Case Study– Battery Cabinet Application: Energy Storage

Mar 31, 2023 · Our battery cabinet is crafted for seamless assembly and disassembly, ensuring ease of use and maintenance. The cabinet''s thickness measures 1.5mm, providing a robust

Battery cabinets for maximum security | AIB Kunstmann –

Aug 16, 2025 · Your battery deserves a home that protects and thinks: TÜV-certified battery cabinets from AIB Kunstmann – strong, smart, and secure. Tradition meets innovation since

Lithium Battery Manufacturing Process Step-by

Aug 4, 2025 · Ufine Battery lithium battery manufacturing process: electrode prep, cell assembly an''d testing. Custom solutions for high-performance batteries.

Battery Storage Cabinets: The Backbone of Safe

Apr 11, 2025 · Explore the essential role of battery storage cabinets in modern energy systems, highlighting their design, safety features, and applications

Lithium battery energy storage cabinet production tutorial

This article discusses cell production of post-lithium-ion batteries by examining the industrial-scale manufacturing of Li ion batteries, sodium ion batteries, lithium sulfur...

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · There may be multiple ways to configure the cabinet, so consider all possible options. For instance, if a battery, rack and charger are required the system can be designed

Lithium battery energy storage cabinet production tutorial

Lithium secondary batteries store 150-250 watt-hours per kilogram(kg) and can store 1.5-2 times more energy than Na-S batteries,two to three times more than redox flow batteries,and about

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

What is a Lithium Battery Formation and Capacitance Tester Cabinet

Dec 26, 2024 · These cabinets are highly automated, with advanced control systems that can monitor and manage the charging and discharging processes of each individual battery or

Understanding the Lithium

Mar 17, 2025 · In the realm of lithium - battery production and quality control, the lithium - battery aging cabinet plays a crucial role. But what exactly is it? A lithium - battery aging cabinet, also

Battery Room Ventilation and Safety

Mar 15, 2023 · This safety factor is to allow for hydrogen production variations with changes in temperature, charge controller failure, and reduction in net volume of battery room due to

HOW TO BUILD A BATTERY STORAGE CABINET

How much does it cost to repair the energy storage battery panel In the cost table, we have estimated battery costs based on typical battery output as follows: battery power 7kW peak /

Storing Lithium Ion Batteries – Safe Charging

Storing li-ion batteries in the workplace can be dangerous if proper conditions aren''t maintained. Learn more about proper battery storage & charging.

Study on performance effects for battery energy storage

Feb 1, 2025 · The purpose of this study is to develop appropriate battery thermal management system to keep the battery at the optimal temperature, which is very important for electrical

Diverse Uses of Lithium Battery Formation Cabinets

Dec 26, 2024 · Discover the 5 crucial application scenarios of lithium battery formation and capacitance tester cabinets. From consumer electronics to electric vehicles, energy storage,

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Discover the components and benefits of battery storage cabinet systems, including lithium-ion advantages, placement considerations, ventilation needs, and cost

Forming Battery cabinet

Forming battery cabinets play a key role in the field of battery production and energy management. Its exquisite technology ensures the safe operation of the battery, and is widely

Customized Lithium-Ion Battery Storage

Rely on Wesgar to produce your customized, high-quality L-ion battery enclosures and take care of your unique needs.

Unveiling the Wonders of Cabinet Batteries: A

Apr 30, 2025 · What are Cabinet Batteries? Cabinet batteries, also known as battery cabinets, are self - contained units that house multiple battery cells or modules. They are designed to

Battery Energy Storage Cabinet Construction Process: From

Remember that Texas freeze in 2021? Storage systems that survived shared three features: heated cabinets, triple-sealed enclosures, and enough insulation to make a Yeti jealous. Now,

Battery Cabinets and Enclosures Manufacture

Aug 5, 2025 · Openex manufactures first-class battery enclosures and take care of your unique needs. Our quality custom battery storage cabinets are skillfully

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

How to design an energy storage cabinet: integration and

Jan 3, 2025 · Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and

Ventilation and Breathing of Battery Rooms

Mar 30, 2006 · Maintenance-free or "closed" batteries are installed in some UPS systems. batteries can be neither topped up with water nor maintained. The charging of a battery

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

The Ultimate Guide to Battery Charging

Feb 14, 2025 · Lithium-ion batteries power many of our everyday devices, from industrial machinery to personal electronics. However, they also pose

