Carbon emission assessment of lithium iron phosphate batteries

The cascaded utilization of lithium iron phosphate (LFP) batteries in communication base stations can help avoid the severe safety and environmental risks associated with battery retirement.

Optimization of Communication Base Station

Dec 7, 2023 · In the communication power supply field, base station interruptions may occur due to sudden natural disasters or unstable power supplies. This

Lithium-ion battery safety | Energy Safe Victoria

About lithium-ion batteries Lithium-ion batteries are a type of rechargeable battery that power almost all: laptops mobile phones e-bikes e-scooters power banks

Evaluated minimum safe distances for mobile

Aug 5, 2024 · In Table 1 are presented the minimum safe distances for GSM 900, GSM 1800 and 3G base stations, in terms of public and occupational

Environmental feasibility of secondary use of electric vehicle lithium

May 1, 2020 · The choice of allocation methods has significant influence on the results. Repurposing spent batteries in communication base stations (CBSs) is a promising option to

Lithium-Ion Batteries Hazards

Jan 17, 2024 · Hazards Lithium-ion batteries are used in e-mobility devices, consumer electronics, power tools, electric vehicles, and energy storage systems (ESS). They have a higher energy

Lithium-ion Battery Safety

Jan 13, 2025 · The hazards and controls described below are important in facilities that manufacture lithium-ion batteries, items that include installation of lithium-ion batteries, energy

【MANLY Battery】Lithium batteries for communication base stations

Mar 6, 2021 · In the future, especially after the 5G upgrade, lithium battery companies will no longer simply focus on communication base stations, but on how the communication network

Design of Lithium Battery Monitoring System Based on

Abstract. The lithium battery in the new energy system works in the wilderness environment, and its data remote monitoring is often realized based on wireless communication, and this

China''s first communication lithium battery

Jul 9, 2022 · Recently, the China Association of Communications Enterprises (CAICI) issued the "Safety Technical Requirements for Lithium Iron Phosphate

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · Recent code and standard updates have focused on fire hazards of lithium-ion batteries for ESS Important not to hinder the traditional safer chemistries and applications

Lithium-ion Safety Concerns

Feb 9, 2022 · Lithium-ion batteries are nearing their theoretical energy density limit and battery manufacturers are beginning to focus on improving

Environmental feasibility of secondary use of electric vehicle lithium

May 1, 2020 · Abstract Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles

White Paper on Lithium Batteries for Telecom Sites

Mar 3, 2025 · Focused on the theme of "building a high-quality and reliable battery infrastructure for telecom networks", this white paper discusses the safety of lithium batteries in telecom

Jiangsu issues safety standards for user-side energy storage

Jun 19, 2025 · Jiangsu issues safety standards for user-side energy storage: clarifying the minimum safe distance for energy storage power stations!-Shenzhen ZH Energy Storage -

Lithium-ion batteries: a growing fire risk

Jun 28, 2024 · Lithium-ion batteries used to power equipment such as e-bikes and electric vehicles are increasingly linked to serious fires in workplaces and

Lithium-Ion Battery Storage & Handling

Feb 25, 2025 · Establish minimum distances between battery charging stations and any combustible materials: While generally safe, the process of charging lithium-ion batteries can

Environmental feasibility of secondary use of electric vehicle lithium

Jan 22, 2020 · Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles (EVs), yet

What Are Telecom Lithium Batteries and Their

Mar 16, 2024 · Telecom lithium batteries are advanced energy storage devices that utilize lithium-ion or lithium iron phosphate (LiFePO4) technologies. They

Lithium-Ion Batteries

Jul 29, 2025 · Resources to assist fire departments with risks, response and community outreach materials related to lithium-ion battery incidents.

Lithium-ion batteries: Safe handling and storage

May 5, 2023 · Lithium batteries power many parts of everyday life. They''re increasingly used in everything from smartphones and scooters to power tools and machinery. On a larger scale,

Lithium Iron Batteries for Telecommunications Base Stations

REVOV''s lithium iron phosphate (LiFePO4) batteries are ideal telecom base station batteries. These batteries offer reliable, cost-effective backup power for communication networks. They

通信基站用耐低温钠离子电池研究与应用

MORE Sodium ion battery is a new type of secondary battery that operates by the movement of sodium ions between the positive and negative electrodes.Due to its excellent low-temperature

Carbon emission assessment of lithium iron phosphate batteries

The demand for lithium-ion batteries has been rapidly increasing with the development of new energy vehicles. The cascaded utilization of lithium iron phosphate (LFP) batteries in

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · Large telecom offices and cell sites with dedicated generators have 3 to 4 hours of battery reserve time A large telecom office may have over 400 cells and 8000 gallons of

