Monocrystalline silicon photovoltaic panel specifications

Monocrystalline solar panels are produced from one large silicon block in silicon wafer formats. The manufacturing process involves cutting individual wafers of silicon that can be

Crystalline Silicon Photovoltaic Module Manufacturing

Feb 10, 2020 · Executive Summary Over the past decade, the crystalline-silicon (c-Si) photovoltaic (PV) industry has grown rapidly and developed a truly global supply chain, driven

What Is a Monocrystalline Solar Panel?

Aug 4, 2024 · Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

Monocrystalline Solar Panels: How They Work,

Sep 16, 2023 · Monocrystalline solar panels utilize monocrystalline silicon cells to transform sunlight into usable electrical energy. These cells are made from

Monocrystalline Silicon PV: 5 Advantages Over Alternatives

Jun 30, 2025 · Monocrystalline silicon panels consistently generate 8-15% more power in low-light conditions compared to polycrystalline and thin-film alternatives. When irradiance drops to 200

Comprehensive Guide to Monocrystalline Solar

Aug 13, 2025 · Related Article: Monocrystalline VS Polycrystalline Solar PV Modules How do Monocrystalline Solar Panels Work? Monocrystalline solar

What are the components of a PV system?

Apr 7, 2016 · Monocrystalline silicon solar cells. Polycrystalline silicon solar cells with higher conversion efficiencies. Amorphous silicon cells are the least

How Monocrystalline Solar Cells Work

May 10, 2012 · If you see a solar panel, the chances are it''s made of monocrystalline solar cells. They are by far the most widely used solar

Comprehensive Review of Crystalline Silicon

Dec 20, 2023 · This review addresses the growing need for the efficient recycling of crystalline silicon photovoltaic modules (PVMs), in the context of global

What Are The Main Components of Solar Panels?

Solar Panel Encapsulation Film Encapsulation films, also known as solar panel encapsulants, are essential components in solar panels. Positioned between

Total production costs for mono PERC c-Si solar components

Jul 4, 2025 · Total production costs for mono PERC c-Si solar components by input, 2022 - Chart and data by the International Energy Agency.

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two

Components of a Photovoltaic System

Oct 23, 2018 · Monocrystalline panels have a uniform crystal structure across the entire panel, and can be made from a variety of materials such as amorphous

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · How is a monocrystalline solar panel made Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by

Overview of life cycle assessment of recycling end-of-life photovoltaic

Jan 1, 2024 · Crystalline silicon (C–Si) photovoltaic (PV) modules are currently reaching the End-of-life (EOL) stage, and the environmental impact of recycling PV is of great concern. The life

Health and Safety Concerns of Photovoltaic Solar Panels

Oregon Department of Transportation Solar Highway photovoltaic solar panel selection The solar panels proposed for use in the Oregon Department of Transportation''s Solar Highway program

Solar Panel Components (List and Functions)

May 8, 2022 · Alternatively, some photovoltaic (meaning "solar-powered") materials can include copper indium gallium selenide, cadmium telluride,

Photovoltaic (PV) Cell Types | Monocrystalline,

5 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

Understanding the Composition of Solar Panels

Apr 7, 2023 · The photovoltaic (PV) cell is the heart of the solar panel and consists of two layers made up of semiconductor materials such as

Solar Photovoltaic Cell Basics

3 days ago · There are a variety of different semiconductor materials used in solar photovoltaic cells. Learn more about the most commonly-used materials.

What is Monocrystalline Solar Panel: A

Mar 23, 2024 · A solar panel is technically known as PV or photovoltaic panel because each comprises small, interconnected PV cells. By the way, do you

Experimental, economic and life cycle assessments of

Mar 15, 2022 · As seen in the figure, peaks at 37, 44, 64 and 77° correspond to the crystalline peaks of monocrystalline silicon (JCPDS No. 01-089-905), indicating and verifying that the

Components of a Solar Panel: Complete Technical Guide

1 day ago · Solar panel adoption has reached unprecedented levels in 2025, with over 3.2 million residential installations across the United States alone. As photovoltaic technology continues

Monocrystalline Silicon

Monocrystalline silicon is the most common and efficient silicon-based material employed in photovoltaic cell production. This element is often referred to as single-crystal silicon.

