Exploring LiFePO4 Battery Cell Types: Cylindrical, Prismatic,

Sep 30, 2024 · Lithium iron phosphate (LiFePO4) batteries are renowned for their exceptional safety, impressive cycle life, and superior thermal stability. They are available in three primary

CATL 3.2V 280Ah LiFePO4 Battery Cells

The CATL 3.2V 280Ah lithium iron phosphate (LiFePO4) battery is a state-of-the-art model featuring an aluminum casing, manufactured by CATL, a prominent Chinese lithium battery

LFP With NMC Range: Startup Promises

Aug 16, 2023 · Our Next Energy plan to match the range of big, pricey NMC EV batteries without the troublesome foreign raw materials and supply chain

What Are LiFePO4 Prismatic Cells? Which One Is

What Are LFP Prismatic Cells? LiFePO4 prismatic cells is a battery that encapsulates lithium iron phosphate in a Prismatic shell. The electrode tablets

Types of LiFePO4 Battery Cells: Cylindrical,

May 15, 2025 · Explore the differences between cylindrical, prismatic, and pouch LiFePO4 battery cells to choose the right type for your needs.

Prismatic vs Cylindrical LiFePO4 Cells in ESS

Feb 15, 2024 · The construction of LiFePO4 for ESS applications is a significant shift from cylindrical to prismatic cell integration. This transition is driven by the

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The ''Production Process of a Lithium-Ion Battery Cell'' guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode

EV Battery Pack Assembly

Battery is the heart of Electric Vehicles (EVs)! With technology enabling longer range batteries in a world obsessed with cutting emissions, EVs are gaining

Lithium Battery Pack Assembly: A

May 6, 2024 · Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations

Comprehensive Guide to Battery Assembly

Jun 18, 2024 · Part 2. Types of lithium batteries Lithium-ion Batteries Composition: Lithium-ion batteries (Li-ion) use lithium compounds as

Designing better batteries with LFP

Jan 15, 2025 · "The availability of lithium, iron and phosphate is a lot higher than the chemistries in many existing batteries, such as nickel, manganese and cobalt, which are rare and therefore

Cylindrical Cell Pack Assembly Line

Semi-Auto Cylindrical Battery Pack Assembly Line Machine for 18650 21700 26650 32700 Cylindrical Battery Contact Person:Louis Yang Email: Louis@chinabatterymachine

Contrasting a BYD Blade prismatic cell and Tesla 4680 cylindrical

Mar 19, 2025 · In order to provide design guidance for the development of next-generation batteries, this article presents a teardown analysis of two commercial lithium-ion batteries: the

Contrasting a BYD Blade prismatic cell and Tesla 4680 cylindrical

Mar 19, 2025 · Summary In order to provide design guidance for the development of next-generation batteries, this article presents a teardown analysis of two commercial lithium-ion

Lithium Battery Manufacturing Process Step-by

Aug 4, 2025 · Ufine Battery lithium battery manufacturing process: electrode prep, cell assembly an''d testing. Custom solutions for high-performance batteries.

Cylindrical Battery Assembly: A Simple Guide (2024 Update)

Simply put, cylindrical battery assembly involves connecting multiple individual cylindrical cells (like common AA or AAA batteries) to create a larger battery pack. This pack can provide

Safety Analysis of Lithium-Ion Cylindrical

Jan 17, 2024 · Cylindrical lithium-ion batteries are widely used in consumer electronics, electric vehicles, and energy storage applications. However,

Schematic of a conventional cylindrical 18650 Li

In contrast, the authentic lithium-ion cells performed as expected. Recommendations are provided to identify and avoid counterfeit and low

LFP Cylindrical cell

Jul 15, 2025 · Cylindrical lithium iron phosphate batteries can effectively reduce the assembly cost of batteries. The battery adopts the process of welding all tabs on the end face, which has the

LFP Battery Manufacturing Process: Components

May 16, 2024 · Overview of LFP Battery Components and Materials Lithium iron phosphate (LFP) batteries, a kind of lithium-ion battery, have obtained

ETN News | Energy Storage News | Renewable

3 days ago · ETN news is the leading magazine which covers latest energy storage news, renewable energy news, latest hydrogen news and much more.

LFP Battery Manufacturing Process: Components

May 16, 2024 · Understanding the components and materials used in LFP batteries is crucial for comprehending the intricacies of the manufacturing

LiFePO4 Cells Pack Assembly Line

Sep 13, 2024 · ALiFePO4 cells pack assembly line automates the process of assembling individual LiFePO4 cells into battery packs, ensuring consistency, precision, and efficiency.

Cylindrical Cells

Aluminium Cell Housings for Cylindrical Lithium-ion Batteries Thermal simulations reveal significant improvements in cooling performance at 3C fast-charging of

Unraveling the Mysteries of Cylindrical Cell

Jun 22, 2025 · The production of cylindrical lithium-ion cells involves several meticulously controlled steps to ensure quality and performance. The primary

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery

Round, rugged, and ready: Eve Energy sees cylindrical batteries

Apr 30, 2025 · The large cylindrical batteries accommodate multiple chemistries—including lithium iron phosphate (LFP), lithium manganese iron phosphate (LMX), and nickel cobalt manganese

The nominal voltage of custom-made lithium-ion battery packs similar to these lithium iron phosphate materials is generally called 12.8V, and some battery technicians call them 12.8V

【New message】Innovative Polymer Battery Solutions

GeB: Your dedicated cylindrical lithium battery manufacturer with 16 years of focus. We provide innovative custom solutions for your unique power requirements.

