High performance alkaline-acid direct glycerol fuel cells for portable

Jan 13, 2020 · Alkaline-acid direct glycerol fuel cells (AA-DGFC) were fabricated and primarily proven to be used as portable power generating devices. Pt/C catalyst was used as

DIY Portable Power Supply : 7 Steps

DIY Portable Power Supply: A power supply with battery charger, Booster circuit, Minimal design, Easy to use I/O and with different voltage output modes. Let''s

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · The battery pack assembly process is a cornerstone of modern manufacturing, essential for producing high-performance battery packs used

Modules Accelerate the Power Design Process

Jun 29, 2022 · These changes in power requirements have devel-oped over the same period of time, making many design practices obsolete. In the future, these trends are set to continue or

PD Portable Bench Power Supply

Jun 1, 2025 · The PD Adjustable DC Power Supply is a compact, USB-C-powered device designed to provide adjustable voltage output like a traditional

Portable Power Supply PCBA Manufacturing: Process and

Mar 22, 2025 · What is a Portable Power Supply PCBA? A Portable Power Supply PCBA (Printed Circuit Board Assembly) is the core component of battery-powered electronic devices,

Portable Power and Control Electronics

Jun 13, 2025 · The 990-ELE1 features a wide variety of electrical components and circuits, including: AC and DC power supplies, ΔV poten- ometer, thermocouples, resis ve temperature

Power Bank Manufacturing Process: How We

Ready to know about the making process of power banks? Awesome! This post contains our regular manufacturing process for power banks, including the

Top power supply PCB assembly guidelines! –

May 20, 2025 · Power supply PCB assembly is a critical process that requires careful planning, design considerations, and adherence to best practices. By

The Design And Manufacturing Process Of Portable Power

Jun 13, 2025 · Once the components are sourced, the assembly begins. This process usually takes place in clean, dust-free environments to avoid any contamination that could affect the

Portable Power Supply Pt III: Testing — Ryan

Jan 31, 2022 · The project so far In my first blog for this project, I described the concept and design of a revised variant of an open source power supply

How Power Supplies Work: Switching vs. Linear

FSPCBA takes an in-depth look at how power supplies work: switching power supply vs linear power supply. We analyse their operating principles and

PSU Assembly Guide: Step-by-Step Instructions

AI Tools STEP BY STEP POWER SUPPY UNIT (PSU) ASSEMB L Y STEP 1: GA THER YOUR MA TERIALS Before you start assembling your power supply

Production Process of Portable Power Plants

Feb 23, 2024 · In this article, we will explore the production process of portable power plants, from design and component selection to assembly and testing. 1. Design and Planning. The

Design and Manufacturing Process of Portable Lifepo4 Power

Design and Manufacturing Process of Portable Lifepo4 Power Stations With the growing demand for energy diversity and power flexibility, portable lifepo4 power stations have become critical

How Are Portable Power Stations Manufactured

Oct 22, 2024 · As portable power stations continue to gain popularity for their convenience and versatility, understanding their manufacturing process can

Power Station Manufacturer, Portable Power Station, Solar

From LED emergency power supply to portable power station and solar panels, with the support of many customers, WeledPower has steadily developed to 10, 000+ square meters, 400+

Power Assemblies

Direct''s power assemblies are industrial grade cable systems used within environments requiring permanent or temporary power supply. We combine

DIY Portable Power Supply

Sep 9, 2024 · DIY Portable Power Supply A power supply with battery charger, Booster circuit, Minimal design, Easy to use I/O and with different voltage

Production Process of Portable Power Plants

Feb 23, 2024 · ```html Portable power plants play a crucial role in providing electricity in remote areas and during emergencies. Production of these power stations involves a complex

Production Process of Portable Power Plants

The production process of portable power plants begins with meticulous design and planning. Engineers and designers work together to create detailed plans that outline the specifications,

