Solution-Processed Thin Film Transparent Photovoltaics:

Oct 23, 2024 · Recent advancement in solution-processed thin film transparent photovoltaics (TPVs) is summarized, including perovskites, organics, and colloidal quantum dots. Pros and

Influence of the temperature on the intrinsic parameters

Jan 3, 2025 · Most of the modules present a positive value for the current thermal coefficient ( ), but the voltage and power temperature coefficients ( and ) are negative in all the cases. With

New model to study the outdoor degradation of thin–film photovoltaic

Jun 1, 2022 · The performance of four thin-film photovoltaic modules is analyzed after an initial stabilization period and a subsequent outdoor exposition. The seasonal variations and the

Temperature dependence on the photovoltaic properties

Sep 10, 2022 · Temperature dependence on the photovoltaic properties of selected thin-film modules V. Perraki, G. Tsolkas Department of Electrical and Computer Engineering,

Metastable Changes to the Temperature Coefficients of

Jul 30, 2014 · Abstract—Transient changes in the performance of thin-film modules with light exposure are a well-known and widely reported phenomenon. These changes are often the

Overview of Temperature Coefficients of

Jan 1, 2010 · With the exception of the thin film Si device (rel = -0.48 %/°C), all thin film technologies have lower values for the rel temperature coefficient for

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Experimental comparison between Monocrystalline,

May 11, 2022 · Experimental comparison between Monocrystalline, Polycrystalline, and Thin-film solar systems under sunny climatic conditions

Temperature Dependence on the Photovoltaic Properties of Selected Thin

Jul 10, 2013 · In this paper the influence of temperature on the photovoltaic parameters of amorphous silicon (a-Si) and copper indium diselenide (CIS) thin film modules has been

Influence of the temperature on the intrinsic parameters

4 days ago · The main novelty of this article is the use of a consolidated model as the SDM to perform an in-depth study of the evolution with respect increasing temperatures of six different

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · The main difference between thin-film solar panels and other types, such as monocrystalline and polycrystalline, lies in their material composition

Temperature dependence on the photovoltaic properties

Sep 10, 2022 · In this paper the influ-ence of temperature on the photovoltaic parameters of amorphous silicon (a-Si) and copper indium diselenide (CIS) thin film modules has been

Temperature-Dependent Light-Stabilized States in Thin

Sep 17, 2015 · For example, the existing qualification standard for thin-film PV modules, IEC 61646, specifies a module temperature range of 40–60 Cduring light exposure. In addition, a

Frontiers | Analysis of various degradations of

Jun 22, 2023 · This study evaluates the degradation of mono, poly, and thin-film silicon solar photovoltaic (PV) modules through visual and electrical

Effects of partial shading and temperature-dependent

Jan 1, 2025 · The partial shading of photovoltaic (PV) modules by fixed obstacles can reverse the bias of the cells in the module, resulting in extreme localised heating known as hotspots [4].

Thin Film Photovoltaics

Oct 7, 2013 · If a PV module converts about 10% of incident sunlight into electricity, it will produce about 100 W/m2. (Actually, to produce that much electricity under operating conditions, with all

Metastable changes to the temperature coefficients of thin-film

Jun 13, 2014 · Transient changes in the performance of thin-film modules with light exposure are a well-known and widely reported phenomenon. These changes are often the resul

Characterization of Performance of Thin-film PV

Apr 15, 2020 · Step 1: merge to normalised performance ratio norm PR(Pmax) and Step 2: plot in dependence of daily irradiation (bottom/left) and of average daylight module temperature.

Outdoor Degradation of Thin-Film Photovoltaic

Apr 8, 2025 · Outdoor degradation of thin-film photovoltaic modules - Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Physical Properties of EVA and PVB Encapsulant

Sep 1, 2008 · Physical Properties of EV A and PVB Encapsulant Materials for Thin Film Photovoltaic Module Applications Lee-May Huang, Hsien-Y i Hsu,

10.11648.j.ijrse.20130204.12

Sep 6, 2023 · Temperature dependence on the photovoltaic properties of selected thin-film modules V. Perraki, G. Tsolkas Department of Electrical and Computer Engineering,

Exergy analysis of thin-film solar PV module in ground

Oct 1, 2020 · The photovoltaic (PV) installations are gaining more popularity in recent years. At the same time, they experience a few challenges related to performance and land occupancy

What Are CIGS Thin-Film Solar Panels? When to

Mar 6, 2022 · Thin-film solar panels are among the most advanced and efficient power generation technologies created for the solar industry. These

Influence of the temperature on the intrinsic parameters

4 days ago · Most of the modules present a positive value for the current thermal coefficient ( ), but the voltage and power temperature coefficients ( and ) are negative in all the cases. With

Technology and Climate Trends in PV Module Degradation

Oct 3, 2013 · An understanding of the degradation mechanisms for the thin-film modules is complicated by the diversity of thin-film technology. The general observation that the fill factor

Thin-Film Transistor-Based Sensor Interface Circuits Enabling

Jun 12, 2023 · Accurate efficiency prediction, improved reliability, and extended lifetime of solar modules are the key driving factors for investment and research in photovoltaic (PV) systems.

