Experimental data simulating lithium battery charging and

Aug 1, 2024 · This dataset provides the new energy battery field with data on the performance of the GSP655060Fe model 1600 mAh lithium-ion soft-coated battery under a variety of

In-situ temperature monitoring of a lithium-ion battery

Oct 1, 2022 · Uncertainty in the measurement of key battery internal states, such as temperature, impacts our understanding of battery performance, degradation and safety and underpins

Simulation of Dispersion and Explosion

Apr 4, 2024 · In recent years, as the installed scale of battery energy storage systems (BESS) continues to expand, energy storage system safety incidents

Battery Pressure Measurement Flexible Sensors

Flexniss provides advanced battery pressure measurement sensors designed to measure and analyze dynamic pressure forces in battery cells, modules, and

Investigation of impact pressure during thermal runaway of lithium

Jul 5, 2020 · Pressure measuring is a low-latency, low-cost, and reusable process, and a sensor can be placed at any position in a battery pack or module. As shown in Fig. 2, two waves of

NXP Tech Days 2022

Jun 7, 2022 · NBPx Battery Pressure Monitor Sensors (BPMS) integrate an 8-bit CPU and NXP-provided firmware to create the ready-to-use pressure sensors. The BPMS is capable of

Non-invasive internal pressure measurement of 18650 format lithium

Jul 1, 2022 · The dynamics of 18650 format lithium ion battery pressure build-up during thermal runaway is investigated to inform understanding of the subsequent pressure-driven venting

NXP Tech Days 2022

Jun 7, 2022 · Absolute pressure sensors for thermal runaway detection Detecting the pressure change within a sealed battery pack to provide early warning of thermal runaway.

Calorimetric method for internal pressure

Mar 14, 2019 · Dr. Carlos Ziebert, explains a calorimetric method for internal pressure measurement, which helps paving the way for safer Lithium-ion cells.

Battery Pressure Measurement | TQi | Quality Control | Tekscan

Aug 19, 2025 · Engineers understand the critical impact that changes in battery pressure can have in battery performance and safety. Tekscan''s pressure mapping technology can help you

Effects of external pressure on the performance and ageing of

May 1, 2018 · In this study, the effects of constant external pressure (0.66–1.98 MPa) on the performance and ageing of both single lithium-ion cells and coupled parallel cells that simulate

Experimental Study on Distributed Measurement

May 14, 2025 · By extracting and summing pressure data from nine measurement units of the thin-film pressure sensor during battery charge/discharge cycles, it

A Novel Method for Measuring Pressure

May 6, 2021 · Figure 2: This model demonstrates how battery designers can use pressure mapping technology to measure pressure that occurs while charging

Mechanical Measurement Approach to

Apr 22, 2024 · The propagation of thermal runaway in a battery system is safety-critical in almost every application, such as electric vehicles or home storage.

Lithium-Ion Battery Pressure Monitoring for EVs

Jul 31, 2024 · Explore advanced techniques for measuring pressure in EV batteries using pressure sensors, enhancing performance and safety.

Estimation of Explosion Pressure for Abused

Jun 14, 2010 · In this paper, we present preliminary calculations of the pressure build up within a lithium-ion cell assuming a detonation type exothermic

Impact of applied and preceding pressure on performance

Nov 15, 2024 · It was discovered that elevated preceding pressure, which might occur during battery pack production, can adversely affect the performance and reversible swelling behavior

Methods for Measuring the Mechanical Safety Vent Pressure of Lithium

Oct 24, 2006 · The Lithium ion battery is the preferred source of power for many wireless and portable consumer products. A typical battery pack with lithium ion cells features a variety of

Investigation of constant stack pressure on lithium-ion battery

Nov 25, 2023 · Two fixtures compared constant pressure and constant displacement effects on cells. The pressure fixture held pressures within −40% to +25%. Constant pressure improved

No Overheating of Lithium-Ion Batteries Thanks to Pressure Measurement

Aug 1, 2025 · Accurate pressure measurement makes an essential contribution to the safety and efficiency of lithium-ion batteries – especially during development. Sensors like the ATM.1ST

Enhancing Li-Ion Battery Safety

Feb 26, 2024 · Enhancing Li-ion battery safety: Integrating Pressure Relief and Breather Devices for Overpressure Mitigation for battery safety.

