How to Better Analyze Battery Data Using AI

Jun 23, 2025 · This webinar elaborates how to better analyze data using AI in the context of battery testing. The webinar discusses the rationale behind the need for better data analysis,

How to Extract and Process Data from a Smart Battery

Jul 28, 2025 · Track key battery data like voltage, current, temperature, and state-of-charge to monitor performance and predict battery health. Use the right hardware and communication

How to Analyze Battery Performance Using EIS

Jun 20, 2025 · The performance and longevity of batteries are critical in various applications, from consumer electronics to electric vehicles. EIS allows researchers and engineers to delve into

How to Better Analyze Battery Data Using AI

Jun 7, 2025 · This webinar elaborates how to better analyze data using AI in the context of battery testing. The webinar discusses the rationale behind the need for better data analysis, including

How to Better Analyze Battery Data Using AI

Jul 17, 2025 · This webinar elaborates how to better analyze data using AI in the context of battery testing. The webinar discusses the rationale behind the need for better data analysis,

Role of Battery Data Analysis in Accelerating Battery R&D

Mar 5, 2024 · Battery data analysis is a powerful tool accelerating battery R&D. It streamlines data management, enabling faster innovation across materials, performance, and lifespan

How to Analyze Battery Test Results: A Guide for Engineers

Dec 27, 2023 · Learn how to interpret battery test data and evaluate your battery''s performance, reliability, and safety with these steps and tips for electrical engineers.

How to Better Analyze Battery Data Using AI | AVL

Mar 13, 2025 · This webinar elaborates how to better analyze data using AI in the context of battery testing. The webinar discusses the rationale behind the need for better data analysis,

Data Analysis and Feature Extraction for Battery

This example shows the workflow of organizing and analyzing raw data from battery test cyclers. The example, using batteryTestDataParser and

How To Get High Precision Battery State Data in

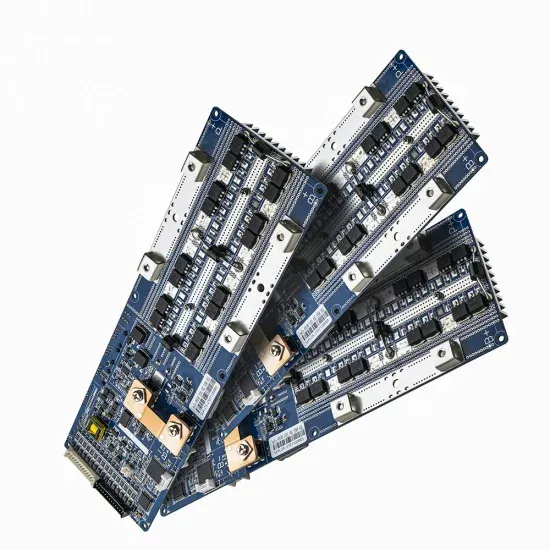

Sep 27, 2024 · Battery Management System is integral to any battery-powered technology, especially in electric vehicles and energy storage systems. The

Role of Battery Data Analysis in Accelerating Battery R&D

Mar 5, 2024 · Unlock faster battery innovation! Discover how battery data analysis is improving battery R&D, from optimizing materials to predicting predicting lifespan.

How to Extract and Process Data from a Smart Battery

Jul 28, 2025 · How to process data from a smart battery: extract key metrics, clean data, and analyze battery health for accurate forecasting and optimized performance.

Unlocking the Power of Data: A Guide to Effective Battery

Data analysis is the cornerstone of effective battery testing. By focusing on key features such as data collection, visualization, and report generation, end users can optimize their battery

Battery Archive

Dec 31, 2022 · Newsletter We publish more data to Battery Archive and make software updates to the Battery Lifecycle Framework every 2 months. By

How to Read Battery Report Windows 10: A Comprehensive

Oct 2, 2024 · Unlock your laptop''s performance insights with our guide on how to read the Battery Report in Windows 10. Learn to check battery health and usage trends easily.

BMS + Data Analytics: A tool to get the most out

Nov 15, 2022 · By establishing a "bidirectional" communication system between the battery (specifically, between the BMS and its software) and the data

How to read and interpret a battery''s datasheet

Sep 29, 2020 · If you are developing an IoT device, chances are that you''ll need a battery to power your connected object. Batteries come in all sorts of shapes and chemistries and not all

How to Generate and Analyze a Battery Report on Your

If you''re concerned about your laptop''s battery performance, generating a battery report can provide valuable insights. Here''s a step-by-step guide on how to create and analyze a battery

Utilities for reading and manipulating battery testing data

Jan 6, 2024 · Battery data plays a crucial role in understanding the behavior and performance of batteries. This data can include parameters such as voltage, temperature, Current, and state