Battery Room Ventilation and Safety

Mar 15, 2023 · This course describes the hazards associated with batteries and highlights those safety features that must be taken into consideration when designing, constructing and fitting

Lithium Batteries: Safety, Handling, and Storage

Nov 14, 2022 · Primary or Non-Rechargeable Lithium Cells Primary lithium batteries feature very high energy density, a long shelf life, high cost, and are non-rechargeable. They are generally

Safety of Lithium-Ion Batteries

Jan 1, 2014 · Lithium-ion (Li-ion) batteries have been commercially available for over two decades and currently represents state-of-the-art power source for all modern consumer electronic

Lithium Battery for Communication Base Stations Market

The global Lithium Battery for Communication Base Stations market is poised to experience significant growth, with the market size expected to expand from USD 3.5 billion in 2023 to an

Carbon emission assessment of lithium iron phosphate

Jul 29, 2024 · The demand for lithium-ion batteries has been rapidly increasing with the development of new energy vehicles. The cascaded utilization of lithium iron phosphate (LFP)

6 FAQs about [Safe distance of lithium-ion batteries for small communication base stations]

What is a lithium ion battery?

A lithium-ion battery contains one or more lithium cells that are electrically connected. Like all batteries, lithium battery cells contain a positive electrode, a negative electrode, a separator, and an electrolyte solution.

What are the OSHA standards for lithium-ion batteries?

While there is not a specific OSHA standard for lithium-ion batteries, many of the OSHA general industry standards may apply, as well as the General Duty Clause (Section 5(a)(1) of the Occupational Safety and Health Act of 1970). These include, but are not limited to the following standards:

Are lithium ion batteries flammable?

Some of these electrolytes are flammable liquids and requirements within OSHA’s Process Safety Management standard may apply to quantities exceeding 10,000 lb. Many of the chemicals used in lithium-ion battery manufacturing have been introduced relatively recently.

Can repurposed EV batteries be used in communication base stations?

Among the potential applications of repurposed EV LIBs, the use of these batteries in communication base stations (CBSs) isone of the most promising candidates owing to the large-scale onsite energy storage demand ( Heymans et al., 2014; Sathre et al., 2015 ).

What are lithium ion batteries used for?

They power devices such as mobile telephones, laptop computers, tablets, cameras, power tools, electric vehicles, and machinery, and are also used in large Energy Storage Systems (ESS). Lithium-ion batteries may present several health and safety hazards during manufacturing, use, emergency response, disposal, and recycling.

What is the recycling stage of a lithium ion battery?

In the recycling stage, the collectedLIB packs are dismantled to obtain the main components, such as battery cells, BMSs, and packaging, and various material fractions are recovered from these components separately (Table A1 in the supplementary materials).

Industry Information

- Battery price for Havana communication base station

- Hsx energy storage power supply

- Swaziland Communications 5G Indoor Base Station

- How much loss does the photovoltaic panel have through the glass

- Lithium battery storage voltage

- Manama smart energy storage battery custom manufacturer

- Containerized generators at favorable prices

- Yamoussoukro flashlight lithium battery pack

- 48 to 220 inverter

- Solar photovoltaic panels can insulate

- What to do if the communication base station loses power

- The relationship between RV and portable power supply

- 3 6 kw solar inverter factory in Nepal

- Mexican grid-connected photovoltaic solar panels

- Where can I buy assembled battery cabinets in Brunei

- 7v solar panel 20 watts

- 12v100v inverter

- Battery energy storage prices in Ho Chi Minh City Vietnam

- Roman Lithium Energy Storage Power Supply Specifications

- High quality hybrid inverters in Tunisia

- The Vatican recommends using batteries for energy storage

- Fire protection usp host and battery cabinet

- Inverter prices in Canada

Commercial & Industrial Solar Storage Market Growth

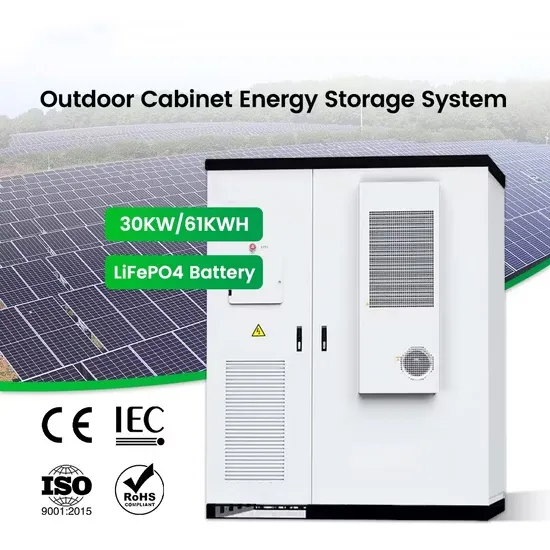

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.