How to Run a Ground Wire to an Electrical Panel

Jan 6, 2025 · This article will tell you how to run a ground wire to an electrical panel & the importance of doing this task.

How to Attach Wires to a Battery? (Full Process)

Oct 5, 2022 · How to Attach Wires to a Car Battery? Assuming you would like a blog post discussing how to connect wires to a car battery: Most cars have a

How To Properly Ground Your Server Rack

Jun 2, 2023 · How To Ground a Server Rack To ground a server rack, you can find contractors who will provide a network grounding system. When properly

Battery Ground Wires – Connected to Engine

Sep 17, 2021 · Car batteries are grounded to the body and chassis of the car, and the engine to use the car chassis and body as the return path for the circuits of

How To Ground A House Electrical System: A

Oct 22, 2023 · Dig a hole (about 8 feet deep) and place the rod inside, leaving about 6 inches above ground level. Step 3: Connect the grounding wire. Using

Am I supposed to ground the inverter or the

Jun 26, 2017 · I am setting up a solar system in a vehicle. I have 400W solar panels, a 12V battery bank, and a 2000W inverter. I''ve looked at the manuals

How to ground the energy storage cabinet

cabinet, you need to ground the cabinet. As an industry best practice, we recommend groundin a complete bonding and grounding system. The bonding wire is shown connecting the lid of the

How to Properly Ground a Car Battery

Apr 4, 2025 · To properly ground a car battery, you need to securely connect the negative terminal to a clean, unpainted metal surface on the vehicle''s chassis. Many car owners

Why connect a ground cable from cabinet to door of cabinet?

Jun 22, 2020 · You would not expect a cabinet door to be able to shock you, but if it had plastic hinges or paint on the metal hinges, it may not be automatically grounded. Thus the wire

Securely Connect Ground Wire to Car Battery: Safety Steps

Oct 15, 2024 · Learn the crucial steps to connect the ground wire to your car battery safely and efficiently. Discover the importance of protective gear, proper handling techniques, and

A Guide to Grounds, Earth, and Grounding

Jul 1, 2021 · Learn about the different types of earths and grounds, and how they apply to everyday electronic circuits.

Can the battery cabinet be installed with a ground wire

The interior perimeter ground loop consists of a 2 AWG bare copper ground wire connected to the signal reference ground (SRG) at every interior ground bar. Metallic parts entering the

Grounding Essentials: Where to Connect Your Ground Wire

Jun 8, 2025 · The Importance of Ground Wires Before diving into where to connect your ground wire, it''s essential to understand what a ground wire is and why it''s critical for your electrical

Earthing the battery cabinet

Jun 13, 2025 · Earth the battery management system during installation. Connect the supplied grounding cable to the battery cabinet grounding point (hexagon socket, AF13, torque: 8 Nm).

How to Connect Ground Wires Together (Guide)

Jun 15, 2022 · Ground wires are part of supplying the electricity in your home. This guide shows you how to connect the ground wires together.

importance of earthing a rack battery and its

Mar 18, 2023 · If you do connect, say the negative terminal of the battery to the case, and ground the case, you''ve now made a second electrical connection

Connecting UPS Grounds and Neutrals | EC&M

Oct 1, 2002 · For multiple battery cabinets incorporating battery disconnects, the cabinets are bolted together, forming a single lineup with the UPS. The

How to Properly Ground a Car Battery

Mar 9, 2023 · Ground Wire for Car Battery A ground wire for a car battery is an important component in the electrical system of any vehicle. It serves as a direct connection to the

How To Connect Wires To A Battery Terminal

Feb 12, 2025 · Learn how to safely connect wires to a battery terminal with this step-by-step guide. Prevent short circuits and ensure a secure connection.

Battery Cabinet

Feb 28, 2025 · Confirm that the charging source prior to connecting or disconnecting battery terminals has been disconnected or off line. Determine if battery is inadvertently grounded. If

How To Ground Electrical Enclosure: The

Sep 23, 2021 · Often, you land the incoming ground onto a backpanel-installed grounding terminal, bar, or lug. This connector links the ground conductor to

How to Ground an Electrical Panel: A Complete

May 29, 2025 · Learn how to ground an electrical panel step-by-step. Ensure safety, code compliance, and protect your home from electrical hazards.

No Place To Connect Ground Wire: Here Are A

Dec 24, 2021 · Found yourself with no place to connect ground wire? Worry no further! I have the solutions for you in this article. Read to find out what they are!

Practice for good grounding and bonding a

Jun 19, 2017 · Using a brass clamp commonly referred to as an acorn, connect the wire to the first ground rod, pulling the wire taut so no slack exists.

How to Connect Red and Black Wires to a Battery

Feb 5, 2025 · Learn how to safely connect red and black wires to a battery with step-by-step instructions and expert tips for proper wiring.

How to Safely Ground a Flammable Cabinet: Essential Steps

5 days ago · The wire can be wrapped around the rod or pipe and tightened using pliers or a wrench. Ground the Cabinet: Connect the other end of the grounding wire to the grounding

Grounding a Justrite Safety Cabinet | Justrite

For exterior cabinet grounding, locate the safety cabinet''s ground screw just below the green dot on the right hand side of the cabinet. Use a 5/16" (8 mm)

How To Connect Ground Wire To Car Battery

Jul 2, 2023 · Make sure the car battery is disconnected before attempting to connect the ground wire. Locate the ground wire, which is typically black and attached to the car''s chassis or

Where To Connect Ground Wire Of Car Battery:

Dec 10, 2024 · The ground wire of a car battery should be connected to an appropriate metallic chassis ground point, or in some cars, to an engine block

Correctly Earthing a Metal Enclosure | Electronics Forum

Jul 25, 2013 · Hi, I wanted to know the correct procedure for main earthing an electronics project built in a metal case, I live in the UK with the standard 3 pin wire configuration for live, neutral

Connecting the Ground Cable to the Cabinet/Rack

Use a Phillips screwdriver to secure the M6 lug of the ground cable to the ground point with an M6 screw. Tighten the M6 screw with a torque of 4.8 N m. After the ground cable is connected,

6 FAQs about [How to connect the ground wire of the battery cabinet shelf]

How to ground a metal enclosure cabinet?