Monocrystalline silicon solar energy specifications

PV modules use pseudo-squared, high-efficiency, monocrystalline silicon cells (the cells are made of a single crystal of high purity silicon) to transform the energy of

Socio-Economic and Environmental Impacts of Silicon Based Photovoltaic

Jan 1, 2013 · Recycling of PV panel is currently not economically viable because waste volumes generated are too small; significant volumes of end-of-life photovoltaic panels will begin to

Life Cycle Greenhouse Gas Emissions of

Mar 19, 2012 · As the names suggest, monocrystalline silicon (mono-Si) PV cells are made from wafers cut from an ingot of single crystalline silicon and

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · Monocrystalline panels are composed of monocrystalline cells obtained by cutting slices of silicon ingots through the Czochralski system. This is a process in which a crystal

Experimental comparison between Monocrystalline,

May 11, 2022 · PV cells are made from semiconductors that convert sunlight to electrical power directly, these cells are categorized into three groups depend on the material used in the

Types of photovoltaic solar panels and their

Nov 6, 2017 · Instead of using silicon in crystalline form, they use a thin layer of photovoltaic material deposited on a substrate such as glass, plastic or metal.

Monocrystalline vs. Polycrystalline solar panels

Jan 9, 2023 · The two main types of silicon solar panels are monocrystalline and polycrystalline. Learn their differences and compare mono vs poly solar.

6 FAQs about [Photovoltaic panel components monocrystalline silicon]

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

What is the efficiency of a monocrystalline photovoltaic (PV) panel?

With an efficiency rate of up to 25%, monocrystalline panels reach higher efficiency levels than both polycrystalline (13-16%) and thin-film (7-18%) panels. Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

Is a monocrystalline solar panel a photovoltaic module?

Yes, a monocrystalline solar panel is a photovoltaic module. Photovoltaic (PV) modules are made from semiconducting materials that convert sunlight into electrical energy. Monocrystalline solar panels are a type of photovoltaic module that use a single crystal high purity silicon cell to harness solar power.

Why is monocrystalline silicon used in photovoltaic cells?

In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation. Monocrystalline silicon consists of silicon in which the crystal lattice of the entire solid is continuous. This crystalline structure does not break at its edges and is free of any grain boundaries.

How are monocrystalline panels made?

The manufacturing process for monocrystalline panels begins with melting raw silicon, which is then used to grow a single crystal silicon ingot (block of solid silicon) following a process called the Czochralski method, so named for the Polish chemist who discovered it.

What is the difference between monocrystalline and polycrystalline silicon substrates?

Monocrystalline silicon substrates are made from a single crystal of silicon, resulting in higher efficiency but also higher production costs. Polycrystalline silicon substrates, on the other hand, are composed of multiple silicon crystals and offer a more cost-effective option, albeit with slightly lower efficiency.

