Energy Storage Innovations: Inside Germany''s Cutting-Edge Factory

Mar 3, 2024 · When you think of energy storage German factory operation, what comes to mind? Precision engineering? Renewable energy leadership? Or maybe just really good beer

Tesla''s Shanghai Super Factory Launches Megapack Production for Energy

Feb 13, 2025 · Tesla builds its storage factory in Shanghai to leverage China''s large-scale manufacturing and quick response capabilities, addressing the Megapack production shortfall.

Design Engineering For Battery Energy Storage

Aug 8, 2025 · BESS Design & Operation In this technical article we take a deeper dive into the engineering of battery energy storage systems, selection of

How to Successfully Run a New Energy Storage Cabinet Factory Operation

With global demand for battery storage projected to hit $546 billion by 2035 (BloombergNEF), launching a new energy storage cabinet factory operation isn''t just smart – it''s like catching

Top 10 battery energy storage manufacturers in

3 days ago · This article will focus on top 10 battery energy storage manufacturers in China including SUNWODA, CATL, GOTION HIGH TECH, EVE, Svolt,

Tesla Shanghai Megafactory officially goes into operation

Feb 14, 2025 · The first Megapack, an ultra-large commercial electrochemical energy storage system, has already rolled off the production line, signaling a new phase for Tesla''s operations

BESS Failure Incident Database

4 days ago · About EPRI''s Battery Energy Storage System Failure Incident Database The database compiles information about stationary battery energy

The BESS System: Construction, Commissioning,

4 days ago · The Industrial and Commercial (C&I) Energy Storage: Construction, Commissioning, and O&M Guide provides a detailed overview of the

DS 5-33 Lithium-Ion Battery Energy Storage Systems

Mar 10, 2024 · Energy storage systems can be located in outside enclosures, dedicated buildings or in cutoff rooms within buildings. Energy storage systems can include some or all of the

China Economy: Tesla''s new Megafactory for energy storage

Feb 11, 2025 · The new factory will focus on producing Megapack systems, with an expected annual capacity of 10,000 units, equivalent to an energy storage capacity of nearly 40 gigawatt

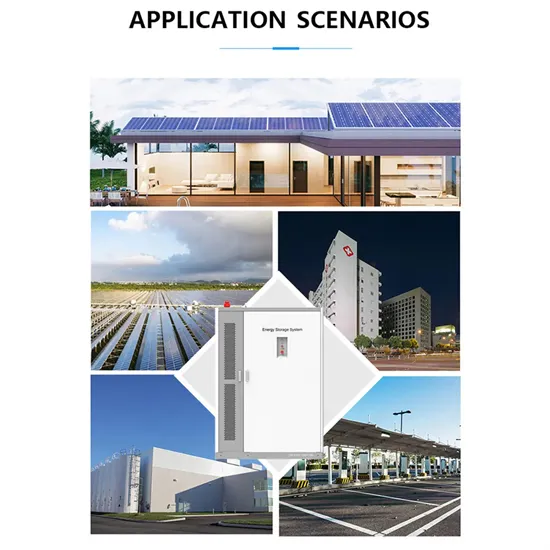

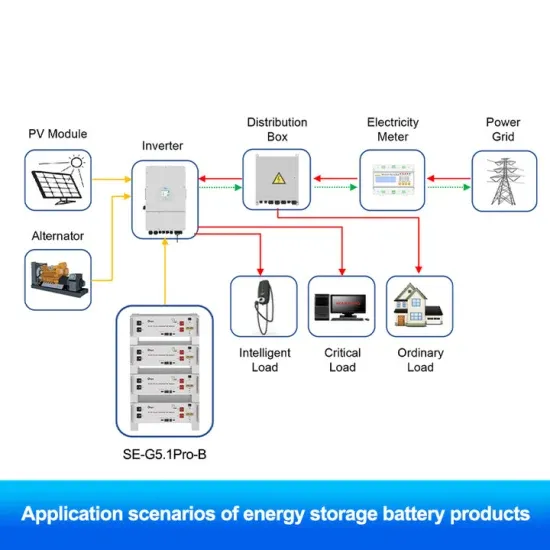

Energy Storage Container

Custom Energy Storage Solutions: We provide walk-in/non-walk-in energy storage containers, liquid cooling cabinets, marine energy storage containers

Battery Pack Assembly Process Series 7

Jun 6, 2025 · Whether it is used for new energy vehicles or energy storage scenarios, the core function of the battery pack is to store energy. "If the battery pack is compared to a soldier in

Energy storage container battery assembly drawings

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

News

Oct 19, 2022 · Pre-installed energy storage container has completed the assembly, installation and factory inspection and testing of the whole system

Battery Pack Assembly Process Series 7

Jun 6, 2025 · The manufacturing quality of energy storage containers highly relies on precise and reliable equipment support - whether it is the production consistency of battery units, the

BESS 2.5MW-5MWh Battery Energy Storage System 40ft ESS Container

The UEI-BESS-2.5MW / 5MWh is a turnkey containerized energy storage solution engineered for grid-scale and commercial energy management. Housed in a prefabricated 40ft container, the

Tesla battery Megafactory in Shanghai launches

Feb 11, 2025 · Tesla''s energy storage plant in Shanghai''s Lin-gang Special Area commenced operation on Feb 11, as the assembly line started the production

Energy storage container battery assembly solution

ABB''s containerized energy storage solution is a complete,self-contained battery solution for a large-scale marine energy storage. The batteries and all control,interface,and auxiliary

Why 20ft ISO Containers Are Widely Used in

Mar 23, 2025 · Discover the key advantages of using 20ft ISO containers for battery energy storage systems (BESS), including modularity, transportability,

Energy storage container battery assembly sequence

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

Saft opens 480MWh energy storage system

Nov 12, 2020 · The new factory will solely focus on the assembly of ESS containers, and will have the capability of producing 200 containers per year,

Energy storage containers Manufacturer

We produce containers as energy storage: modular, scalable and mobile, ensuring effective energy management and safety. Perfect for companies.

