Powerware 9395 Integrated Battery Cabinet (Model IBC

Jun 17, 2016 · Battery Cabinet (IBC) systems are housed in single free-standing cabinets. Model IBC-L with a ingle battery voltage range is available to meet application runtime nee s. Up to

Where can the battery system be installed? What are the electrical

Should be installed within 20 feet of the electrical meter. Conduit runs from the battery to the meter, and Base cannot perform any trenching or attic conduit runs.

BATTERY CABINETS CATALOGUE

Jun 4, 2025 · GENERALITY The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries. The construction

Choosing the Right Battery Storage Cabinet: A

Jun 5, 2025 · Lithium-ion batteries have become indispensable across countless industries, from logistics and warehousing to construction and renewable

12 Types of Electrical Boxes and How to Choose

Aug 28, 2024 · Learn about the many common types of wall and ceiling electrical boxes for switches, outlets, light fixtures, ceiling fans, and junction boxes.

Powerware 9395 Integrated Battery Cabinet (Model IBC

Jun 17, 2016 · The term standalone refers to battery cabinets that may be installed adjacent to the UPS or in a separate location, are wired with external customer-supplied conduit and wiring,

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · For instance, if a battery, rack and charger are required the system can be designed using a 2 step rack with the charger mounted above, or with a 2-tier rack with the

Battery Cabinet

Feb 28, 2025 · Atlantic Battery Systems believes that, with the safety features built into the cabinets, qualified experienced personnel should not be exposed to undue electrical hazards

Galaxy Lithium-ion Battery Cabinet

Jan 2, 2025 · Read these instructions carefully and look at the equipment to become familiar with it before trying to install, operate, service or maintain it. The following safety messages may

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

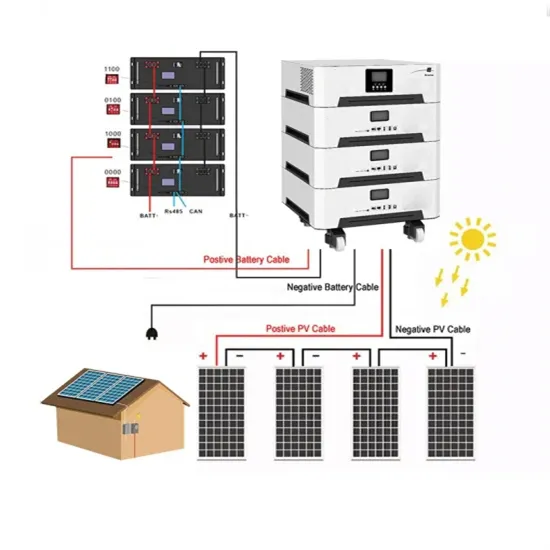

How to correctly install lithium battery energy

Mar 25, 2024 · Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid auxiliary services

EV chargers installed direct to meter box

Dec 29, 2023 · , EV chargers installed direct to meter box - is it really wrong?, Electric Vehicles Advice Forum, ElectriciansForums Est.2006 | Free

Galaxy Lithium-ion Battery Cabinet

Schneider Electric does not grant any right or license for commercial use of the guide or its content, except for a non-exclusive and personal license to consult it on an "as is" basis.

Galaxy VS

Mar 19, 2021 · Schneider Electric does not grant any right or license for commercial use of the guide or its content, except for a non-exclusive and personal license to consult it on an "as is"

Practical considerations when designing a battery room

Jul 27, 2018 · Fuse Box and Breaker Points: Some national legislation and electrical company regulations will demand a voltage cut-off breaker next to the battery. If no other option is

The Best Placement For Electrical Boxes In Kitchen Cabinets

Apr 21, 2025 · Electrical box placement for cooktops and ovens When it comes to electrical box placement for cooktops and ovens, there are a few important considerations to keep in mind.

National Electrical Code (NEC) Requirements for

1 day ago · The National Electrical Code (NEC) provides comprehensive safety standards for electrical installations, including requirements for electrical

Guidelines for Current Transformer (CT) installation

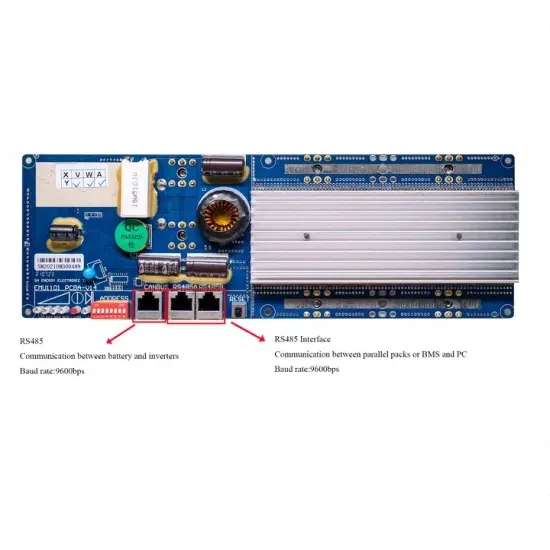

Figure 3: Current transformer installation for grid-tied PV+IQ Battery sites NOTE: For sites with IQ Gateway installed instead of IQ Combiner, the Production CT and IQ Battery CT should be

