End-of-life pathways for photovoltaic backsheets

The recoverable valuables include aluminum, copper, and glass, which are already being recycled today. The hazardous substances are cadmium,

Assessment of toxicity tests for photovoltaic panels: A review

Jun 1, 2024 · The installed capacity of photovoltaic solar energy is on the rise, which will lead to significant amounts of end-of-life solar panels in the future.

Determination of leachable arsenic from glass ampoules

Aug 26, 2017 · Appreciable amounts of different arsenic compounds are used in the manufacture of glass and glass ampoules (injection vials and bottles) used to store drugs. Exposure/intake

Release: ESIA Recommendation Paper

Oct 6, 2023 · Given that glass constitutes a substantial portion of PV module weight, recycling glass proves environmentally beneficial by reducing CO 2

Are Solar Panels Are Filled with Toxic Chemicals that Leach

Nov 16, 2024 · Here''s the breakdown. Solar panels are mostly made of glass, aluminum and silicon – 77%, 10% and 3%, respectively. It''s true that trace elements are added to make them

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Solar Glass & Mirrors Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the

Europe remains largest importer of Chinese

Feb 20, 2023 · China recorded new highs in output value and the export of photovoltaic (PV) products in 2022, with Europe remaining the most important

Harmful lead in photovoltaics

Jan 17, 2020 · Without globally unified standards in waste management, the risk from toxic materials such as lead will become increasingly important.

Photovoltaic Glass Waste Recycling in the Development of Glass

Apr 3, 2023 · PVWG was recovered from photovoltaic house roof panels for developing windows glass substrates; PVWG was used as the main material mixed with other industrial waste

Glass Application in Solar Energy Technology

Apr 28, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and

(PDF) An overview of solar photovoltaic panels''

Jan 3, 2025 · Solar PV panels contain zinc, lead, mercury, arsenic, cadmium, selenium, indium, gallium, fluorine, and other elements, which pose

Solar: end-of-life panels revalued in the glass industry

Oct 16, 2024 · This is a first on an industrial scale: glass from end-of-life photovoltaic panels will be used to manufacture flat glass, this glass mainly intended for the construction and

Arsenic vitrification by copper slag based glass: Mechanism

Jul 1, 2017 · The FTIR spectrum of the glasses have revealed that the arsenic exists in the form of AsO 4 tetrahedra and the Q n structure of the copper slag based glass has been strengthened

Photovoltaic (PV) Modules (Including Solar Panels) Universal

A PV module is defined as a device consisting of, or containing, one or more electrically connected photovoltaic cells that are designed to convert solar radiation into electrical energy.

What is the arsenic content of photovoltaic glass exported

Do PV modules contain arsenic chromium? We have not found any evidence that either of these PV technologies contain arsenic, gallium, germanium, hexavalent chromium or perfluoroalkyl

Addressing uncertain antimony content in solar glass for

Nov 7, 2023 · Glass accounts for a significant propor on of PV module weight, making glass recycling an environmentally beneficial process due to reduced CO2 emissions and energy

Toxic Materials Used in Thin Film Photovoltaics

Jan 8, 2020 · Thin film PV (TFPV) technology contains a higher number of toxic materials than those used in traditional silicon PV technology, including

Advancements in Photovoltaic Glass Technology

Aug 19, 2025 · Implementing PV glass technology requires careful planning, financial investment, and a willingness to adapt to new ways of operating. It is through collaboration, knowledge

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · Photovoltaic glass is transparent solar panels designed to replace conventional glass in buildings and structures. These panels are capable of

C E R T I F I C A T E

Feb 18, 2021 · Mono-Crystalline Silicon Photovoltaic Module The product was tested on a voluntary basis and complies with the essential requirements. The certification mark shown

Potential environmental risk of solar cells: Current

Jun 15, 2020 · Photovoltaic (PV) technology such as solar cells and devices convert solar energy directly into electricity. Compared to fossil fuels, solar energy is considered a key form of

Standard and production of photovoltaic glass

2. Standard of photovoltaic glass sand The quality requirements of PV glass sand are mainly reflected in three aspects: chemical composition, particle size and

From PV to cement: harnessing glass waste for sustainable

Jan 21, 2025 · This review explores the potential of reusing glass waste from decommissioned photovoltaic panels in cementitious materials, highlighting improvements in durability,

Review of issues and opportunities for glass supply for photovoltaic

According to two standards for PV glass manufacturing in China, national (GB/T 30984.1-2015) 27 and industrial (T/CPIA 0028.1-2021), 28 the Fe 2 O 3 content of ultra-white patterned and float

A review of toxicity assessment procedures of solar photovoltaic

Feb 15, 2024 · The RCRA sets limits for eight metals, including a 5 mg/liter (mg/L) limit for lead, silver, arsenic and chromium, a 1 mg/L limit for cadmium and selenium, a 0.2 mg/L limit for

Products & Solutions

A positive impact on environment SunMax Premium – Arsenic- and antimony-free extra clear float glass for solar applications – Good for trouble-free recycling!

