How Do Laptop Inverters Work: A Comprehensive Explanation

Oct 15, 2024 · The inverter circuitry takes the low-voltage DC power from the laptop''s battery or power supply and converts it into high-voltage AC power. This AC power is then used to power

DC-DC & DC-AC Power Supply Information

Jun 5, 2017 · Voltages used in Liquid Crystal Displays besides Vdd & Vss are sometimes required in situations where a high voltage backlight, wide temperature and/or graphic LCD modules

Lcd power supply inverter

Purchase hybrid, efficient, and high-low frequency lcd power supply inverter at Alibaba for residential and commercial uses. These lcd power supply inverter have solar-driven versions too.

CCFL inverter

CCFL inverter is a circuit that is used to power the CCFL lamps (CCFL = Cold Cathode Fluorescent Lamp). These circuits usually use simple converters

LCD

NCP1351 或or NCP1219 带低待机能耗模式的反激转换控制器as Flyback with low power standby mode LX6503 Microsemi 背光控制器Microsemi Backlight controller 全桥高压逆变器,无高端驱

High Frequency Inverters | Vantom Power

Experience uninterrupted power with our high-frequency inverters. With their advanced technology and superior components, our inverters ensure a stable

High Power CCFL Backlight Inverter for Desktop LCD

Mar 19, 2018 · Normally, Q4''s collector is held near ground by the lamp-current-derived base biasing. If lamp current ceases, Q4''s collector voltage increases, overdriving the feedback

AN81

Mar 19, 2018 · The LCD utilizes a cold cathode fluorescent lamp (CCFL) as a light source to back light the display. The CCFL requires a high voltage AC supply for operation. Typically, over

LCD TV Reference Design Includes Power, Inverter Supplies

Feb 17, 2009 · The latest GreenPoint open reference design from ON Semiconductor for LCD TV power supplies combines the main system power with the backlight inverter. The 180-W High

How To Completely Test LCD Inverter Transformer

Jan 5, 2015 · The tester could read up until 2 or 3 LED lights only. However, if the LCD inverter has more than one high voltage transformer then it would be

LCD Inverter Board TPI-02-0104-K2 High Voltage Power Supply

Jan 15, 2025 · Amazon : TOSYUWIR LCD Inverter Board TPI-02-0104-K2 High Voltage Power Supply for Backlight : ElectronicsFound a lower price? Let us know. Although we can''t

power supply

Oct 13, 2020 · So I measured the power supply voltage for the tube How did you measure that, did you use a device that can accurately measure a a 40 kHz sinewave? Cold-cathode tubes

Amazon : High Voltage Inverter

5pcs High Voltage Generator DC 6-12V to 1000kV Boost Step-Up Inverter Arc Pulse Generator Power Module High Voltage Transformer 341 50+ bought in past month $1499

Understanding the Diagram of an LCD Inverter Board

It is responsible for converting the direct current (DC) power from the main power source into the high voltage alternating current (AC) power needed to power the fluorescent lamps or LED

LCD Voltage Inputs for LCD Displays Explained

This article about LCD voltage inputs was provided by: Paul Hay, Electrical Engineer. VCC, VDD, VSS, VEE, V0 Explained Monochrome character,

CCFL backlight half-bridge topology based on L6574

A 12 V or 24 V DC voltage is provided for the backlighting inverter to drive the CCFL. In order to improve the efficiency and performance of the total system both for the AC-DC power supply

LCD Inverter 125V 5kVA

Description LCD Inverter 125V 5kVA Product Description The 110V DC (125V DC) LCD Power Supply Pure Sine Wave Inverter is a new generation of intelligent MCU high frequency Power

DC Power Supply Manufacturer, DC/DC

DC AC inverter, DC voltage from 12VDC to 2000VDC, and power from 100W to 500kw. AC AC power source, single-phase or 3-phase, 10-500Hz, power

AN65

Mar 19, 2018 · The small size and battery-powered operation associated with LCD equipped apparatus mandate low component count and high efficiency for these circuits. Size

EGS002 Datasheet, Circuit Diagram Explained

Feb 21, 2025 · It has a low standby power consumption, high efficiency, and comprehensive protection features that make it suitable for small-scale

