CPS-i Battery Energy Storage System

Dec 16, 2021 · Reduce complexity and speed deployment of utility-scale energy storage This fully integrated storage system combines our UL-1741 SA certified CPS energy storage inverters

A Study Photovoltaic Inverter System with MPPT and Battery Charge

Apr 22, 2025 · This paper addresses the standalone application-based Solar PV inverter system with MPPT algorithm enabled and battery charging using MATLAB (Simulink) to improve its

Designing a high voltage DC-link capacitor

Apr 23, 2024 · A straightforward approach to designing an efficient, active pre-charge circuit using a spreadsheet calculator.

DC bus pre-charging techniques

Mar 25, 2021 · In voltage source converters, pre-charging the inverter DC bus is required before connecting it to external voltage sources, so that to avoid

Application and Selection of Pre-charge Resistor and Energy Storage

General charging resistance selection: the maximum value is best not to exceed 300 Ω, the minimum value is best greater than or equal to 10 Ω, high-power inverter selection charging

Energy storage high voltage box pre-charging resistor

Oct 22, 2020 · The resistance of the precharge resistor is chosen based on the capacity of the load and the desired precharge time. The precharge surge current reaches 1/e of its initial

What is a Precharge Resistor and Why Is It

May 23, 2025 · Simply put, it''s a specialised power resistor that acts like a traffic controller when you power up a circuit. When you flip that switch, capacitors in

BATTERY ENERGY STORAGE SYSTEMS (BESS)

Jul 8, 2024 · The PCS also controls the charging and discharging process of the battery and allows for the large-scale utilization of renewable energy sources, energy storage, and

What is pre-charging and how does it work?

These loads will reduce the pre-charge current flowing to the inverter input capacitor, and they may even prevent full pre-charge. A pre-charge time of 5

Pre-Charge Resistor

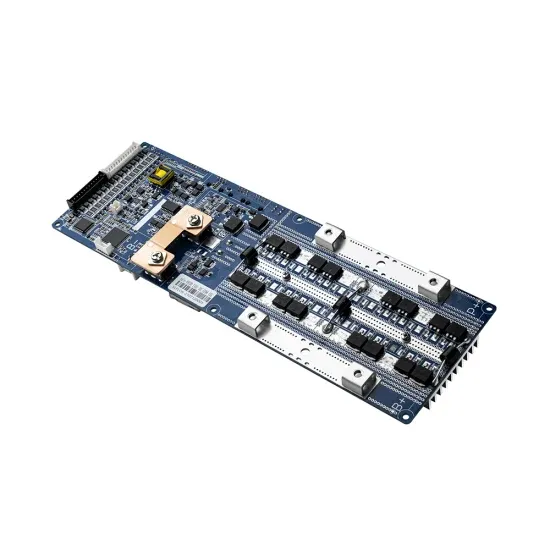

Dec 12, 2022 · Therefore, when we closed the contactors on the battery pack we do this in three steps: A simplified schematic shows the basic principle. The

energy storage pre-charge circuit

DC Pre-Charge Units for PV & Battery Inverters | Dynapower Without the use of a pre-charge unit, these inrush currents can damage the batteries, the capacitors and IGBTs. Essentially, a pre

Analysis of inverter fault caused by charging resistance and energy

The medium and small power general purpose frequency converter is usually voltage-type frequency converter, which adopts ac-dc-ac Operation Mode. When the inverter just on power,

DOE ESHB Chapter 13 Power Conversion Systems

Sep 3, 2021 · Abstract Power electronic conversion systems are used to interface most energy storage resources with utility grids. While specific power conversion requirements vary

Why Pre-Charge Circuits are Necessary in High-Voltage

Dec 23, 2023 · Pre-charge In a high voltage system, a typical block diagram may consist of two high current contactors with a separate pre-charge contactor, and a DC link capacitor in

Pre-Charge Circuits in High-Voltage Systems

Jun 1, 2023 · In a high voltage system, a typical block diagram may consist of two high current contactors with a separate pre-charge contactor, and a DC link

Precharge Circuits, How to Protect High Voltage

Jun 30, 2022 · The pre-charge control circuit is composed by a relay (precharge contactor) and a resistor. These two components are wired in and installed on

CPS Gen5: Utility Scale Energy Storage Inverters

Nov 30, 2022 · Dynapower''s CPS-1250 and CPS-2500 energy storage inverters offer industry-leading power density and configuration flexibility.