Building 12V Battery Packs with 18650 Cells: A Guide

Jun 8, 2024 · Portable power supplies for camping Conclusion Building a 12V battery pack with 18650 cells is an enriching project that provides practical skills and knowledge about battery

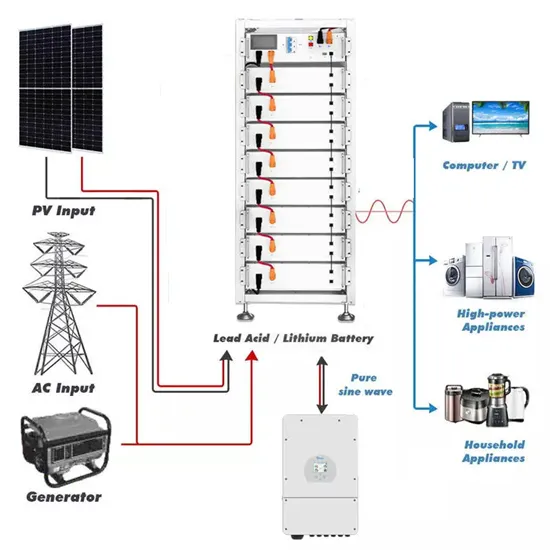

Design of a Portable AC/DC Power Bank Using 32650

Jul 14, 2022 · The building process of a small-scale, cost-effective portable solar power supply. The end product comes with a solar panel to capture and convert solar energy to electrical

DIY Portable Power Supply

Sep 13, 2024 · A power supply with battery charger, Booster circuit, Minimal design, Easy to use I/O and with different voltage output modes. Let''s build

Design and Manufacturing Process of Portable Lifepo4

Design and Manufacturing Process of Portable Lifepo4 Power Stations With the growing demand for energy diversity and power flexibility, portable lifepo4 power stations have become critical

How to Make a 12V Portable Power Supply

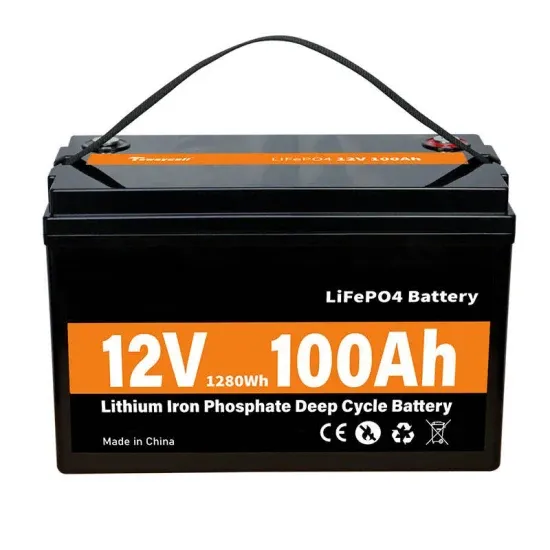

Jul 1, 2024 · Today, We will share the process of making a 12V portable power supply using 18650 ternary lithium batteries, each with a capacity of 2500mAh.

Design and Manufacturing Process of Portable Lifepo4 Power

With the growing demand for energy diversity and power flexibility, portable lifepo4 power stations have become critical china portable power station suppliers equipment for emergency rescue,

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

PCB Assembly for Power Supply Applications

Dec 16, 2022 · PCB Assembly for Power Supply Applications PCB assembly for power supplies involves mounting and soldering various components onto a

The Comprehensive Guide to Power Bank

Apr 10, 2024 · Discover the intricate journey of power bank manufacturing in our comprehensive guide. From rigorous quality checks to the final packaging,

The 7 Best Portable Power Stations of 2025

Apr 10, 2025 · Bring big backup power with you with these expert-recommended portable power stations, which can store enough power to charge electronics,