Industry Information

- Energy Storage Project Structure

- Outdoor power supply with wifi

- 1000W solar light price

- Mbabane large UPS uninterruptible power supply

- China 4000w solar inverter in China for sale

- Dublin Industrial Energy Storage

- 1 5 kw solar inverter factory in Melbourne

- High quality 240 volt breaker in Albania

- Roman Energy Storage Cabin Price Comparison

- Amman Energy Storage Container Supplier

- Palestine outdoor ip65 photovoltaic combiner box company

- 570 Solar Photovoltaic Panels

- Inverter with several lead-acid batteries

- Household wind and solar energy storage equipment

- How many watts does a 85V solar panel have

- Sophia Photovoltaic Energy Storage Battery Cabinet Solution

- Port Vila Industrial Energy Storage Products

- Wholesale 240v power station in Myanmar

- Democratic Republic of Congo BESS Uninterruptible Power Supply BESS

- Photovoltaic 380v inverter

- Luanda battery storage manufacturer

- Hybrid inverter mppt in China in Los-Angeles

- Prague 220v outdoor power supply brand

Commercial & Industrial Solar Storage Market Growth

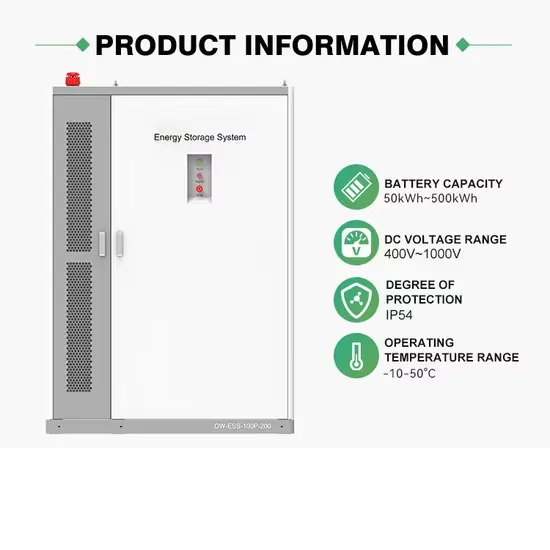

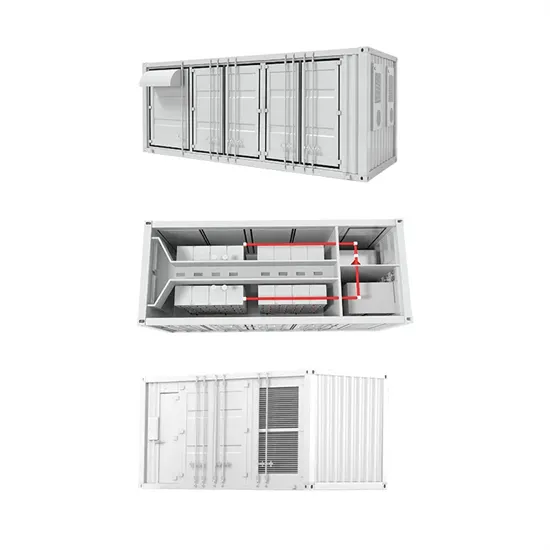

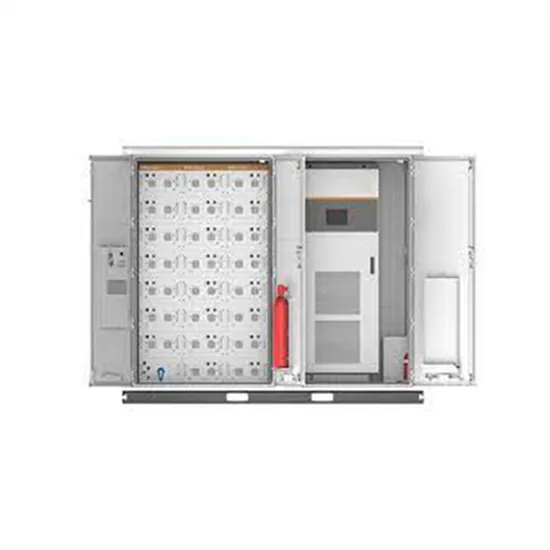

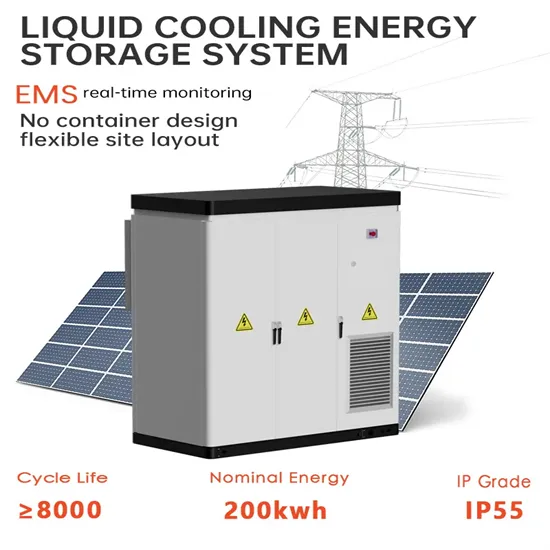

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.