Study on pre-charging process and pre-insertion

Jan 21, 2019 · Here, the uncontrolled rectification pre-charging characteristics of the VSC-HVDC system with different modular multilevel converter (MMC)

Pre-Charge inverter

Nov 16, 2020 · Hello folks. Am Currently building a system, and am wondering about the pre-charge-issue. I have a BMS (SimpBMS), which will (after checking battery parameters) trigger

Energy Storage Inductor Resistance: The Silent Game Changer

May 30, 2022 · When it comes to energy storage inductor resistance, these components can be real drama queens. Let''s cut through the technical jargon: inductor resistance isn''t just about

Precharge Calculator | Sensata Technologies

3 days ago · The following calculator can aid in the design of a precharge circuit for an electric vehicle. It will compute the precharge resistance required to

Inverter pre-charge resistor size?

Apr 27, 2021 · Most inverters will fire up into standby mode with the microcontroller and display requiring less than 500 mA''s at minimum inverter battery voltage. Any series dropping

Energy Storage Inverter Pre-Charging: The Unsung Hero of

May 30, 2024 · Why Your Energy Storage System Needs a "Warm-Up" Session Imagine plugging a frozen smartphone into a charger - it might work, but you''re risking a battery meltdown.

POWERTRAIN PRE

Apr 16, 2024 · Electrically powered vehicles have various electrical energy sources. In addition to the HV-drive battery, capacitors are in-stalled in various modules such as drive inverter, DC

Pre-Charging Resistance: A Critical Component

Jan 3, 2025 · Understanding the Role of Pre-Charging Resistance In the realm of energy storage systems, pre-charging resistance plays a vital role in ensuring

A Novel Way of Using Power Modules to

Aug 21, 2024 · Using the same components that already exist in legacy systems (the DC-DC converter and DC-DC regulator), designers can both pre-charge

SoC–Based Inverter Control Strategy for Grid-Connected Battery Energy

Jan 23, 2025 · The successful integration of battery energy storage systems (BESSs) is crucial for enhancing the resilience and performance of microgrids (MGs) and power systems. This study

A Novel Way of Using Power Modules to Eliminate Electric

Aug 21, 2024 · Using the same components that already exist in legacy systems (the DC-DC converter and DC-DC regulator), designers can both pre-charge and power the low-voltage

(PDF) Comprehensive Analysis of Pre-Charge

Dec 25, 2019 · This study presents a comprehensive analysis off pre-charge sequences between conventional and semiconductor switchgear to be used in

How to Pre-Charge Capacitive Circuits

Dec 12, 2021 · Learn how to pre-charge capacitive circuits to prevent inrush currents. It''s critical in any capacitive circuit with high voltage.

Battery charging & power conversion | Victron

Fast-charge battery banks or power any AC/DC load worry-free. From RVs to marine and industrial uses, our products cover every charging and conversion

QS-ESB-A

May 22, 2025 · When a energy storage system is switched on, the DC link (e.g. in the inverter) is usually uncharged. Without a pre-charging path, this capacitor would suddenly charge up via

how to calculate precharge resistor

Mar 12, 2021 · The precharge resistor needs only to withstand load for a few seconds - it''s limiting charging current for the DC capacitor. The smaller the resistance/higher the current, the

10-kW, GaN-Based Single-Phase String Inverter With

Aug 29, 2024 · Description This reference design provides an overview into the implementation of a GaN-based single-phase string inverter with bidirectional power conversion system for

A closer look at the DC Link

Nov 10, 2020 · The term DC link has traditionally referred to the junction between two power conversion stages where an energy storage element (almost

DC Pre-Charge Units for PV & Battery Inverters | Dynapower

Sep 9, 2019 · In most PV applications, pre-charge of the Inverter DC bus capacitance is not required due to the I-V characteristic of the PV cell. The inherent current limit of the PV array

6 FAQs about [Energy storage inverter DC pre-charge resistance]

What happens when DC voltage is applied to an energy storage inverter?

When DC voltage is applied to the input of an energy storage inverter, large inrush currents will occur as the DC bus capacitance will initially appear as a short. Without the use of a pre-charge unit, these inrush currents can damage the batteries, the capacitors and IGBTs.

What is a precharge resistor?

