Air-cooled C&I BESS Energy Storage Cabinet | AZE

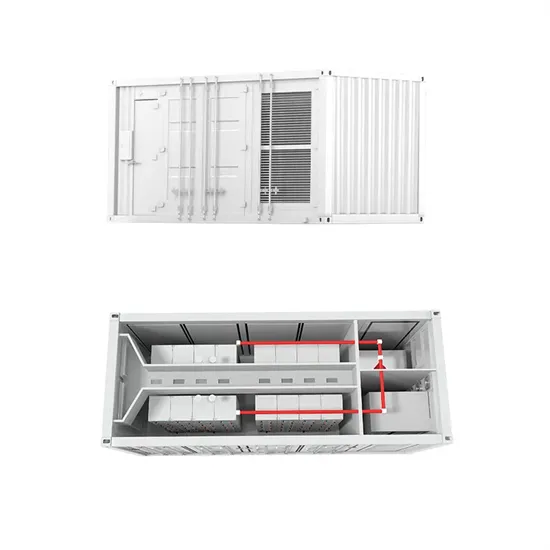

AZE''s Our air-cooled C&I BESS Energy Storage Cabinet is the perfect solution for your business. With advanced air-cooling technology, scalable design, and smart energy management, our

Performance investigation of thermal

Jan 1, 2023 · In this article, to facilitate Li-ion battery in a favorable thermal state, a battery thermal management (BTM) design integrating phase change

Immersion cooling technology development status of

At the same time, the utilization of waste heat in the data center immersion cooling system is discussed, providing readers with extensive and detailed background knowledge of data

Research on air‐cooled thermal management of energy storage lithium battery

May 15, 2023 · In order to explore the cooling performance of air-cooled thermal management of energy storage lithium batteries, a microscopic experimental bench was built based on the

Research papers

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

Air-Cooled Thermal Management for EV Battery Packs

Jul 30, 2025 · Discover innovations in air-cooled EV battery pack thermal management, enhancing efficiency, performance, and battery lifespan.

What are the cooling technologies for domestic battery

What are the cooling technologies for domestic battery cabinets Air cooling for cabinets over 20kW significantly reduces the effect of chip-level liquid cooling and immersion. using

Comparison of different cooling methods for lithium ion battery

Feb 5, 2016 · Choosing a proper cooling method for a lithium-ion (Li-ion) battery pack for electric drive vehicles (EDVs) and making an optimal cooling control stra

A Review of Different Types of Battery Cooling Systems

May 31, 2023 · This paper reviews different types of cooling systems used in lithium-ion batteries, including air cooling, liquid cooling, phase change material (PCM), heat pipe, thermo-electric

An optimization study on the performance of air-cooling

Jul 1, 2025 · In this study, a novel thermoelectric coupling model is used to numerically simulate the heat generation process of energy storage battery packs. Then, the impact of airflow

Air cooling and heat dissipation performance of multi-layer battery

A simulation analysis was conducted on the air cooling and heat dissipation performance of a single-layer battery cabinet. This is based on the fact that each layer of the battery cabinet has

Application of Refrigerant Cooling in a Battery

Jun 5, 2024 · Battery thermal management (BTM) is crucial for the lifespan and safety of batteries. Refrigerant cooling is a novel cooling technique that is

(PDF) Numerical Simulation and Optimal Design of Air Cooling

Jan 1, 2022 · Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence

Structure optimization of air cooling battery thermal

Mar 1, 2023 · Air cooling is a common and valid method to improve the heat distribution of battery thermal management system (BTMS). To further improve the heat dis

Research on the heat dissipation performance of battery pack

Oct 15, 2013 · This paper selects the forced air cooling of battery pack as the study object (the battery pack has a total of 48 batteries, and includes 4 battery modules with 2 parallels and 6

Optimal Structure Design and Temperature Control Strategy of Air

May 11, 2025 · The battery spacing and positioning are optimized based on cooling and heating conditions to determine the optimal heat dissipation configuration. The results reveal that

EV Battery Cooling System

Currently, RIGID Technology micro-cooling systems provide the following cooling approaches for domestic and foreign electric vehicle battery packs: Air