Characterization Thin Film Modules

The report then covers the issues surrounding the measurement and analysis of outdoor performance of thin-film PV modules. The widely varying spectral responses, temperature

Degradation analysis of thin film photovoltaic modules

Dec 1, 2016 · The present study analyses the degradation of thin film photovoltaic modules corresponding to four technologies: a-Si:H, a-Si:H/μc-Si:H, CIS and CdTe, under 5 years of

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · Virtuani A, Pavanello D, Friesen G. Overview of temperature coefficients of different thin film photovoltaic technologies : Proceedings of the 25th European photovoltaic solar

Overview of Temperature Coefficients of Different Thin Film

Figure 1:. The thermostatic chamber used to realize temperature coefficient (TCO) measurements of the thin film devices. Figure 2:. Modules'' maximum power P,,, as a function of the

Thin-Film Photovoltaic Modules Characterisation Based on I-V

The characterisation of photovoltaic modules requires a specialised laboratory that guarantees precise control of irradiance and its spectrum and control of the module temperature during

Thin-film CdTe photovoltaics – The technology for utility

Oct 1, 2018 · Photovoltaics is an important energy technology for large scale energy generation. In the past few years cost of photovoltaic module manufacturing and

3 FAQs about [Thin-film photovoltaic module temperature]

What is a thin-film photovoltaic panel?

Instead of using silicon in crystalline form, they use a thin layer of photovoltaic material deposited on a substrate such as glass, plastic or metal. There are different types of thin-film panels depending on the material used, such as cadmium telluride (CdTe), amorphous silicon (a-Si) or copper indium gallium diselenide (CIGS).

What temperature should a PV module be rated at?

PV modules are in fact usually rated at Standard Test Conditions (STC = 1000 W/m2, AM1.5, 25°C), but their operating temperatures are usually significantly higher.

Which technologies are used to predict the energy output of a PV device?

Among them several thin film (TF) technologies. technologies and less for others. junctions, CdTe, CIS, thin-film silicon). to predict the energy output of a PV device. The present models. available on the European market.

Industry Information

- Liquid-cooled energy storage communication high-voltage battery cabinet price

- Lusaka Hybrid Energy s first 5G base station 2MWH

- Factory price safety breaker in Melbourne

- Clear uninterruptible power supply

- Amsterdam Photovoltaic Glass

- What is Uruguay s outdoor energy storage pcba

- Gambia containerized energy storage company

- Is a portable outdoor power supply practical

- Uninterruptible Power Supply Price for Port Vila Hospital

- Antananarivo mobile power station generator price

- China solar power to battery in Tunisia

- Relationship between energy storage and photovoltaic power

- Communication high voltage energy storage cabinet manufacturer ranking

- Vietnam lithium battery manufacturers

- 100kwh energy storage cabinet

- Solar cycle energy storage cabinet price

- Photovoltaic curtain wall in Saint Petersburg Russia

- Clean photovoltaic energy for power plants in Finland

- Yaounde container energy storage manufacturer quotation

- Nuku alofa Energy Storage BESS Price

- China hybrid inverter on grid in Laos

- Manufacturers of Sunshine Inverters

- China samite circuit breaker in Italy

Commercial & Industrial Solar Storage Market Growth

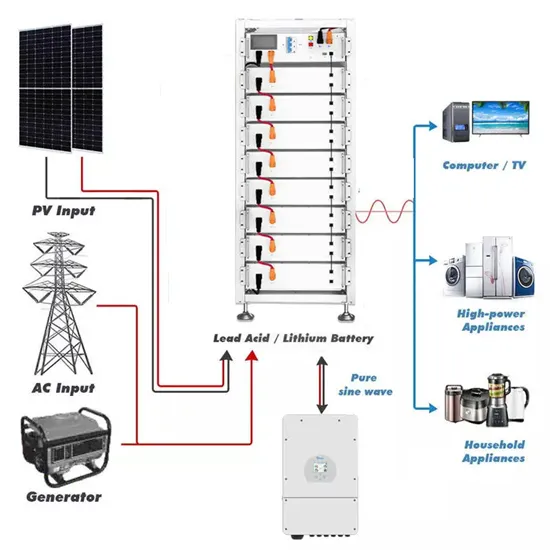

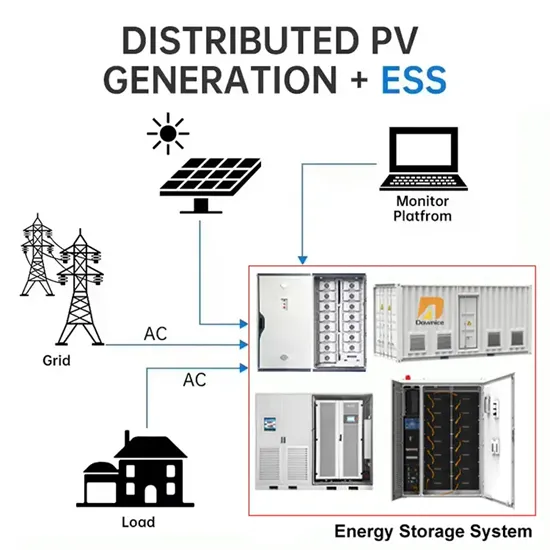

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.