A precharge resistor is your system’s first line of defence against potentially destructive inrush currents. But what exactly is it? Simply put, it’s a specialised power resistor that acts like a traffic controller when you power up a circuit. When you flip that switch, capacitors in your system are eager to charge—too eager, in fact.

Why do solar inverters and wind power converters have precharge resistors?

Solar inverters and wind power converters incorporate precharge resistors to protect expensive power electronics from the stresses of grid connection and disconnection.

What is a PEC precharge resistor?

PEC precharge resistors are built with decades of problem-solving experience and technical knowledge. They provide the reliability and performance necessary for modern high-voltage applications while protecting valuable system components. Required fields are marked *

Why do batteries need a DC pre-charge unit?

Batteries have extremely high short circuit capacities. This results in them being able to provide an extremely high peak inrush current to the inverter DC bus. This inrush current needs to be mitigated with the use of DC pre-charge assemblies. Dynapower’s CPS and DPS product lines come with integrated pre-charge units.

Does a PV battery need a pre-charge?

In most PV applications, pre-charge of the Inverter DC bus capacitance is not required due to the I-V characteristic of the PV cell. The inherent current limit of the PV array will limit the current inrush on the inverter bus to acceptable levels. Batteries have extremely high short circuit capacities.

Industry Information

- Vietnam energy storage cabinet manufacturer wholesale

- Basic electricity price of energy storage power station

- Somaliland 5g base station electrical cabinet

- The maximum number of kilowatts of solar lights

- Hot sale China high tension switchgear Factory

- How much does container energy storage cost in Djibouti

- Latest sales of outdoor energy storage power supply

- Botswana Distributed Energy Storage Quote

- German wind power energy storage system manufacturer

- Lima batteries and energy storage cabinet batteries

- Solar thermal power generation energy storage capacity

- 36v DC can use 12v inverter

- How many hours does it take for a UPS uninterruptible power supply to be qualified

- Energy storage station and photovoltaic station

- Grid-connected NIMBY effect of government communication base station inverter

- Brasilia 15GWh Energy Storage Battery Project

- Photovoltaic panel wind and solar package price

- Electricity introduction budget for communication base stations

- Small uninterruptible power supply in Venezuela

- Distributed energy storage system suppliers

- Togo s new photovoltaic panel prices

- Arc flash switchgear in China in Peru

- Djibouti safe energy storage power supply service

Commercial & Industrial Solar Storage Market Growth

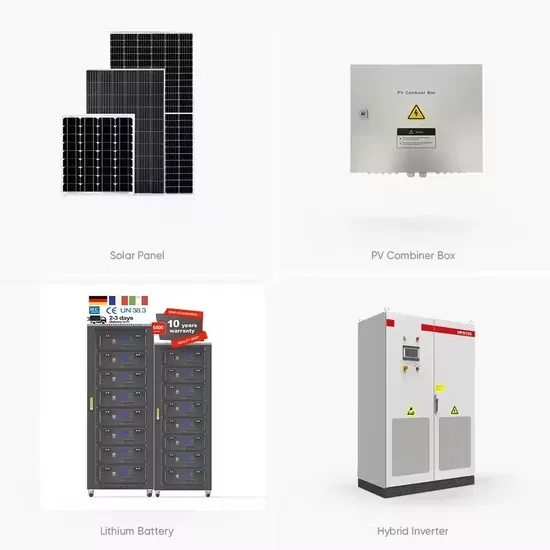

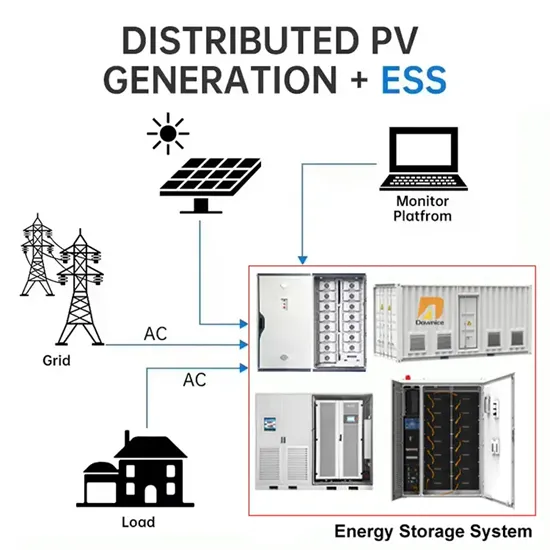

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.