High power T-type-based multi-level inverter for electric

Nov 1, 2023 · This paper presents an extension of a 5-level T-Type inverter to a high-power multi-level inverter that can be implemented in electric vehicles and trucks. The proposed inverter

Capacitors for High Power

Mar 21, 2024 · The DC-link capacitor''s purpose is to provide a more stable DC voltage, limiting fluctuations as the inverter sporadically demands heavy current. A design can use different

Insulation & Protection Materials for Capacitors

Mar 17, 2021 · The capacitor market is complex, with many product geometries, designs, properties and applications. New technologies and the demand for improved productivity

Realization of an extended switched-capacitor multilevel inverter

Oct 1, 2023 · In this paper, the basic unit of a new switched-capacitor (SC) topology is extended to achieve higher voltage levels with fewer components. The capacitors are charged from the

High Voltage Capacitor and Power Supply Applications

Simulators can mimic different types of lightning strikes such as high voltage, high current, multi stroke, and multiple burst type strikes. Yag Laser A Yag laser is a solid state laser made of

Impact of the non-ideal condition in the analysis of high voltage

May 12, 2025 · In addition, by considering the voltage balance law the equations of Table 2 and the maximum dc link voltage in the nST mode, the average voltage of the capacitors and the

Y Capacitor: The Comprehensive Guide

4 days ago · A capacitor with a different voltage rating, capacitance, or safety certification might not perform adequately or safely. Overlooking End-of-Life

A NEW HYBRID ACTIVE NEUTRAL POINT CLAMPED

Sep 2, 2016 · 1. INTRODUCTION Multilevel inverters have gained interest during the last three decades due to the increasing demand for medium to high voltage converters for a variety of

A Switched-Capacitor Based Multilevel Inverter with

4 days ago · Switched capacitor inverters are composed of several switched capacitor units, voltage sources and semiconductors. In these topologies, voltages of capacitors are balanced

(PDF) A Review on Multilevel Inverter Topologies

Feb 1, 2022 · In this paper, a brief review of the multilevel inverter (MLI) topologies is presented. The two-level Voltage Source Inverter (VSI) requires

Demystifying high-voltage power electronics for solar

Apr 1, 2023 · One of the key subsystems in PV generation is the inverter. Advancements in high-voltage power electronics are resulting in more intelligent, more lossless and smaller PV

Multilevel inverters: an enabling technology

Jan 1, 2018 · Multilevel inverter is structured such that no voltage-sharing problems are encountered by the active devices. Some of the applications these inverters come under the

An eleven level single source switched capacitor boost inverter

2 days ago · The proposed structure, which consists of a single voltage source, 10 power electronic switches, 3 capacitors, and one diode, generates an 11-level stepped voltage

Review of Multilevel Level Inverter Using Different

May 3, 2024 · Abstract This paper provides a concise overview of various multilevel inverter (MLI) topologies. The conventional two-level Voltage Source Inverter (VSI) necessitates a filter to

multilevel inverters introduction types

Multilevel inverters are the choice of industry for high-voltage and high-power applications. Multilevel inverter technology is emerging recently as a very

Ultimate Guide to High Voltage Capacitors:

Jan 30, 2025 · Explore the world of high voltage capacitors, their various types, key applications in power systems, safety considerations, and how they are

Reveal the function and type of inverter capacitor –

Jan 17, 2024 · Voltage regulation: Inverter capacitor assist in maintaining a consistent voltage level, preventing fluctuations that could potentially harm connected devices. Energy storage:

An Overview of Different Multi-level Inverters

Jul 27, 2016 · Demand for high-voltage, high-power converters capable of producing high-quality waveforms while utilizing low voltage devices and reduced switching frequencies has led to

The Roles of Capacitors in EV Traction Inverter

Dec 13, 2023 · There are many different types of capacitors that ensure the efficient and effective operation of your traction inverter. Here are the main

Design Capacitors for Applications | DigiKey

May 13, 2016 · The importance of dielectric materials, ESR, ripple current and other parameters when selecting DC link capacitors for maximum performance in DC link circuits.

Comparison Study and Simulation of the Main Multilevel Inverter

This paper compares between four different topologies of cascaded H-bridge multilevel inverter. Inverter can be defined as a power electronic device which can convert dc to ac at specified

The Roles of Capacitors in EV Inverters

Jul 31, 2024 · There are many different types of capacitors that ensure the efficient and effective operation of your traction inverter. Here are the main

Advantages and disadvantages of different types

Download Table | Advantages and disadvantages of different types of multilevel converters from publication: Reduced DC voltage source flying capacitor

What are Flying Capacitors?

Mar 15, 2023 · As demand for high-efficiency and high-power-density inverters continues to grow, the so-called "flying" capacitor multilevel inverter is

TECHNICAL PAPER

May 19, 2025 · Electric vehicles (EVs) have accelerated the demand for high-performance, high-reliability capacitor technologies. The wide array of voltage, power, and size requirements of

Modular Capacitors Smooth Out Power from High-Voltage

Oct 24, 2024 · TDK focuses on flexibility with xEVCap, its new modular DC-link capacitor solution for EV traction inverters.