Glass Manufacturing

Art glass production still involves manual batch handling and glass blowing. Flat glass and container glass production has become increasingly automated. Potential exposures in glass

(PDF) Review of Issues and Opportunities for

Jan 1, 2025 · 11 iron sand is required for PV glass production, to make the glass highly transparent and reduce the absorption of

Role of NaCl on structural, optical and mechanical properties

May 1, 2025 · Karina et al. [17] studied the recycling of photovoltaic glass waste and used it as a substrate in photovoltaic applications. Glass substrate prepared from photovoltaic glass

European Glass-Glass Photovoltaic Modules Are

Sep 23, 2021 · Glass-glass PV modules (b) do not require an aluminum frame and therefore have a lower carbon footprint than PV modules with backsheet

Chinese PV Industry Brief: Solar glass capacity

Jul 19, 2022 · The Chinese government has revealed that the nation''s solar glass capacity has reached 64,000 metric tons per day, while State Grid Corp. of

Solar Photovoltaic Glass Market Size, Share

Jun 26, 2025 · Solar Photovoltaic Glass Market Analysis by Mordor Intelligence The solar photovoltaic glass market size reached 32.10 million tons in 2025

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

6 FAQs about [What is the arsenic content of photovoltaic glass exported ]

Can Photovoltaic Glass Waste be recycled?

Materials (Basel). 2023 Apr; 16 (7): 2848. Because of the increasing demand for photovoltaic energy and the generation of end-of-life photovoltaic waste forecast, the feasibility to produce glass substrates for photovoltaic application by recycling photovoltaic glass waste (PVWG) material was analyzed.

What is photovoltaic waste?

The total amount of photovoltaic waste generated globally reached 45 thousand tonnes in 2016, and is projected to increase to 60 million tonnes by 2050. This waste contains both valuable resources and hazardous substances. The recoverable valuables include aluminum, copper, and glass, which are already being recycled today.

Does solar glass contain antimony?

However, the composition of solar glass varies, especially concerning antimony (Sb) content, depending on the production method. Antimony is used to enhance the performance of patterned solar glass but introduces environmental and health concerns, complicating recycling efforts.

What are the most toxic materials in PV module structure?

Less commonly investigated but toxic materials also include zinc, copper, and nickel. As the distribution of key materials within PV module structure is inhomogeneous, the sampling method must account for the material spatial distribution.

Can transparent conductive oxide be used in thin-film photovoltaic glass windows?

The purpose of this work was the production of glass substrates using PVWG as main material, as well as other residues such as dolomite and quartz sand, and applying a transparent conductive oxide (TCO) in order to evaluate their properties for their possible application in thin-film photovoltaic glass windows. 2. Materials and Methods

Are photovoltaic modules causing end-of-life waste in Europe?

Following an active analytic and collaborative process during spring and summer, the second ESIA recommendation paper has just been released. The rapid increase in end-of-life waste from photovoltaic (PV) modules in Europe is a significant challenge.