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

How to read battery report Windows 11

Mar 10, 2025 · In this article, we will explore how to generate and read the battery report on Windows 11. We will discuss the importance of battery reports, the steps to create one, and

Battery Sizing Software | Battery Sizing Analysis

Battery Sizing module determines the number of strings, number of cells, and cell size of a battery for a designated duty cycle and compensates for real-life

How to Better Analyze Battery Data Using AI | AVL

Jan 29, 2025 · This webinar elaborates how to better analyze data using AI in the context of battery testing. The webinar discusses the rationale behind the need for better data analysis,

Battery Data Acquisition and Analysis Using MATLAB

Feb 13, 2014 · MathWorks engineers will demonstrate how to acquire and analyze battery discharge data using MATLAB. They will show techniques for aligning data traces with

How to Better Analyze Battery Data Using AI | AVL

Jul 5, 2025 · This webinar elaborates how to better analyze data using AI in the context of battery testing. The webinar discusses the rationale behind the need for better data analysis, including

New energy battery cabinet detection line failure

Accurate detection and diagnosis battery faults are increasingly important to guarantee safety and reliability of battery systems. How to analyze battery potential failure data? Based on the

Bamomas

Keep batteries in good shape with remote battery monitoring and analytics Gain visibility into battery health and performance, maximise battery lifetime, plan

How to read and interpret a battery''s datasheet

Sep 29, 2020 · This article intends to explain and clarify in plain English the most relevant specifications that you may find in a primary battery datasheet, how to analyze the battery''s

How to Better Analyze Battery Data Using AI | AVL

Apr 27, 2025 · This webinar elaborates how to better analyze data using AI in the context of battery testing. The webinar discusses the rationale behind the need for better data analysis,

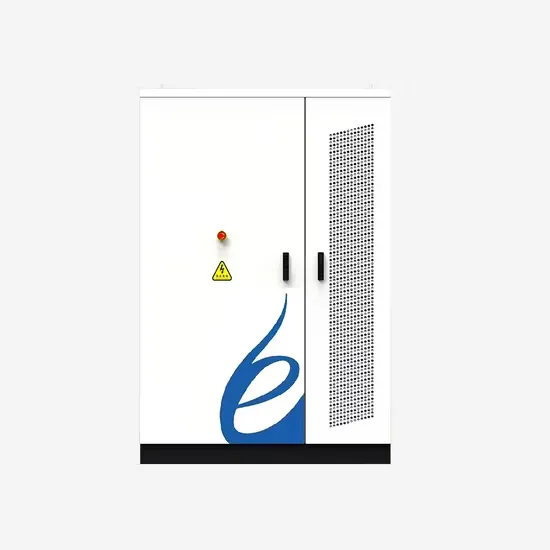

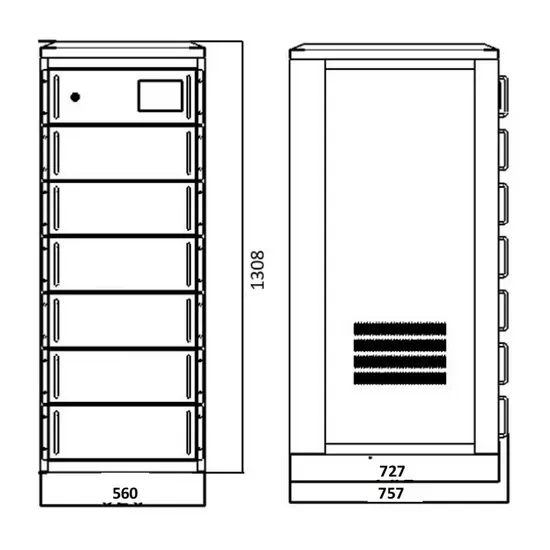

How to design an energy storage cabinet: integration and

Jan 3, 2025 · Data collection and analysis: Collect the working data of energy storage cabinets (such as battery voltage, current, temperature, etc.) in real time, and optimize the energy

How to Better Analyze Battery Data Using AI | AVL

Jun 10, 2025 · This webinar elaborates how to better analyze data using AI in the context of battery testing. The webinar discusses the rationale behind the need for better data analysis,

Smart Battery Dashboards and Pools Overview

Mar 19, 2025 · The Smart Battery dashboard enables you view and analyze your battery data, regardless of device type. You can decide which batteries are performing well and which need

Understanding Windows 10 laptop battery

May 1, 2021 · A: Battery life continues to be one of the most common complaints for all of our electronic devices, but understanding some basics can help

6 FAQs about [How to analyze battery cabinet data]

How can one analyze a Lithium Ion Battery?

One can analyze a Lithium Ion Battery through two main methods: ex situ Battery disassembly to analyze Individual Components Upon change/failure, and in situ Analysis under load, in a working environment to observe real-time cell activity. During in situ analysis, you can view the battery during operation/charge cycles and put it into a ‘real’ situation. Additionally, assemble a battery for Proactive Analysis.

