe how to install and operate the Eaton 93PM-L (208V) UPS and battery cabinets. Read and understand the

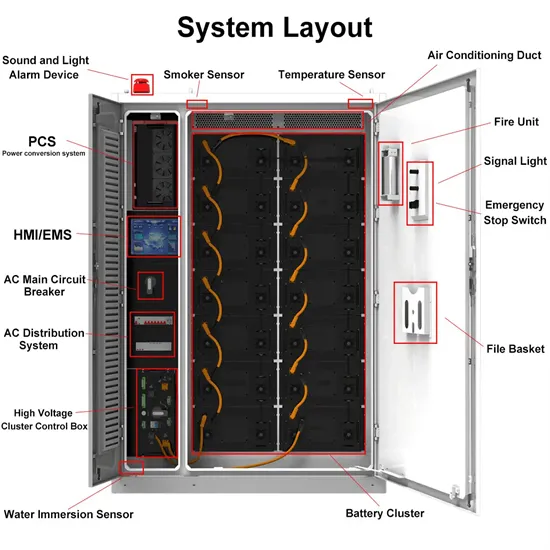

How to design an energy storage cabinet: integration and

Jan 3, 2025 · The following are several key design points: Modular design: The design of the energy storage cabinet should adopt a modular structure to facilitate expansion, maintenance

BC58 Battery Cabinet Installation, Operation,

Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Lithium battery cabinet installation process

Installation Procedure. Prepare for Installation; Install the Rear Seismic Anchoring; Position and Interconnect the Battery Cabinets; Install the Front Seismic Anchoring; Install the Battery

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · Lithium-ion Battery Module and Pack Production Line Process Flow The lithium-ion battery module and pack production line is a complex

The Complete Guide to Installation of Energy Storage Battery Modules

Jun 1, 2025 · Imagine building a Ferrari engine with IKEA instructions – that''s what happens when energy storage battery modules get installed without proper protocols. As renewable energy

Q-LS-ST Installation and Operation Manual

May 23, 2025 · The Q-LSB battery module is a single-wide cabinet containing (2) strings of (29) SLA Batteries, 12V, 26Ah, distributed among (8) cabinet sections or slide-out locking trays

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Battery cabinet installation construction process

bserving the relevant accident prevention rules). Place cells or block batteries into the cabinet according to In this guide, we will introduce the correct installation steps after receiving the

Method Statement for Installation of Central

The following procedure will be followed for installation of Central Battery system and can be customized as per the specific needs for different projects.

Galaxy Lithium-ion Battery Cabinet

Jan 2, 2025 · Read these instructions carefully and look at the equipment to become familiar with it before trying to install, operate, service or maintain it. The following safety messages may

100kW 215kWh All-in-One Battery Storage

The iCON 100kW 215kWh Battery Storage System is a fully integrated, on or off grid battery solution that has liquid cooled battery storage (215kWh), inverter

Generac PWRcell Outdoor Rated (3R) Battery Cabinet : Install

PAGE 34 Wiring Diagrams PWRcell 17 BLACK RED Contactors Snubber Battery String DC I/O Switch Black-start battery GRB REbus 380v DC REbus cable entrance Module CAT5 COMs

Smart battery cabinet installation tutorial diagram

Added precautions in 1.2 Battery Safety. Added precautions in 5.8 Installing Battery Modules. Updated 5.11 Sealing Cabinets. 17 2023-10-16 Added the description about the leakage

How to correctly install lithium battery energy

Mar 25, 2024 · Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid auxiliary services

Battery Cabinet

Feb 28, 2025 · Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the

Battery Cabinet

A maximum of three battery groups in up to six battery cabinets can be deployed inside the smart module. If many batteries are configured, they can be deployed outside the smart module. If

How to correctly install lithium battery energy

Mar 25, 2024 · In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps

Energy Storage Solution LFP Battery System

Jun 22, 2023 · Optimizing Energy Storage Systems Under Minimal Risk Delta''s battery storage systems feature high-voltage output for enhanced energy management efficiency. With their

Battery Module & Pack Manufacturing: Step-by

Apr 19, 2025 · The manufacturing process begins with individual Li-ion cells — typically cylindrical, pouch, or prismatic in form — which are rigorously tested

BATTERY CABINET DEVELOPMENT PROCESS

Battery cabinet installation construction process A battery enclosure is a housing, cabinet, or box. It is specifically designed to store or isolate the batteryand all its accessories from the external

Lithium battery cabinet installation instructions

Install the Battery Modules in the Battery Cabinet; Connect the Power Cables; Overview of Communication Interface; Route the Signal Cables to the Switchgear, Rack BMS, and System

Battery swapping station for electric vehicles

Vehicle entrance & exit and safety detection Common problems and technical difficulties When the vehicle enters the battery swapping station, the bottom

The Complete Guide to Installation of Energy Storage Battery Modules

Jun 1, 2025 · As renewable energy adoption surges (global market projected to reach $1.1 trillion by 2027 [4]), the installation of energy storage battery modules has become the make-or-break

Eaton 93PM Integrated Battery Cabinet-Small Welded

Mar 29, 2025 · The battery detect signal wiring from the battery cabinet must be connected to a programmed UPS building alarm in the 93PM (480V) UPS and to CN8 in the 93PM-L (208V)

