All Things You Need to Know about Lithium

These are so-called lithium battery series, parallel and series-parallel connections. That is also a simple theory of forming a lithium battery pack.

How to connect multiple 48V lithium battery packs?

When considering connecting multiple 48V lithium battery packs, we have two primary connection methods: series and parallel. Each method has its own advantages and considerations. In a

Series and Parallel, which is the first when

Aug 27, 2024 · Series and Parallel, which is the first when assembling lithium battery packs? In the design of the battery modules, whether to connect them

What Is The Difference Between Batteries In Parallel Vs Series?

What safety risks arise in each configuration? Series risks include overvoltage damage to low-rated devices, while parallel systems risk thermal runaway from current imbalances. For

Cells in Series and Parallel – NPP POWER

Jun 1, 2023 · The process of assembling lithium cells into a group is called PACK, which can be a single cell or cells in series and parallel lithium battery pack,

48V Lithium Battery Pack: Versatile Energy for Solar, EV,

Jul 23, 2025 · A 48V lithium battery pack is a pre-assembled collection of lithium cells connected in series and/or parallel to produce a nominal 48 volts of direct current. Most packs use a 16

Lithium Battery Series and Parallel Connection

Battery pack Voltage of series connection: the voltage is added when the battery cells are connected in series. For example, 3.7V single cells can be

Examples of Battery Pack Configurations

May 25, 2025 · Examples of battery pack configurations, going up in total energy content down the page. Sort of as we have separated out the packs that are

Battery Series vs Parallel Explained

Jul 10, 2025 · For instance, two sets of four series-connected batteries wired in parallel would deliver 48V 400Ah—ideal for powering homes during outages. Pro Tip: Always use identical

Ultimate Guide of LiFePO4 Lithium Batteries in

Parallel connection of LiFePO4 batteries refers to connecting multiple cells together by linking the positive terminals and negative terminals to increase

How to connect 12V batteries to get 48V?

May 30, 2025 · Connecting 12V batteries to achieve 48V requires wiring four identical 12V units in series. This configuration adds voltages while maintaining the same ampere-hour (Ah)

How To Connect Multiple 48V Batteries In Series

Jun 27, 2024 · Multiple 48V Lithium batteries are quickly connected in parallel or series, to offer additional power for various applications. They can be adapted

Everything About Lithium Battery Series

May 21, 2025 · The series and parallel connection of lithium batteries is a key technology to increase voltage and capacity, but it also contains safety risks.

Lithium Battery Series and Parallel Connection

Take a 48V 20Ah lithium battery pack as an example: Assuming that the single cell specification used is 18650 3.7V 2000mAh. Number of parallel cells:

Parallel Battery Packs

Oct 15, 2024 · Parallel then Series or Series then Parallel How should you connect battery cells together: Parallel then Series or Series then Parallel?

Parallel vs. Series Wiring: Which Boosts 48V LiFePO4 Battery

Apr 22, 2025 · Choosing between parallel and series wiring for 48V LiFePO4 systems impacts cost, safety, and scalability. We break down the engineering trade-offs with real data. When to

Series Vs. Parallel Battery | How To Choose?

Dec 26, 2023 · For example, for the Delong 12V 100Ah lithium iron phosphate battery, currently up to 4 batteries can be connected in series to obtain a 48V

How to Wire Batteries in Parallel or Series

Dec 7, 2018 · For example, if connecting two of our 12V 10Ah Dakota Lithium batteries in series, what you''ll get is a doubling of voltage or a 24V 10Ah

Parallel 2 48V lifepo4 batteries advice

Apr 11, 2021 · Ummm, colour me confused. 48V Pack requires 16 LFP Cells @ 3.2V, with a 16S BMS. 12V required 4 LFP cells in a 4S Config with a 4S

Series vs Parallel Battery Wiring: Key Differences,

Apr 8, 2025 · When using multiple batteries in a project, you have two primary wiring configurations—series and parallel. Each has distinct advantages

How to Connect 6 Batteries to 48V: Series vs. Parallel

Aug 14, 2024 · Redway Power offers OEM lithium battery packs designed for easy series and parallel wiring with integrated Battery Management Systems (BMS). Their batteries ensure