Selecting and Applying DC Link Bus Capacitors for

May 16, 2023 · Sam G. Parler, Jr., P.E. Cornell Dubilier Abstract, aluminum electrolytic and DC film capacitors are widely used in all types of inverter power systems, from variable-speed

Flying Capacitors Explained

Apr 2, 2025 · As demand for high-efficiency and high-power-density inverters continues to grow, the so-called "flying" capacitor multilevel inverter is

The Roles of Capacitors in EV Inverters

Jul 31, 2024 · The Role of Capacitors in EV Traction Inverter Application There are many different types of capacitors that ensure the efficient and effective

Selecting Capacitors for Inverter Applications

This paper will present a practical mathematical approach on how to properly size a bus link capacitor for a high performance hard switched DC to AC inverter using film capacitors and will

(PDF) Multilevel Inverter: A Survey on Classical

Sep 14, 2021 · medium voltage range due to the semiconductor ''s blockage voltage limitation. However, MLIs play a key role in medium-voltage and high

Inverter DC Link Capacitor Selection

Sep 10, 2019 · Properly sizing the DC link capacitor for a three phase inverter seems to be a skill that evades most power electronic engineers. The

A Review Analysis of Switched-Capacitor-based Inverters with Different

Aug 6, 2022 · This paper presents a comprehensive review of some recently proposed switched-capacitor based boosting multilevel inverters. Reduced component count, self-volta

Film Capacitors Characteristics and Uses in

Aug 12, 2022 · This paper describes the different types of capacitors that might be considered for use in power electronics applications. Particularly, electrolytic

Voltage Inverter : Circuit, Working and Its

Mar 30, 2019 · Most inverters are of the variable voltage, variable frequency design. They consist of a converter section, a bus capacitor section and an

Capacitor Technologies in EV Power Systems

May 9, 2024 · Let''s now look at some of the common applications where capacitors are required inside the EV, the different jobs capacitors must take

6 FAQs about [Are the high voltage capacitors of the inverter different ]

What is a capacitor in an inverter?

The primary function of a capacitor in an inverter is to manage and optimize the flow of electrical energy. Key roles include: Voltage regulation: Inverter capacitor assist in maintaining a consistent voltage level, preventing fluctuations that could potentially harm connected devices.

What are the different types of capacitors for traction inverters?

There are many different types of capacitors that ensure the efficient and effective operation of your traction inverter. Here are the main players: Snubber Capacitors – Voltage suppression is important to protect circuits from large voltage spikes.

Why should you use an inverter capacitor?

Voltage regulation: Inverter capacitor assist in maintaining a consistent voltage level, preventing fluctuations that could potentially harm connected devices. Energy storage: Inverter capacitor store energy during periods of excess supply and release it during times of increased demand, contributing to a stable power output.

What happens if an inverter capacitor fails?

The failure of an inverter capacitor can have several consequences, including: Voltage fluctuations: Capacitor failure may lead to unregulated voltage, causing fluctuations that can damage connected devices. Overheating: A malfunctioning capacitor can overheat, posing a risk of fire or damage to surrounding components.

Which inverter capacitor should I Choose?

The choice ultimately hinges on the inverter's design, intended use, and performance demands. Ceramic dielectric capacitors are the most commonly used inverter capacitors because of their robustness, high capacity and fast response time.

Does Adding capacitance improve the performance of an inverter?

So beyond a certain point, adding capacitance does little to enhance the performance of the inverter. = 308 uF That’s 16 times less capacitance than that of the electrolytic capacitor! Certainly packaging a 308 uF capacitor verses a 5,000uF capacitor makes for a smaller, lighter and more compact design.

Industry Information

- Bridgetown double glass photovoltaic curtain wall supplier

- Microgrid Energy Storage Business Model

- Container outdoor power consumption

- Ultra-large energy storage commercial battery

- Portable energy storage 4kw

- How many inverters are needed for 600kw photovoltaic

- South Africa led 40 watt solar street light

- Battery cabinet rated power

- Industrial Park 5g Base Station Power Supply Environment Transformation

- Guyana Solar Water Pumps

- Is the battery cabinet a battery pack

- Ecuador solar tile manufacturer

- Charging and discharging time of energy storage battery

- 1000w solar inverter for sale in Finland

- Rwanda photovoltaic panel manufacturers

- 60v1300w inverter

- Solar powered house generator in Germany

- Villa photovoltaic energy storage system

- Dc380v inverter 220v

- Wind power system connection

- Bangladesh photovoltaic off-grid inverter

- High voltage inverter 1000kv

- Outdoor power supply changes pressure

Commercial & Industrial Solar Storage Market Growth

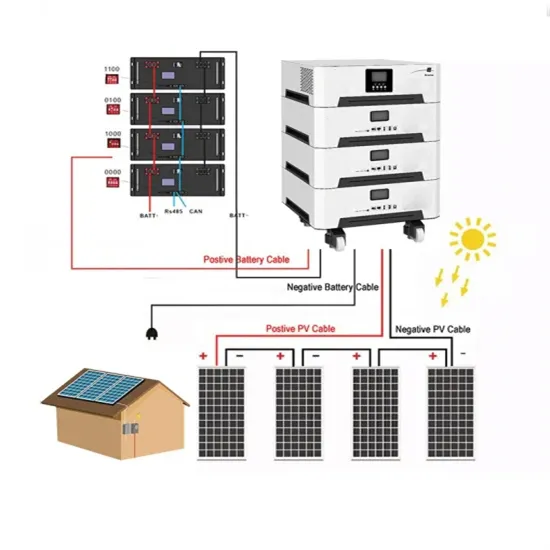

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.