Industry Information

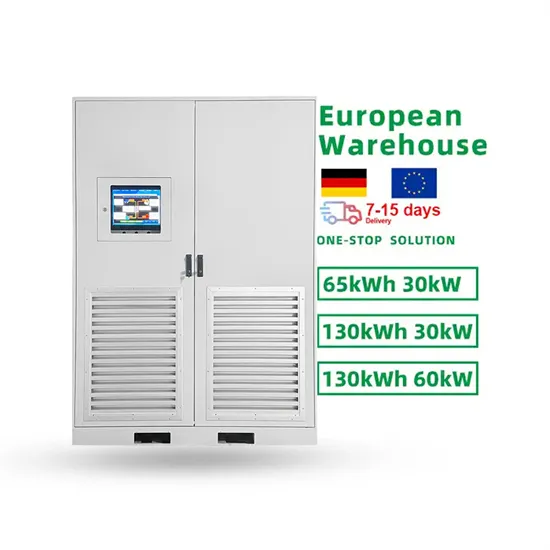

- Norway s new energy storage power station

- Lome Capacitive Energy Storage Equipment Company

- Colombia Mobile s 5G base station power supply

- How much is the price of supercapacitors in Africa

- Circuit breaker amps for sale in Brazil

- Can Dushanbe s energy storage power supply be used

- Does Suriname currently have any energy storage projects

- Bifacial Micro Inverter

- Overall planning of energy storage power station project

- Communication base station customized solar energy sales

- Photovoltaic Energy Storage Wholesale

- Lightweight portable backup power supply

- Hanoi photovoltaic energy storage manufacturer number

- Lithium iron phosphate energy storage power supply

- Superconducting Magnetic Energy Storage Company

- Which components of a 5g base station consume power