Stack Pressure Measurements to Probe the

Aug 24, 2021 · Although solid-state batteries with lithium metal could enable higher energy density and better safety characteristics than Li-ion batteries,

Battery Monitoring and Pressure Measurement

6 days ago · Here''s why integrating pressure measurement into your battery monitoring process can be a game-changer. 1. Understanding the Role of

Battery Pack Measurement Handbook:

Sep 18, 2023 · The analysis of measurement results aids in optimizing battery management systems, enhancing efficiency, safety, and overall longevity of LiB packs. This handbook

Battery Monitoring and Pressure Measurement

6 days ago · As battery technologies evolve to meet growing demands for electric vehicles, energy storage, and portable electronics, effective monitoring

How to Measure the Internal Resistance of Lithium Batteries

Aug 7, 2025 · Measure internal resistance of lithium batteries using DC, AC, EIS, or analyzers for accurate battery health, safety, and performance assessment.

Experimental Study on Distributed Measurement

May 14, 2025 · By analyzing the pressure distribution and evolution data during long-term cycling, the study reveals the dynamic patterns of internal pressure

Mapping Pouch Cell Pressure Distribution in

Jul 2, 2024 · Figure 1. Schematic experimental setup: The pouch cell (orange) and pressure mapping sensor (blue) are situated between the compression

Battery Design & Testing | Measure Battery Pressure and

Aug 18, 2025 · Measuring Battery Pressure in Real Time Pressure and Temperature Mapping in real-time. I-Scan provide a dynamic view of surface pressure across battery housings, fixtures,

A stack pressure based equivalent mechanical model of lithium

Apr 15, 2021 · By measuring the stack pressure, the battery thickness can be predicted by the proposed model, and accordingly, the battery states can be estimated. So the proposed

Battery Cell Swelling Performance Test

May 22, 2025 · Usually when testing the cell swelling behavior, it is necessary to control different boundary conditions to obtain changes in the swelling

Experimental study on the internal pressure evolution of

Nov 20, 2024 · The safety problems of lithium-ion batteries, such as fire and explosion, have become the main issues constraining the rapid development of electrochemical energy

A flexible integrated temperature-pressure sensor for

Mar 1, 2025 · Temperature and pressure variations are the key early warnings for the thermal runaway safety monitoring of lithium batteries. Although flexible temperature and pressure

A Method to Predict Swelling Force of Prismatic Cells during

Jun 20, 2025 · This paper presents a prediction method of the swelling force for lithium-ion battery during charge-discharge cycles. It integrates simulation techniques with electrode

Measurement of gas pressure inside large-format prismatic lithium

Dec 1, 2020 · We show for the first time that measuring the internal gas pressure is also possible for large-format prismatic cells and by using miniaturized pressure sensors that can be

Best practices in lithium battery cell preparation and evaluation

Sep 9, 2022 · Improved lithium batteries are in high demand for consumer electronics and electric vehicles. In order to accurately evaluate new materials and components, battery cells need to

Lab Battery Pressure Distribution Measure System For Lithium Battery

Jul 28, 2025 · the quantitative characterization of the stress distribution on the surface of LIB can provide a deeper perspective for the battery stress analysis, assist technicians to analyze the

Cell Electrode Pressure

Jan 6, 2023 · The influence of an applied mechanical pressure on the electrochemical performance and the aging of 1.4 Ah graphite/NMC622

6 FAQs about [Lithium battery pack pressure measurement]

What is a pressure mapping application for EV batteries?