Energy Storage Battery 48V 100Ah Lithium

4 days ago · The 48v 100Ah LiFePO4 battery pack is compact, easy to install, free of maintenance and is used as the building block of energy storage

How To Wire Lithium Batteries In Parallel

Aug 9, 2022 · In this article, we will explain why you would want to wire lithium-ion batteries in parallel, how you wire them in series and how to charge battery

Can You Mix Different Capacity Lithium

Jun 20, 2023 · Schematic for multiple lithium batteries in parallel Here is a diagram for multiple lithium batteries in parallel. You can add individual battery

Series, Parallel, and Series-Parallel Connections of Batteries

The number of batteries you can wire in series, parallel, or series-parallel depends on the specific application and the capabilities of the battery bank you are building. For details, refer to the

Series and Parallel

When assembling large battery packs it is necessary to connect cells in series and parallel. Increasing the working voltage and capacity.

Wiring Batteries in Series Vs. Parallel | Battle

Jul 29, 2025 · The main difference between wiring batteries in series vs. parallel is the impact on the battery system''s output voltage and capacity.

How to Choose the Right Ah for 48V Li-ion Battery Pack?

Apr 27, 2025 · To create a 48V pack, you need about 13 or 14 cells connected in series (13 × 3.7V ≈ 48V). A high-capacity pack might have several strings of 13 cells connected in parallel to

Batteries in Parallel vs Series, All You Need to

Jan 20, 2024 · Series batteries require monitoring for voltage sag across individual cells, while parallel systems need attention to current sharing and

Connecting Lithium Batteries in Parallel and

Lithium battery pack technique refers to the processing, assembly and packaging of lithium battery pack. The process of assembling lithium cells together is

How to Connect Multiple 48V Lithium Batteries in Parallel

Sep 29, 2024 · Connecting multiple 48V lithium batteries in parallel can significantly enhance your energy storage capacity while maintaining the same voltage. Here''s a comprehensive step-by

How to Choose the Right Ah for 48V Li-ion Battery Pack?

Apr 27, 2025 · To create a 48V pack, you need about 13 or 14 cells connected in series (13 × 3.7V ≈ 48V). Series connection = Adds voltage Parallel connection = Adds capacity (Ah) A high

How to Calculate the Number of Lithium

Lithium Battery PACK Lithium battery PACK refers to the processing, assembly and packaging of lithium battery packs.The process of assembling lithium

6 FAQs about [48v lithium battery pack parallel series]

Are series and parallel connection of lithium batteries safe?

The series and parallel connection of lithium batteries is a key technology to increase voltage and capacity, but it also contains safety risks. This article will analyze in detail the principles, methods and precautions of series and parallel connection of lithium batteries to help you avoid potential risks and build a battery system correctly.

What is lithium battery parallel connection?

Lithium battery parallel connection is to connect the positive poles of multiple batteries together, and the negative poles together, so that the total capacity can be increased while keeping the voltage unchanged.

How to charge parallel lithium battery packs?

Specific principles must be followed when charging parallel lithium battery packs: Use a matching charger: The voltage must be suitable for the nominal voltage of the individual batteries. The current setting is reasonable: usually 0.2-0.5C of the total capacity after parallel connection.

What is parallel connection of LiFePO4 batteries?

Parallel connection is ideal for applications that require high capacity, such as backup power supplies for buildings and off-grid solar power systems. It allows for efficient energy storage and ensures even distribution of charge and discharge within the battery pack. Parallel connection of LiFePO4 batteries also has some disadvantages, including:

What is the difference between LiFePO4 and 12V batteries?

For instance, if four 12V batteries are connected in series, the output voltage of the battery pack will be 48V. In contrast, parallel connection of LiFePO4 batteries increases the overall capacity of the battery pack, but the voltage output remains the same as that of an individual cell or battery.

How many lithium batteries can be connected in series?

For instance, LiTime allows for a maximum of four 12V lithium batteries to be connected in series, resulting in a 48-volt system. It's always important to consult the battery manufacturer to ensure that you stay within their recommended limits for series connections.