Can you model every temperature on a battery graph?

But be warned, one can’t model every temperature on this graph so if your operating temperatures are outside of the given range, you’ll need to double check the information with the battery manufacturer. How to read the graph?

How much current does a SAFT battery use?

Now let’s compare the performances of this battery to another one featuring the same specs. At 20°C and with a peak current consumption of 50 mA, there isn’t any data. Moreover, for a lower level of current i.e. 2 mA, the level of voltage differs (3.6 V for Saft, 3.4 V for the competitor).

How do I know if my battery is bad?

Check your cut-off voltage on the Y axis. If the coordinates of the point formed by the temperature and the discharge current go below your cut-off voltage, the battery won’t be able to power your device correctly. E.g.: Your application will be deployed inside a house and will therefore be exposed to temperatures averaging 20°C (orange line).

How does Battery behavior change over a lifetime?

Its behavior evolves over the battery’s lifetime depending on various parameters such as the temperature in the field, or the current drain. This is why you’ll find in the datasheet several graphs that model the battery’s behavior over different temperatures and according to various current drains (on page 2 in the example below).

How does temperature affect battery performance?

Conversely, lower temperatures tend to reduce the rate of self-discharge and preserve the initial energy stored in the battery but the inner active materials are less reactive at cold temperature so that the battery system, becomes less powerful at cold temperature (lower voltage and power).

Industry Information

- Iraq Photovoltaic Grid-connected Inverter

- Manufacturer direct sales of 8KW home solar photovoltaic panels

- Air-cooled and water-cooled energy storage system

- Forklift lithium battery pack land transportation requirements

- Dominica promotes energy storage system

- Explosion-proof pressure relief energy storage cabinet

- Energy storage system integration performance

- Wholesale 12v circuit breaker in Nigeria

- Flywheel Energy Storage Mechanical Battery

- DElectrochemical energy storage

- Bamako Solar Soft Photovoltaic Panel

- Tiraspol Liquid Cooling Energy Storage System Manufacturer

- Inverter belongs to the photovoltaic industry

- Japanese solar photovoltaic modules

- Manama UPS Uninterruptible Power Supply Wholesale Agent

- Laayoune energy storage lithium battery manufacturer

- Which is the best emergency energy storage power supply in Freetown

- European Solar Water Pumps

- Manufacture of large outdoor power supplies

- Tender for maintenance of wind power and photovoltaic power generation in Vilnius communication base station

- Spain low power inverter price

- What are flexible photovoltaic panels

- Gambia Solar Street Light Power System

Commercial & Industrial Solar Storage Market Growth

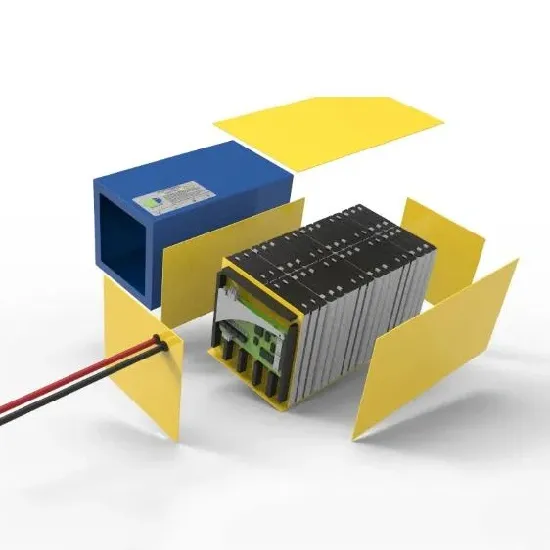

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

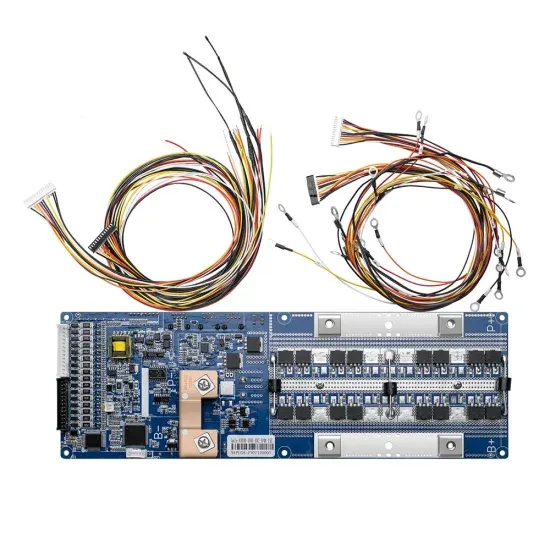

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.