Pressure mapping applications for EV Batteries. Flexible Tekscan Model 7800 matrix sensor wraps around battery components. The Model 7800 is designed specifically for battery testing. This flexible, thin sensor wraps around the cell and between layers to provide a 360◦ view of battery pressure.

What is a battery pressure sensor?

Power Battery pressure measurement sensors are critical for tracking pressure changes during the charge and discharge cycles of lithium-ion batteries. By measuring these pressure changes, you can optimize battery performance, prevent potential thermal runaway, and increase overall battery lifespan. Optimize battery performance.

How does stack pressure affect lithium-pouch cells?

Two fixtures compared constant pressure and constant displacement effects on cells. The pressure fixture held pressures within −40% to +25%. Constant pressure improved discharge power and resistance up to 4% and 2.5%. Current research involving applying stack pressure to lithium-pouch cells has shown both performance and lifetime benefits.

How does pressure mapping improve battery performance & safety?

How Pressure Mapping Insights Improve Battery Performance and Safety - Charging and discharging causes changes in temperature, electrochemistry, or volume expansion. Measuring changes in pressure can tell you how the mechanics of the internal components are affected.

How does constant pressure affect lithium-ion cells?

A constant pressure fixture was designed, built, and tested for lithium-ion cells. Two fixtures compared constant pressure and constant displacement effects on cells. The pressure fixture held pressures within −40% to +25%. Constant pressure improved discharge power and resistance up to 4% and 2.5%.

What is a flexniss battery pressure sensor?

Flexniss provides advanced battery pressure measurement sensors designed to measure and analyze dynamic pressure forces in battery cells, modules, and packs. These sensors offer real-time data that help optimize battery design and enhance performance, ensuring efficiency during critical stages of battery development.

Industry Information

- Wholesale main power breaker in Guatemala

- Moldova new energy 5g base station battery

- How much is the price of outdoor communication battery cabinet communication power supply in Peru