Industry Information

- Norway s new energy storage power station

- Lome Capacitive Energy Storage Equipment Company

- Colombia Mobile s 5G base station power supply

- How much is the price of supercapacitors in Africa

- Circuit breaker amps for sale in Brazil

- Can Dushanbe s energy storage power supply be used

- Does Suriname currently have any energy storage projects

- Bifacial Micro Inverter

- Overall planning of energy storage power station project

- Communication base station customized solar energy sales

- Photovoltaic Energy Storage Wholesale

- Lightweight portable backup power supply

- Hanoi photovoltaic energy storage manufacturer number

- Lithium iron phosphate energy storage power supply

- Superconducting Magnetic Energy Storage Company

- Which components of a 5g base station consume power

- BMS Battery Safety

- New Energy Storage Quote

- Huawei Bangui Energy Storage Battery Production Area

- Cairo communication base station flywheel energy storage maintenance

- Chad 110kw high quality inverter manufacturer

- Clean photovoltaic energy at Hanoi power plant

- Black Mountain Power Energy Storage Supplier

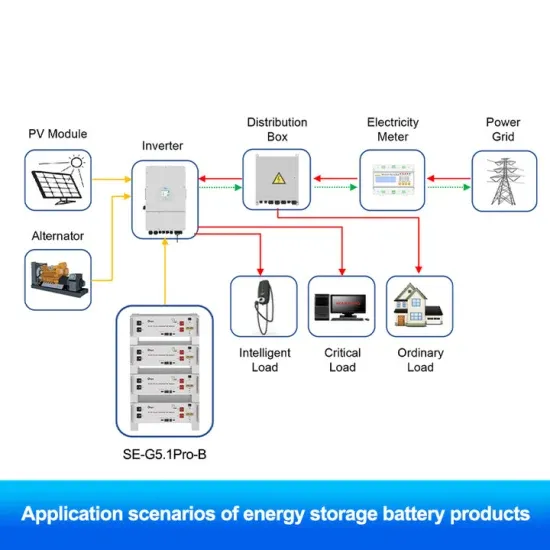

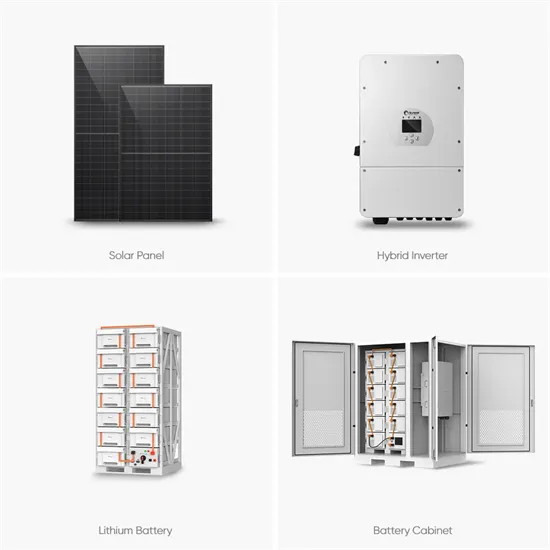

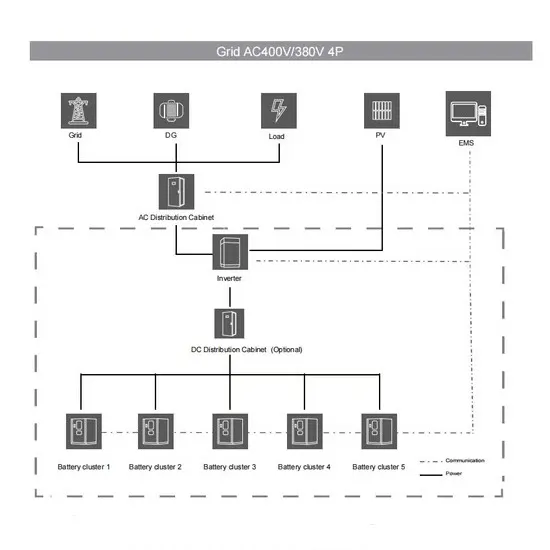

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.