Moreover, it will include the hardware that you will use for grounding all the metallic components of the enclosure cabinet. The hardware may comprise of distinct ground sign sticker, which you need to place at every connection point. Often, you land the incoming ground onto a backpanel-installed grounding terminal, bar, or lug.

How do you ground an electrical enclosure?

Often, you land the incoming ground onto a backpanel-installed grounding terminal, bar, or lug. This connector links the ground conductor to enclosure backpanel. Backpanels are usually mounted using machine screws or nuts and star washers to make sure they are attached to the metal electrical enclosure. Electrical Enclosure Grounding

What is a grounded electrical enclosure?

Grounded Electrical Enclosure The electrical system components are linked to the earth ground by a grounding bar within the electrical enclosure. In case an electrical fault happens, like ground fault or short circuit, the ground acts as safety feature guard against associated hazards.

How do you ground a control panel enclosure?

You should list all the electrical connector hardware used in control panel enclosure grounding. Some of the usual termination ways for ground wires include: Grounding Lug: The fitting features a compression section that receives the incoming cable. There is a hole enabling you to bolt it to an appropriate backpanel or enclosure stud.

Do electrical control panel enclosures need a fixed grounding system?

Manufacturers on occasions recommend “isolated ground.” Nevertheless, majority of electrical enclosures need not to feature their entirely independent grounding system fixed. A correctly fixed star grounding system offers a safe and dependable electrical control panel enclosure installation.

Why is proper electrical enclosure grounding important?

Proper electrical enclosure grounding is a vital facet for providing safety, performance and uptime. However, it is always easy to overlook grounding aspects, or to fix them incorrectly. Often, the electrical enclosure will perform as usual with incorrect grounding, though will result in a danger if a fault happens.

Industry Information

- Baghdad Communication Base Station Battery 100KWh

- Small solar inverter for sale in America

- Nicaragua energy storage battery pump

- Sri Lanka has several energy storage power station companies

- Prerequisites for investing in energy storage power stations

- Pure sine wave 220 to 24v inverter

- China molded circuit breaker in Suriname

- How much voltage do 9 inverters have

- Customization of container energy storage system on Bhutan streets

- Ranking of London photovoltaic container manufacturers

- How much does a photovoltaic energy storage machine cost

- 10 billion yuan subsidy for outdoor power supply

- Which is the best super farad capacitor in Cordoba Argentina

- China hybrid inverter on grid in Armenia

- Solar power supply system in Manchester UK

- Which is better solar power or energy storage power generation

- Major manufacturers of outdoor power supplies

- Khartoum Communication Photovoltaic Base Station Tower

- Mobile base station equipment solar panel industry standards

- Photovoltaic glass warping

- How to connect the ground wire of the battery cabinet shelf

- Lithium battery station cabinet manufacturers

- High quality China drawout circuit breaker supplier

Commercial & Industrial Solar Storage Market Growth

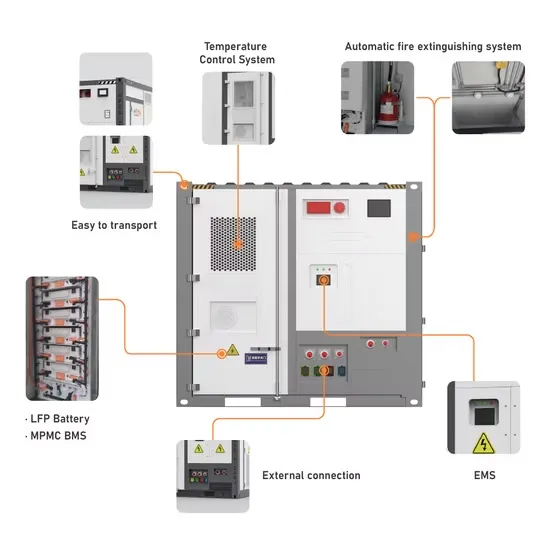

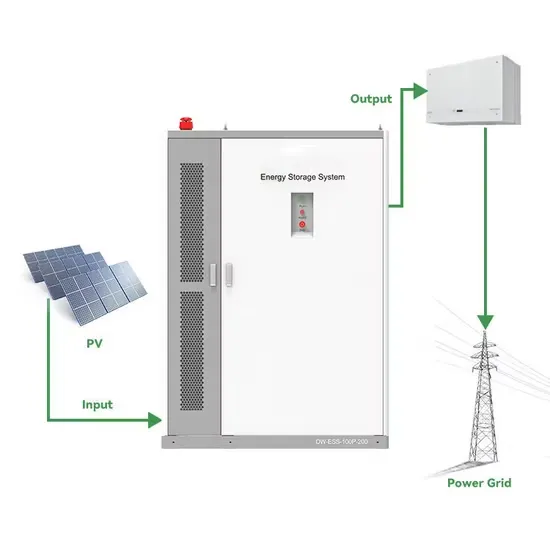

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.