Backlight Power High Voltage LCD Inverter Board QF82V1

Backlight Power High Voltage LCD Inverter Board QF82V1 QF82V2 QF82V3 offers reliable performance and efficient power conversion. Shop now for quality and durability.| Alibaba

DC-DC & DC-AC Power Supply Information

Jun 5, 2017 · High Voltage Backlight Solutions: High voltage backlights will be typically be using DC to AC inverters, and their requirements will fall into two categories; Solutions for a high

How to Understand and Analyze an LCD TV

The backlight inverter is responsible for providing the necessary voltage to illuminate the backlight of the LCD panel. It converts the DC voltage from the

Lcd Backlight Inverter Circuit Diagram

Sep 24, 2017 · To understand exactly how a backlight inverter works, let''s take a closer look at a typical LCD backlight inverter circuit diagram. At the heart of

AN81

Mar 19, 2018 · INTRODUCTION The liquid crystal display (LCD) has become ubiquitous. It is in use everywhere, from personal computers of all sizes to point-of-sale terminals as well as

1500W Power Inverter With LCD Display

High performance at over-load capacity and impact resistance. ØIt has perfect protection functions such as input over voltage, under-voltage, overload,

LCD Inverter 125V 8kVA

Description LCD Inverter 125V 8kVA Product Description The 110V (125V) LCD Power Supply Pure Sine Wave Inverter is a new generation of intelligent MCU high frequency Power Supply

Up to 180 W High Voltage LCD TV Power and

Dec 19, 2015 · In this architecture the inverter is directly powered from a high voltage rail (HV-LIPS) to improve the system power conversion efficiency and

Lcd Inverter

Upgrade your Power Inverter with the elegant and durable Lcd Inverter.When selecting a power inverter for electronic appliances, consider factors like wattage output, wave type compatibility,

do plasma/LCD flatscreens contain high voltages?

Feb 4, 2013 · What about the backlights? LED''s are becoming more common, but cold-cathode lighting apparently requires an HV power supply. Do these typically retain high voltage after

Reference Design for an Integrated LCD TV Power and Inverter Supply

Feb 17, 2009 · This 180W High Voltage LCD Integrated Power Supply (HV-LIPS) combines the main system power with the backlight inverter. By implementing an architecture where the

INVERTER BOARD CONTROL SMD IC HIGH VOLTAGE 6 PIN

View results and find inverter board control smd ic high voltage 6 pin datasheets and circuit and application notes in pdf format.

Contrast Voltage

Voltage Generating Circuits for LCD Contrast Control Most Liquid Crystal Display modules require a Positive or Negative voltage that is higher than the logic

24Vdc to 110/220Vac Series LCD pure sine wave

This inverter power supply adopts SPWM technology controlled by MCU micro-processing, pure sine wave output, and the waveform is indeed pure. The

Understanding the Laptop LCD Inverter Circuit

The inverter circuit acts as a power supply, converting the low voltage DC power from the laptop''s battery or adapter into high voltage AC power. This AC

What Component Is in Charge of Powering An Lcd Screen?

Feb 7, 2025 · The High-Voltage Board, also known as an inverter circuit, is responsible for generating the high-frequency, high-voltage AC required to power the backlight of the LCD

High Voltage Inverter Design

Figure 5/SCM inverter control system Epilogue By the PWM control chip and high voltage driver IR2110 SG3525A consisting frequency inverter, small size, easy

10KW Solar Inverter Hybrid High Voltage Big Lcd

10KW Solar Inverter Hybrid High Voltage Big Lcd Display Solar on OFF Grid Inverter Anti-backflow Control Smart Energy System

6 FAQs about [LCD power supply high voltage inverter]

What is LCD inverter circuit?

Firstly, let’s understand the purpose of the LCD inverter circuit. The backlight in a laptop LCD screen requires a high voltage to function properly. The inverter circuit acts as a power supply, converting the low voltage DC power from the laptop’s battery or adapter into high voltage AC power.

How does a laptop LCD inverter work?

The inverter circuit acts as a power supply, converting the low voltage DC power from the laptop’s battery or adapter into high voltage AC power. This AC power is then used to power the backlight, providing the necessary illumination for the screen. Now, let’s dive into the components of the laptop LCD inverter circuit diagram.