(PDF) Numerical Simulation and Optimal Design of Air Cooling

Jan 1, 2022 · The air cooling effect of battery cabin was improved by adding guide plate. There is better consistency between the modules and the modules can operate at more appropriate

Air Cooling Concepts for Li-Ion Battery Pack in

Jul 9, 2017 · Computational Fluid Dynamics (CFD) modeling is used to study different cooling architectures for the next generation (Gen-2) EREV Li-Ion

A review of air-cooling battery thermal management systems for electric

Jul 31, 2021 · It is found that with the help of advanced computational numerical simulations and sophisticated experiments, the air-cooling efficiency is greatly improved by introducing new

Analysis of Influencing Factors of Battery Cabinet Heat

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

Liquid Cooling: Efficiency in Battery Storage

The adoption of the Liquid Cooling Battery Cabinet is a pivotal step towards creating safer, more durable, and more efficient energy infrastructure. By ensuring batteries operate within their

Battery Energy Storage Systems: Liquid Cooling

Jul 3, 2025 · Compared to air cooling, liquid systems are more energy-efficient because they require less power to achieve the same cooling effect. This

Experimental and numerical investigation on thermal

Dec 5, 2015 · Then, the study focuses on the investigation of the performance of a passive air cooling system utilizing natural convection without moving parts inside the battery cabinet is

Numerical Simulation and Optimal Design of Air Cooling

Jan 1, 2022 · This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling. Firstly, a simulation model is established according to

(PDF) A Review of Advanced Cooling Strategies

Jun 28, 2023 · Research studies on phase change material cooling and direct liquid cooling for battery thermal management are comprehensively reviewed

What is a cabinet cooling system? Types, benefits, and how

4 days ago · A cabinet cooling system protects sensitive equipment from overheating. Learn about types of cooling systems for enclosures, key selection factors, and common applications.

A comparative study between air cooling and liquid cooling

Nov 5, 2021 · Two different cooling systems for the module are then designed and investigated including a U-type parallel air cooling and a new indirect liquid cooling with a U-shape cooling

Air cooling and heat dissipation performance of single-layer battery

Due to the fact that each battery pack module is equipped with a fan, air cooling and heat dissipation performance research can be conducted on single-layer battery cabinets. 1.1

Battery Cooling Tech Explained: Liquid vs Air

May 9, 2025 · Air Cooling or Liquid Cooling, Which is Suitable? Ultimately, the choice depends on scale and requirements. Air cooling remains viable for low

A review of power battery cooling technologies

May 1, 2025 · The importance of multi-objective optimization, which aims to balance cooling performance, system weight, power consumption, environmental impact, and equipment cost,

Innovative heat dissipation solution for air-cooled battery

Apr 30, 2025 · The present study investigates a novel battery thermal management system employing air cooling with a stair-step configuration. Experimental research focused on a

Performance analysis of liquid cooling battery thermal

Nov 30, 2023 · An efficient battery thermal management system can control the temperature of the battery module to improve overall performance. In this paper, different kinds of liquid

Development and Analysis of a Modified H-Type

Apr 16, 2025 · Abstract. Thermal management of lithium-ion batteries is an important design consideration for electric vehicles (EVs) as it affects the

Study on performance effects for battery energy storage

Feb 1, 2025 · By increasing air supply volume, cooling effect of cooling system can be improved. Design A has lower temperature standard deviation than other three designs. Effect of

Frontiers | Research and design for a storage

Aug 9, 2024 · Compared with conventional air cooling, power consumption is reduced. The temperature consistency design of the energy storage battery

2025-01-8193: Research on Heat Dissipation of Cabinet of

According to the actual size of a company''s energy storage products, this paper also considered the liquid cooling cooling system, air cooling cooling system and lithium-ion battery module

6 FAQs about [Research on domestic battery cabinet air cooling]

How to improve the air cooling effect of battery cabin?

The air cooling effect of battery cabin was improved by adding guide plate. There is better consistency between the modules and the modules can operate at more appropriate environment temperature. Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence.

Does guide plate influence air cooling heat dissipation of lithium-ion batteries?

Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling.