OEM |BESS Container|Billion Electric

Billion Electric Group has established its first energy storage container assembly plant in Taiwan, combining international standard container design and fully

Megapack – Utility-Scale Energy Storage | Tesla

Apr 29, 2025 · Megapack is a utility-scale battery that provides reliable energy storage, to stabilize the grid and prevents outages. Find out more about

Container shell,Energy storage container

Aug 8, 2025 · Energy storage containers, characterized by their high degree of modularization, ease of transportation, and installation, have emerged as one of the future directions for

Intensium Energy Storage Systems | Saft

6 days ago · The Intensium® ranges are standardized to deliver a consistent and holistic design that scales up to multi-megawatt systems and are ready to plug

Global Large-Scale Energy Storage 2025 | Market & Tech

Jun 13, 2025 · Explore the 2025 global large-scale BESS market: deployment data, cell breakthroughs, safety innovations, digital O&M, and long-duration trends to 2030.

HOW TO DESIGN A BESS (BATTERY ENERGY

Mar 11, 2023 · The design of a BESS (Battery Energy Storage System) container involves several steps to ensure that it meets the requirements for safety,

How Sungrow Energy Storage Container Assembly Powers

Sungrow''s Secret Sauce: Engineering Meets Wit a shipping container walks into a solar farm. The foreman asks, "Why the long face?" Turns out it''s a Sungrow storage unit packed with enough

Energy Storage System

Aug 20, 2025 · CATL''s energy storage systems provide energy storage and output management in power generation. The electrochemical technology and renewable energy power generation

2030.2.1-2019

Dec 13, 2019 · Scope: This document provides alternative approaches and practices for design, operation, maintenance, integration, and interoperability, including distributed resources

Welcome to GTI Fabrication

GTI specializes in the design, engineering, fabrication, integration and deployment of custom modular structures, ISO shipping container based

Tesla starts production at Shanghai Megapack

Jan 2, 2025 · Tesla has started trial production at its Megapack assembly plant in Shanghai, China, state-owned news reported this week (31 December).

fenrg-2022-846741 1..15

Mar 30, 2022 · The earliest application of prefabricated cabin type energy storage in power grids is originated in Europe and North America, where the energy storage container (ESC)

Iron flow battery factory under construction in

Jul 7, 2022 · Installation of a grid-scale ESS Inc Energy Warehouse flow battery energy storage container unit at a project site. Image: ESS Inc. Construction

Utility Battery Energy Storage System (BESS) Handbook

Oct 7, 2024 · Research Overview Primary Audience Utility project managers and teams developing, planning, or considering battery energy storage system (BESS) projects.

6 FAQs about [Energy storage container assembly factory operation]

How to install a containerized energy storage system?

Use an insulating heat-shrinkable tube for secure terminal fit and label wires clearly. Clean up any foreign objects in the distribution cabinet. Connect all metal shells within the energy storage box to form a grounding network using good conductors or dedicated grounding strips. 6. Containerized Energy Storage System Installation Complete

What is Tesla's Shanghai megafactory for energy storage?

The Shanghai Megafactory for energy storage is Tesla's first such facility outside the United States. Construction commenced in the Lin-gang Special Area on May 23 last year, and the factory achieved the milestone of producing its first product just nine months after acquiring the land.

How many kWh can a Tesla megafactory store?

Each unit can store more than 3,900 kWh of electricity. At the launch ceremony, Mike Snyder, vice president of Energy and Charging at Tesla, stated that the launch of the Shanghai Megafactory for energy storage will ramp up production this quarter, helping Tesla expand into more markets.

What are the steps in energy storage installation?

The main steps are: to build the foundation, install the energy storage cabinets, install the battery and inverter, and wire it all. During the commissioning of an energy storage system, which tests does the team perform? System-wide joint commissioning.

What are the sections of energy storage project guide?

The guide is divided into three main sections: construction and installation, commissioning, and operation & maintenance. It covers various aspects such as foundation construction, battery and inverter installation, wiring, system testing, monitoring, fault handling, and preventive maintenance. 1. Energy Storage Project Construction 2.

What is energy storage platform & how does it work?

The platform connects global energy storage projects for intelligent O&M. It allows monitoring of project operations and battery performance. The platform gathers data to maximize its value, aiding in optimizing designs and extending service life.

Industry Information

- Large-capacity energy storage batteries in East Africa

- Asmara energy storage equipment box manufacturer

- Rabat station-type energy storage system function

- Photovoltaic solar panels in rural Gomel Belarus

- Rwanda Energy Storage Container Factory 125kWh

- Price comparison of Thimphu grid-connected inverters

- UPS uninterruptible power supply laid flat

- 1500w solar inverter in China in Iraq

- Multifunctional communication base station wind and solar complementary production enterprise

- Czech solar photovoltaic tile supplier

- Price and lifespan of photovoltaic panels

- Tskhinvali outdoor power supply installation

- China 1 5 kva hybrid inverter in Sudan

- Battery energy storage system and maintenance of communication base stations

- How much does a monocrystalline photovoltaic panel cost in Sydney Australia

- Investment returns of wind power with energy storage

- Outdoor power cabinet manufacturer in Porto Portugal

- Solar power generation systems are available for sale in South Sudan

- How to make a container generator set

- Huawei outdoor power mobile equipment

- Inverter 24v to 220v price

- Bahrain photovoltaic panel manufacturer

- Berlin quality battery cabinet retail

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.