Battery cabinet development process

ess called battery pack production. In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step

Battery cabinet production design drawings

Unified Power offers a complete line of battery cabinets for both UPS and Telecom Applications. These cabinets can be configured to match OEM cabinets and offer a competitive option for

How to design an energy storage cabinet: integration and

Jan 3, 2025 · This article will introduce in detail how to design an energy storage cabinet device, and focus on how to integrate key components such as PCS (power conversion system), EMS

Energy Storage Cabinets: Key Components,

Aug 12, 2024 · Lead-Acid Battery Cabinet Lead-acid battery cabinets are well-known for their cost-effectiveness and reliability, though they offer lower

What are the companies that produce battery cabinets

4 Companies Leading The Rise Of Lithium And Battery Technology Batteries with NMC 811 cathodes and other nickel-rich batteries, require lithium hydroxide. 5 By 2021, the company

How to Produce Energy Storage Equipment Cabinets: A

From Blueprint to Reality: Understanding the Nuts and Bolts Let''s cut through the jargon - producing energy storage cabinets isn''t just about welding metal boxes. It''s like building the

Is it tiring to produce lithium battery cabinets in the

This lithium battery charging cabinet is used to safely store and charge lithium-ion batteries in the workplace. This cabinet features 18 charging outlets and an in-built containment sump. When

How to Choose the Right Battery Cabinet for Your Needs

Jan 30, 2025 · Choosing the right battery cabinet can be a daunting task, especially with all the options available today. If you need to store batteries for home, a workshop, or a business,

How to Build a Battery: An In-Depth

Dec 17, 2024 · Batteries are essential in various applications, from consumer electronics to electric vehicles. Understanding how to manufacture different

6 FAQs about [How to produce battery cabinets]

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How do you choose a battery cabinet?

Again, the door should have a safe locking mechanism or latch. In more advanced battery cabinets, they may have alarm systems. Ventilation systems – they may integrate louvers. Depending on the enclosure design, the ventilation systems can be at the top or bottom section. Ventilation systems also help during the cooling process.

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

What is energy storage cabinet?

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

Industry Information

- Off grid solar power inverter in Mexico

- Tanzania energy storage low temperature lithium battery

- How to charge the battery at the energy storage cabinet site

- The growth rate of household photovoltaic energy storage in Africa

- Best home battery storage for sale Factory

- Wind Solar Diesel and Storage Integrated Operation Station

- 1kWh cheap outdoor power supply

- Outdoor power lighting battery life

- How much does a Dakar container energy storage station cost per square meter

- Photovoltaic inverter fixed

- 2500 watt 24 volt inverter

- Ljubljana energy storage battery bans lithium batteries

- Israel Solar Base Station Factory

- How much does a Berlin industrial and commercial energy storage cabinet cost

- Photovoltaic inverter capacity introduction

- Uzbekistan Tampa 220V inverter

- Slovenia single phase 50kw off grid inverter

- 5G base station energy storage power trading

- Energy storage application in New York Industrial Park USA

- Nicosia 2025 Communication Base Station Inverter

- Liberia outdoor communication battery cabinet new energy

- Extra Large Solar Panel 1000W Solar Light

- High quality China 500 watt solar inverter producer

Commercial & Industrial Solar Storage Market Growth

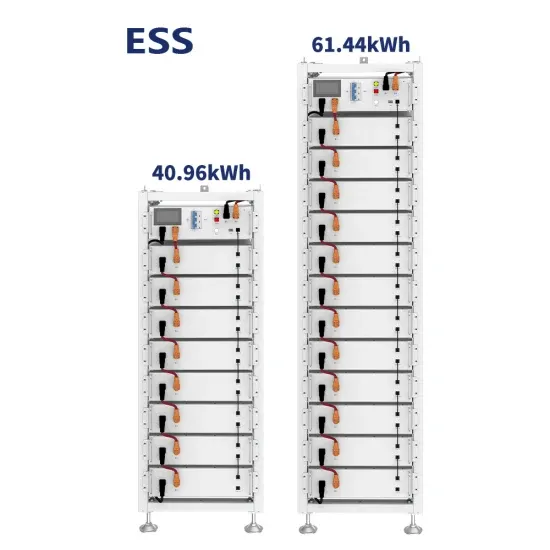

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.