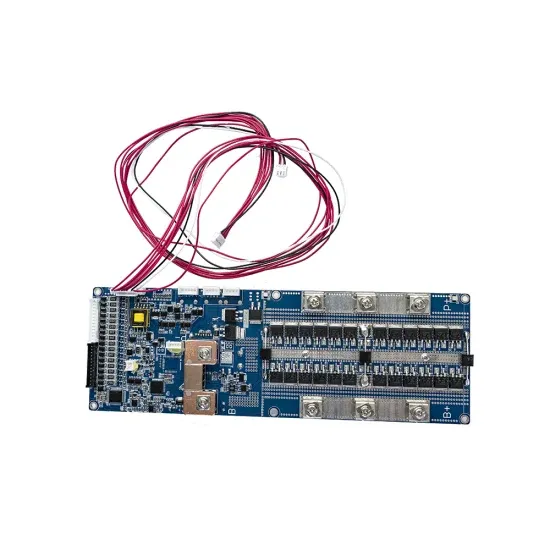

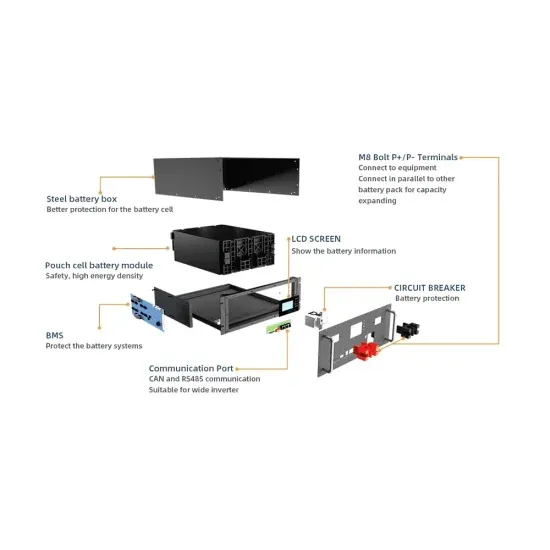

- BMS Battery Safety

- New Energy Storage Quote

- Huawei Bangui Energy Storage Battery Production Area

- Cairo communication base station flywheel energy storage maintenance

- Chad 110kw high quality inverter manufacturer

- Clean photovoltaic energy at Hanoi power plant

- Black Mountain Power Energy Storage Supplier

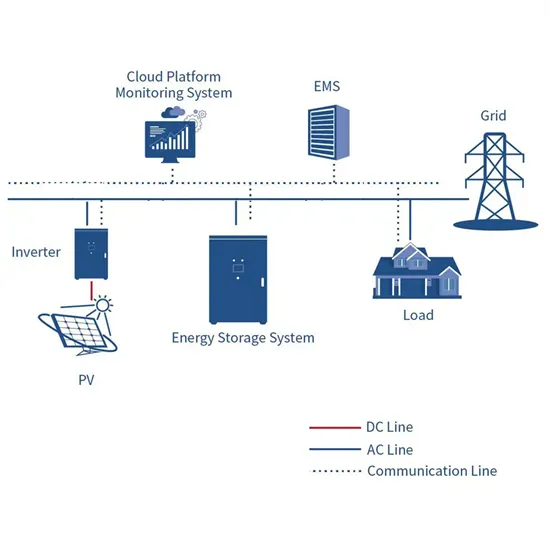

Commercial & Industrial Solar Storage Market Growth

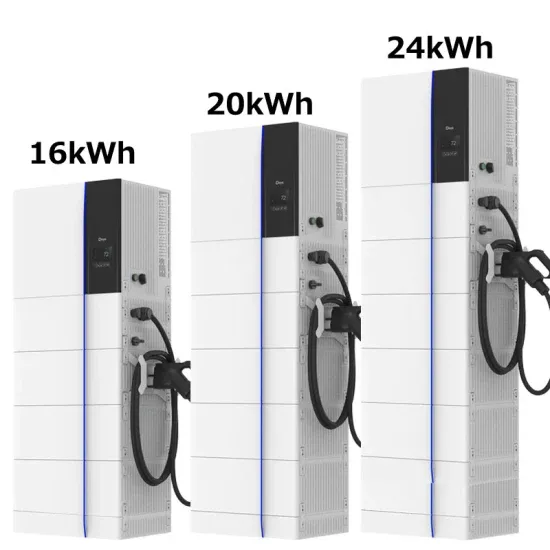

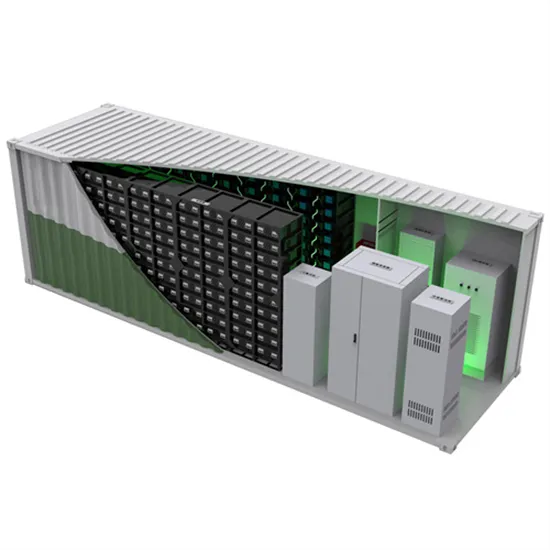

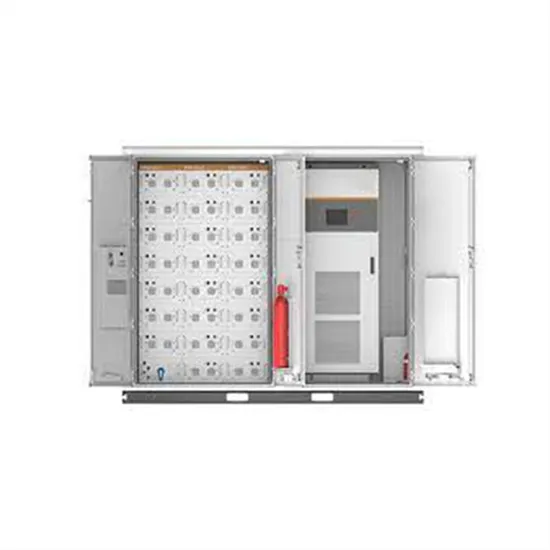

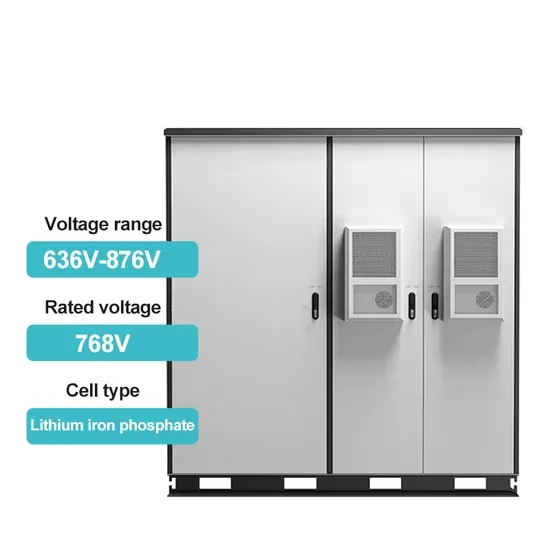

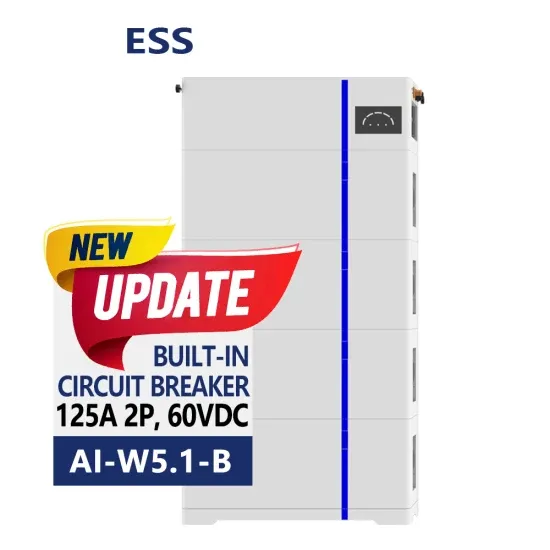

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

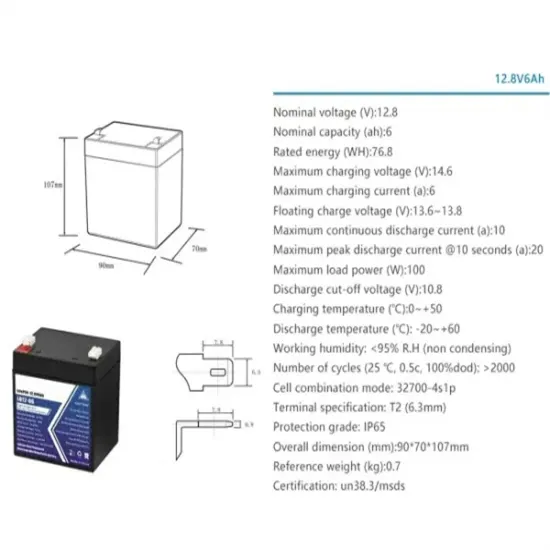

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.