- Renovation of uninterruptible power supply

- Sierra Leone Mobile Telecommunications Base Station

- Factory price 1000kw inverter in Guyana

- How much is the solar photovoltaic curtain wall in Greece

- Wholesale main breaker switch in Mozambique

- 15kw hybrid inverter in China in Ghana

- Havana 30W Solar Street Light

- Uninterruptible power supply price for Congo data center

- Battery energy storage cabinet and price

- Apia Inverter 24V

- Simple energy storage system factory price

- What is the voltage of lithium battery pack

- Ukrainian uninterruptible power supply wholesale price

- Tbilisi largest capacity inverter manufacturer

- Uninterruptible power supply costs in Sao Tome

- 50MW energy storage power generation

- South Africa lithium battery cylinder price

- Russian power frequency isolation 300kw inverter

- Battery 60v plus inverter

- Ecuador lithium battery energy storage cabinet quotation

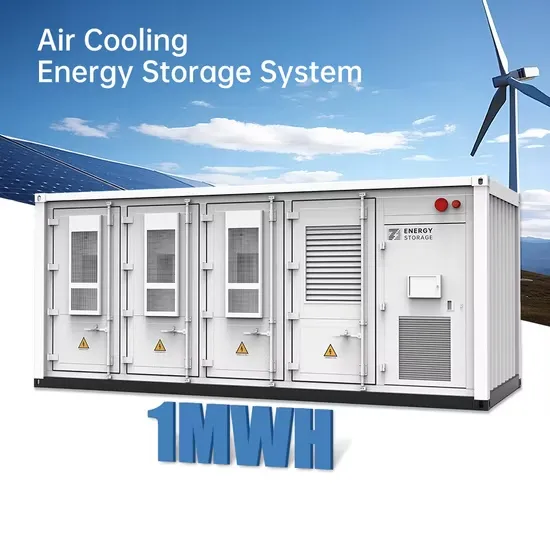

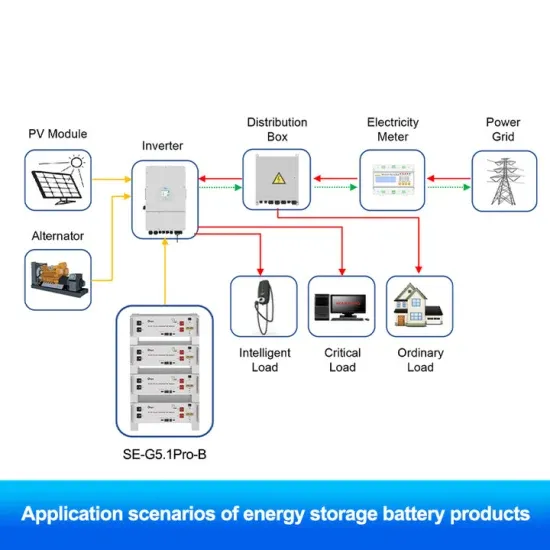

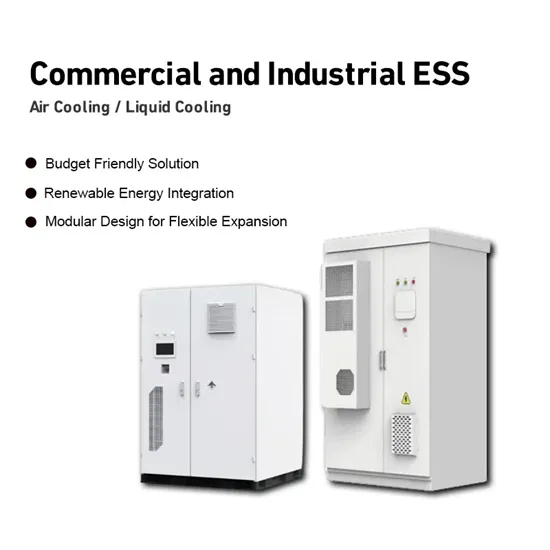

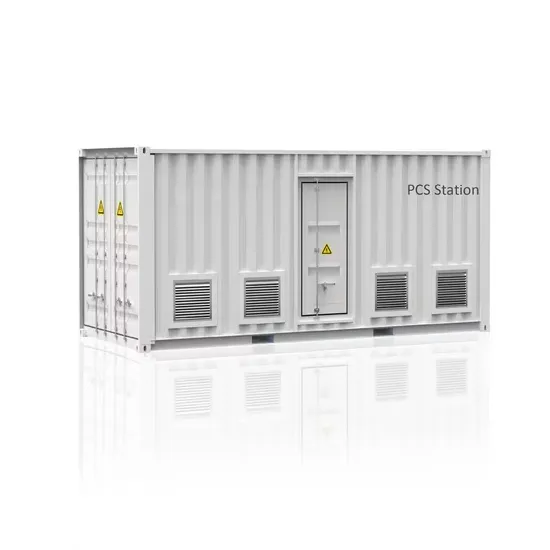

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

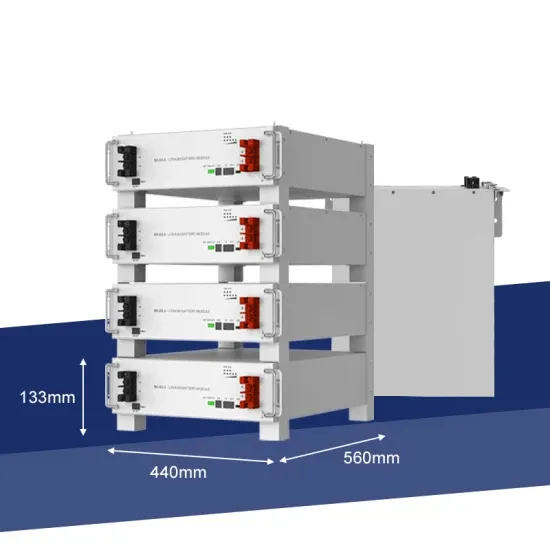

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.