Does air-cooled lithium-ion battery pack improve thermal performance?

Verma SP, Saraswati S. Numerical and experimental analysis of air-cooled Lithium-ion battery pack for the evaluation of the thermal performance enhancement. J Energy Storage 2023; 73: 108983. 9. Zhang SB, He X, Long NC, et al. Improving the air-cooling performance for lithium-ion battery packs by changing the air flow pattern.

Does guide plate influence air cooling heat dissipation?

Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling. Firstly, a simulation model is established according to the actual battery cabin, which divided into two types: with and without guide plate.

How to simulate a battery cabin?

Firstly, a simulation model is established according to the actual battery cabin, which divided into two types: with and without guide plate. Then, at the environment temperature of 25°C, the simulation air cooling experiment of the battery cabin was carried out. The working condition of module was 1C, and the air speed was set to 4m/s.

Why is thermal management of battery energy storage important?

Dongwang Zhang and Xin Zhao contributed equally to this work. Battery energy storage system occupies most of the energy storage market due to its superior overall performance and engineering maturity, but its stability and efficiency are easily affected by heat generation problems, so it is important to design a suitable thermal management system.

Industry Information

- Amman Uninterruptible Power Supply Model

- Outdoor power station factory in Durban

- N Djamena Photovoltaic Panel Accessories Manufacturer

- Battery 12 volt inverter

- Which energy storage method has the lowest cost

- Serbia communication base station inverter distribution

- Suriname Energy Storage Solar Power Generation Project

- Bangkok grid-side energy storage project

- Three-phase inverter average value control

- Is it safe to use outdoor power supply at night

- Best solar power storage in China Seller

- ASEAN energy storage power station opens

- Main circuit breaker factory in Turkmenistan

- Bess battery storage for sale in Botswana

- China usb c power station for sale company

- Base station integrated energy cabinet bidding

- Swedish electrochemical energy storage power station

- Energy storage pumped photovoltaic power station

- What is the electricity cost of 5G base stations in Algeria

- Costa Rica Energy Storage Solution

- The design of energy storage container is very simple

- Inverter for home and outdoor use

- Outdoor power supply replacement

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

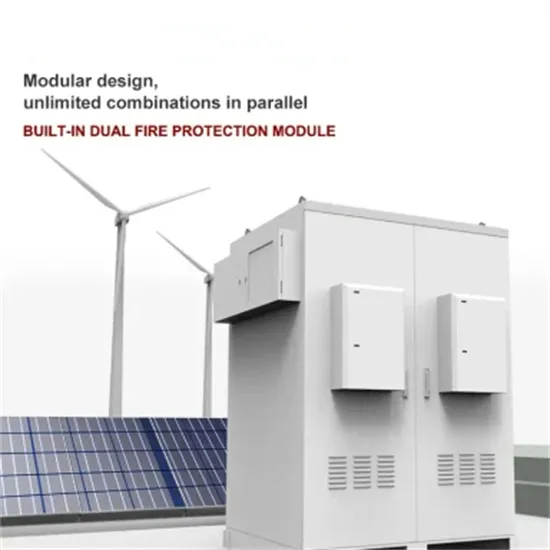

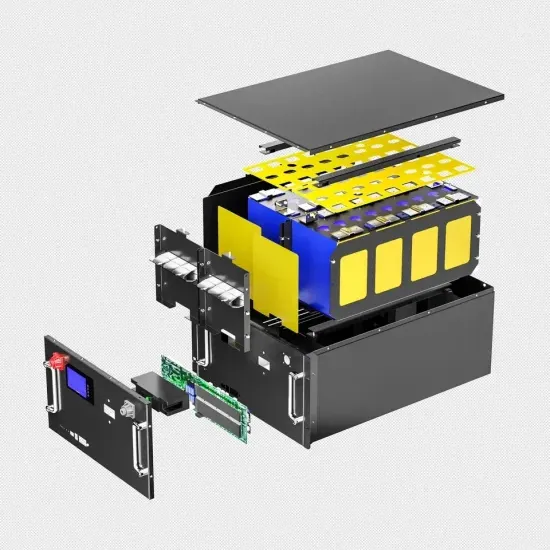

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.