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Cylindrical 18650 Cell Lithium Lron Phosphate Battery Pack Assembly

Feb 24, 2023 · Cylindrical 18650 Cell Lithium Lron Phosphate Battery Pack Assembly Machine, Find Details and Price about 18650 Battery Production Line Power Tools Battery Pack

32140 3.2V 15Ah 48Wh LifePo4 Cylindrical

Price 32140 3.2V 15Ah 48Wh LifePo4 Cylindrical Rechargeable Lithium Battery Cells,Cylindrical cell? Lithium battery production line,battery lab pilot

6 FAQs about [Lithium phosphate battery cylindrical assembly]

What are the different types of lithium phosphate batteries?

1. Cylindrical LiFePO4 Cells Cylindrical LiFePO4 cells are the most commonly used type of lithium iron phosphate batteries. They resemble the shape of traditional AA or AAA batteries and are widely employed in applications where high power and durability are essential.

What is a lithium iron phosphate (LiFePO4) battery?

Lithium Iron Phosphate (LiFePO4) batteries have become increasingly popular for residential and commercial energy storage systems (ESS) due to their superior performance and durability. In the past, cylindrical cells were the most used battery cells, but with advancements in technology, prismatic cells are gaining popularity.

How cyclical lithium iron phosphate batteries can reduce the assembly cost?

Cylindrical lithium iron phosphate batteries can effectively reduce the assembly cost of batteries. The battery adopts the process of welding all tabs on the end face, which has the characteristics of small internal resistance, large discharge current, long cycle life, high degree of automation and so on.

What is a cylindrical lithium-ion cell?

Cylindrical lithium-ion cells are integral to powering a vast array of devices, from smartphones to electric vehicles. Understanding the assembly process of these cells not only demystifies the technology but also highlights the precision and innovation involved in their creation.

What is the production process of a lithium-ion battery cell?

The ‘Production Process of a Lithium-Ion Battery Cell’ guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode manufacturing to cell assembly and cell finishing. Furthermore, current trends and innovation of different process technologies are also explained.

What is a cylindrical battery?

Cylindrical cells, known for their high energy density and thermal management efficiency, have been the backbone of lithium battery technology, especially in consumer electronics and electric vehicles. These cells are characterized by their smaller, cylindrical shape.

Industry Information

- EK a complete manufacturer of energy storage equipment in Antwerp Belgium

- 48V communication base station wind power supply

- Power fluctuation of three-phase symmetrical inverter

- Solar cell for home use 8000 watts

- UPS battery cabinet a2 size

- Japan Osaka Energy Storage Power Supply Customized

- East African Photovoltaic Energy Storage Manufacturer

- Energy storage base station Communication base station Base station

- How long does it take for the solar panels to charge the energy storage cabinet station

- What power supply does the mobile base station use

- 12 degrees outdoor power supply

- St Georges 500 billion euro energy storage

- Kazakhstan 5g base station power consumption measurement and detection

- Harare Solar Power Supply System

- High-power lithium battery charging station cabinet

- Finland pack battery

- Blown circuit breaker factory in Suriname

- Kiribati 2025 Energy Storage Power Station

- Can wind and solar energy storage power stations make money

- 2025 Hybrid power supply for communication base stations

- Uninterruptible Power Supply Sales in Kuala Lumpur

- Pretoria Liquid Cooling Energy Storage Solution

- Cubicle switchgear manufacturer

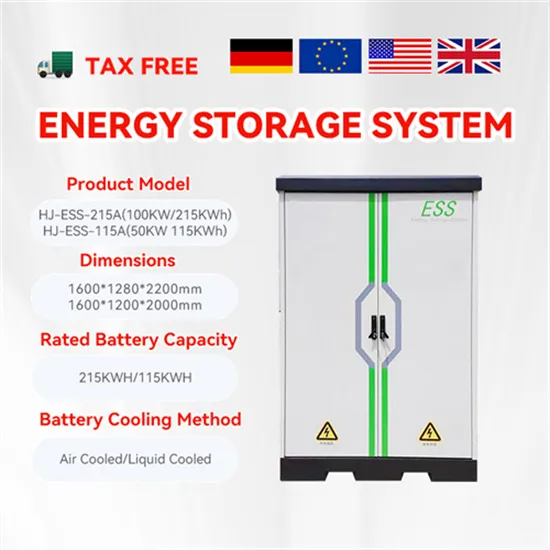

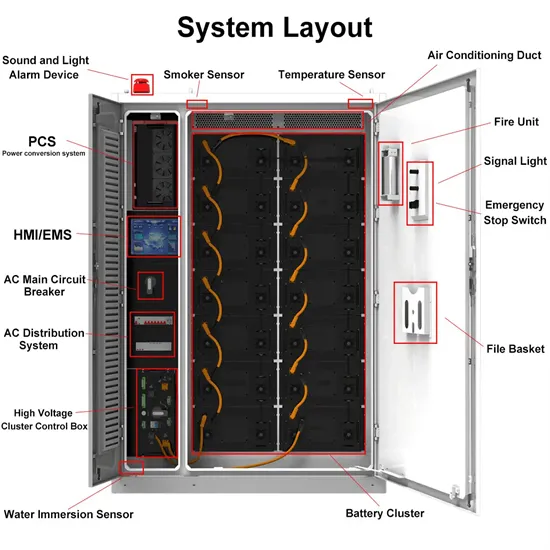

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.