Industry Information

- Stockholm Free Outdoor Communication Power Supply BESS

- New Energy Battery Cabinet Storage Pool

- China-Africa Energy Storage Peak Shaving Price

- Can the outdoor power supply be increased in power

- High quality China bolt on circuit breaker for sale

- Yaounde new energy base station subsidies

- Flywheel energy storage plus disc generator

- Luxembourgonn outdoor power supply

- What to use for outdoor power fast charging

- Columbia Energy Storage Project

- Solar Energy Storage Direct Flexibility

- Ottawa photovoltaic glass manufacturer

- North Korea solar power generation and energy storage manufacturers

- Energy Storage Integrated Systems Company

- Can photovoltaic energy storage battery packs be connected in parallel

- How much does it cost to install a water pump with solar energy

- Photovoltaic power generation rural rooftop solar panels

- Solar power solutions factory in Sweden

- Wholesale 300wh power station in Norway

- Terrace home solar power generation system

- Finished distribution cabinet container base station

- Solar Panel On-site Energy Design Ideas

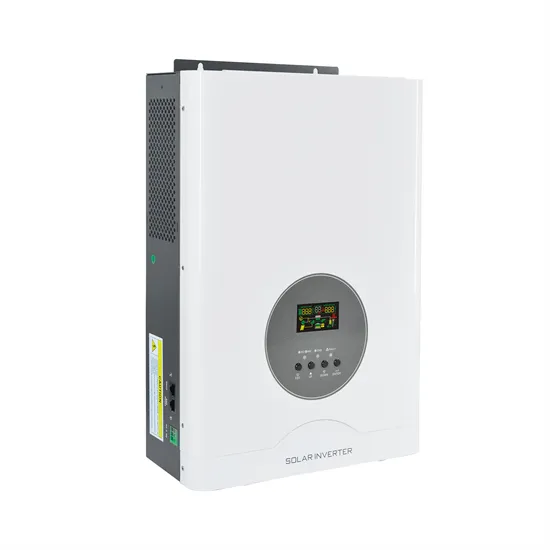

- Seoul three phase inverter sales

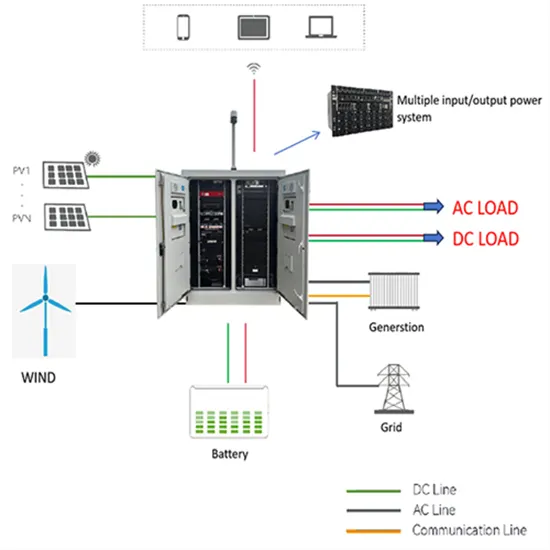

Commercial & Industrial Solar Storage Market Growth

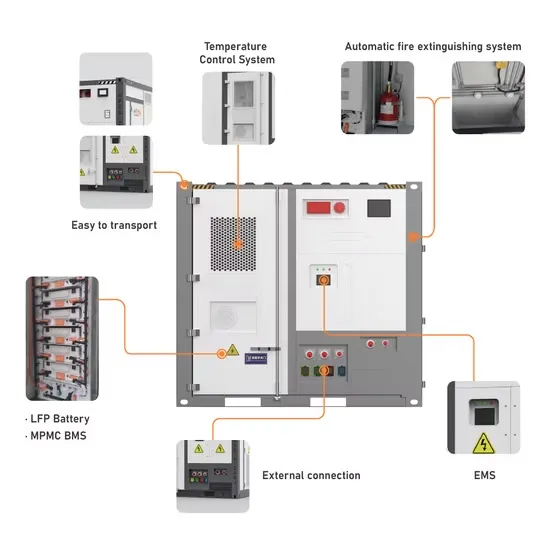

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.