Lithium-Ion Batteries | Industrial UPS Systems

That Battery Module (BM) The String Management System (SMU) The Battery Module BMS (BMS) Rack BMS The total battery cabinet chassis provides

Installation And Commissioning

Oct 18, 2016 · We recommend that batteries are properly installed in HBL battery racks or modules or HBL battery cabinets. The use of other operator-specific solutions may render the

Lithium Battery Energy Solution

Jan 27, 2025 · This manual describes how to install LG Chem EM048126P3S series lithium rack mounted battery modules into a supplied Cabinet and wire them to a supplied DC Distribution

Lithium battery module design production

Aug 18, 2025 · Power lithium battery module, a number of batteries in series and parallel through the conductive connectors into a power supply, through the

Installing Battery Modules

Before installing batteries, carefully read the safety precautions. Before installing batteries, ensure that the air conditioner in the battery room is started and that the ambient temperature and

Battery module cabinet entry process

A generic battery pack assembly bill of process that lays out the significant steps and challenges. Energy density fuses HV circuit LFP lg chem lithium Lithium Ion Lithium Iron Phosphate

6 FAQs about [Battery cabinet installation battery module process]

How do you connect a battery to a cabinet?

Route the ground bond wiring from the battery cabinet’s ground bond bolt, through the cabinet-to-cabinet wiring pass through to the adjacent cabinet’s ground bond bolt. 9. Connect the ground bonding wiring to the bolt and torque the ground bond wiring bolts to 10 Nm (7.38 lb-ft).

How do I wire the Eaton Samsung Gen 3 battery cabinets?

Only one ground conductor is required in each conduit. Use this procedure to wire the Eaton Samsung Gen 3 Battery Cabinets to the UPS cabinet. To install wiring to connections: Verify the UPS system is turned off and all power sources are removed. Refer to the applicable UPS Installation and Operation manual for UPS operating procedures.

How do I wire a UPS battery?

Refer to the battery cabinet manual for detailed instructions on conduit and battery wiring locations. Route the battery wiring (positive, negative, and ground) through the conduit from the DC terminals in the UPS over to the DC terminals located in the top of the battery cabinet.

How many battery modules does a ups have?

The System is housed in a one or two free–standing cabinets with safety shields behind the door and front panels. The UPS is available in 50 or 60 Hz with various output power ratings while the battery cabinet is available with 16 battery modules. The table below depicts the system model numbers and the stored energy capacity of the system.

What are the maintenance procedures for a UPS & battery system?

Maintenance procedures should specify that the bolted connections be retorqued to values listed in this manual. Annual preventive maintenance should be performed only by authorized service personnel familiar with maintenance and servicing of the UPS and battery system.

What is the difference between a ups and a battery cabinet?

The UPS is available in 50 or 60 Hz with various output power ratings while the battery cabinet is available with 16 battery modules. The table below depicts the system model numbers and the stored energy capacity of the system. The End of Discharge Voltage limit for each battery cabinet for all models is 400.8V DC. Table 3.

Industry Information

- Brunei has a communication base station inverter connected to the grid

- Belgrade 3000w solar power system wholesale

- Can Apiawa be equipped with solar energy

- Wholesale 2000 amp switchgear in Sweden

- Which is the best outdoor communication battery cabinet in Iraq

- Uninterruptible power supply sales in Palikir computer room

- The role of container photovoltaic panels in Port Vila

- Paraguay special energy storage battery price

- Which energy storage battery is more cost-effective

- Reliable energy storage containers for sale in France

- Mauritania Compression Energy Storage Power Station

- China 16kw sunsynk inverter factory exporter

- China factory price 220 amp breaker company

- Base station solar panel unit price

- Battery cabinet maximum charging power calculation

- Which telecommunications company has more base stations in Tripoli

- Uninterruptible Power Supply for Democratic Republic of Congo Telecom

- Energy Storage Fire Prevention System

- Kampala aluminum acid energy storage battery brand ranking

- Dhaka Photovoltaic Glass Shed BESS Information

- Lisbon Heavy Industry Energy Storage Cabinet Wholesaler

- Hot sale China drawout circuit breaker for sale

- Warsaw Electric Mobile 5G Base Station

Commercial & Industrial Solar Storage Market Growth

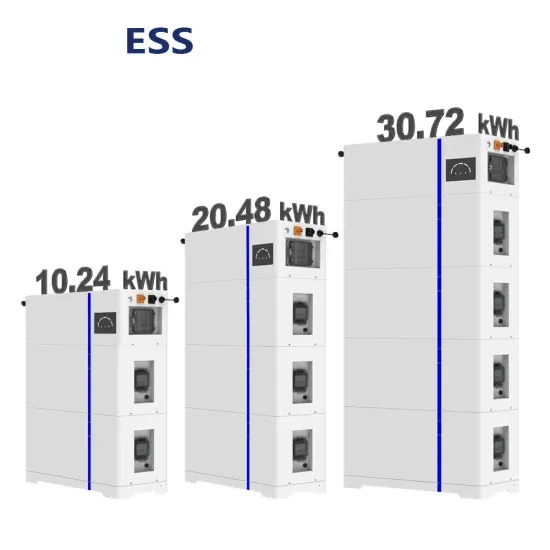

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.