How many LED lights can a LCD inverter read?

The tester could read up until 2 or 3 LED lights only. However, if the LCD inverter has more than one high voltage transformer then it would be easy to judge the result (comparison test). You can use the comparison method on the two transformers and locate the faulty one

What are the components of a laptop LCD inverter circuit diagram?

The key components of the laptop LCD inverter circuit diagram include the mainboard connection, inverter board, backlight connectors, and other associated connectors and cables. The mainboard connection is where the DC power is received from the laptop’s mainboard, while the inverter board converts this DC power into AC power.

Why is a laptop LCD inverter circuit diagram important?

In summary, comprehending the laptop LCD inverter circuit diagram is vital for troubleshooting and repairing LCD display issues. It allows technicians to identify components, diagnose problems, replace faulty parts, and understand the voltage and power requirements of the circuit.

What are the advantages of inverter power supply?

ØThis inverter power supply adopts SPWM technology controlled by MCU micro-processing, pure sine wave output, and the waveform is indeed pure. The unique dynamic current loop control technology ensures reliable operation of the inverter. ØLoad adaptability, including inductive load, capacitive load, resistive load, Hybrid load.

Industry Information

- High quality 1500w solar inverter in China manufacturer

- Environmentally friendly energy storage photovoltaic cells

- 12v RV outdoor power supply

- Authentic Energy Storage Products Company

- Wholesale afriipower inverter in Ireland

- Four kilowatt outdoor power supply

- Ho Chi Minh Vietnam Household Photovoltaic Inverter

- Lome Energy Storage Cabinet Lithium Battery Agent

- Madagascar new energy bms battery

- Fc2700 inverter price

- Huawei Muscat Wind Power Energy Storage Project

- Mogadishu high frequency uninterruptible power supply manufacturer

- Praia generator container

- Portugal Porto Solar Street Light Inverter

- Somalia environmentally friendly inverter custom price

- What does BMS battery management mean

- Building materials required for photovoltaic module projects

- The relationship between IGBT and photovoltaic inverter

- Photovoltaic inverter 10kw sunlight

- Tuvalu Photovoltaic Energy Storage System Project

- Large industrial battery cabinet production equipment

- Netherlands New Communication Base Station Inverter

- Avalu Energy Storage Battery Container Technology

Commercial & Industrial Solar Storage Market Growth

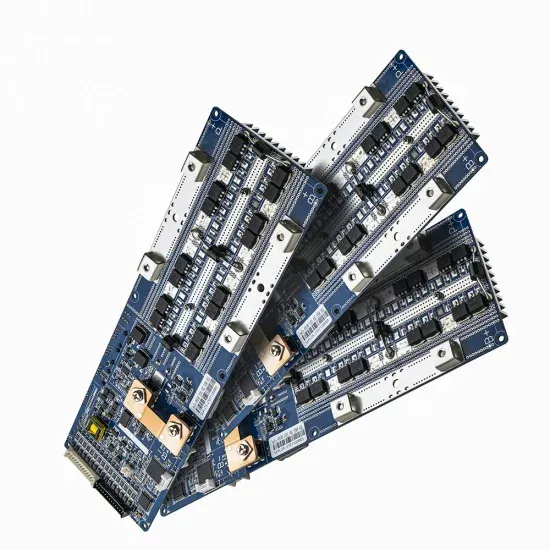

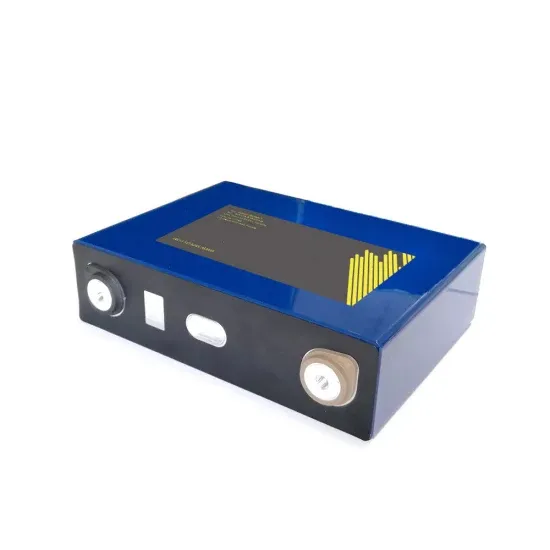

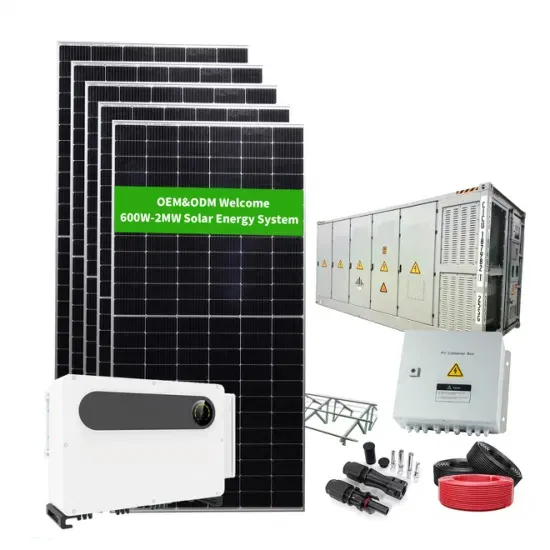

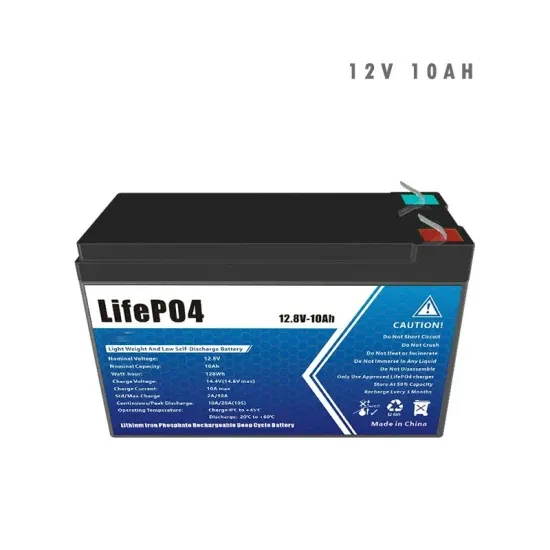

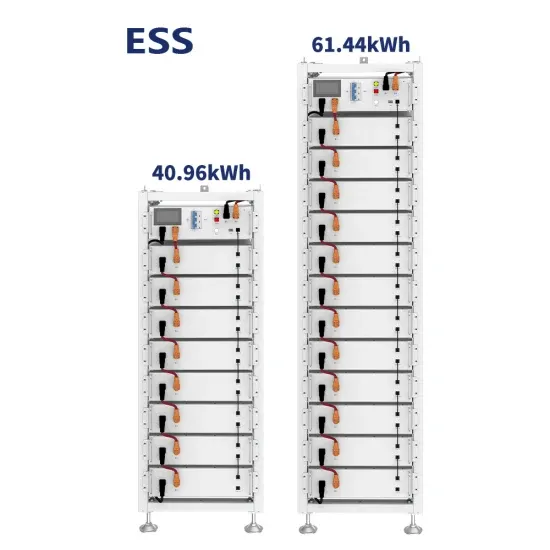

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

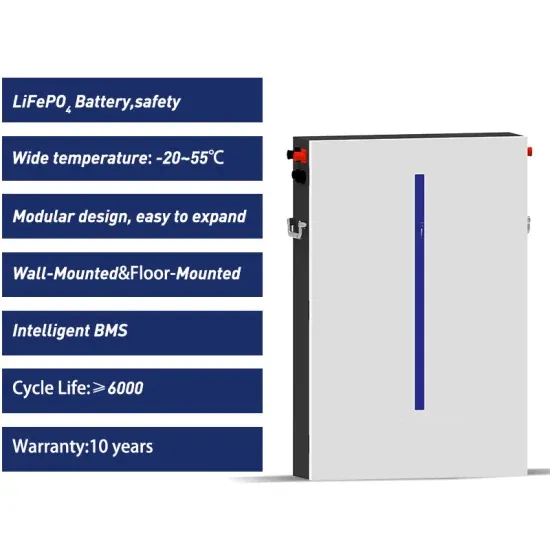

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.