Installation Procedure

Follow the battery cabinet installation manual to: Prepare the battery cabinet for installation. Install seismic anchoring (if applicable). Position and interconnect the battery cabinet (s). Prepare the

480.9 Battery Locations.

2014 Code Language including the Errata: 480.9 Battery Locations. Battery locations shall conform to 480.9 (A), (B), and (C). (A) Ventilation. Provisions

Choosing the Right Lithium Ion Battery Cabinet:

May 1, 2025 · Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and

Galaxy Lithium-ion Battery Cabinet

Jan 2, 2025 · Electrical equipment should only be installed, operated, serviced, and maintained by qualified personnel. No responsibility is assumed by Schneider Electric for any consequences

Considerations For Battery Room Design, Battery Stands and

This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a safe environment. Alternative battery stand types are discussed to

Considerations For Battery Room Design, Battery Stands and

Batteries may be mounted on racks or in cabinets. When installed on racks, these may be of wood or steel and both may be insulated from earth. Generally speaking, battery stands are

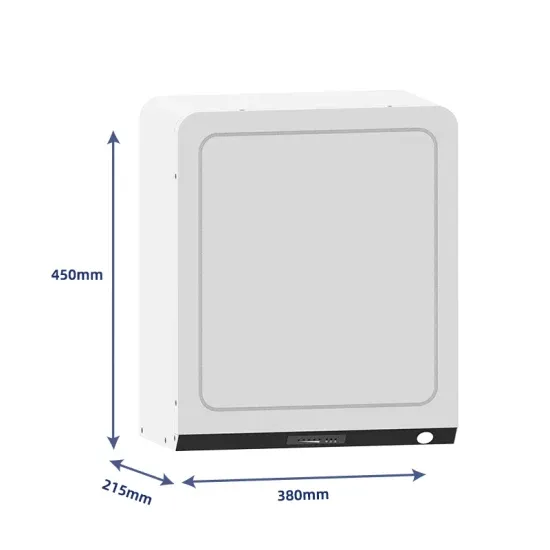

Key Considerations for Installing a Lithium Battery Cabinet

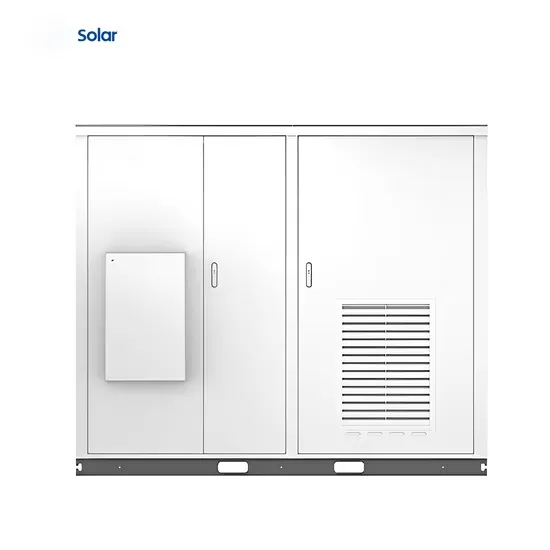

The V-BOX-OC is designed to be installed on a stable and properly grounded surface to maximize its performance and longevity. Electrical Infrastructure The site must have the necessary

Easy UPS Modular Battery Cabinet

Sep 18, 2020 · Schneider Electric does not grant any right or license for commercial use of the guide or its content, except for a non-exclusive and personal license to consult it on an "as is"

Connect the Power Cables

If more battery cabinets are part of the solution, connect all battery cabinets to the UPS according to the diagram below. NOTE: If the combined short circuit current of the battery cabinets

How to Design a Telecommunication Battery

Nov 30, 2021 · 2. How to determine the size of the battery cabinet? What kind of structure should it adopt? Battery cabinet size is based on the application

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

164201687_1085_Rev_4_Web

Feb 28, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Model 1085 or 1085HR with a single battery voltage range is available to meet

Electricians'' preferred elec. box placement for

Sep 20, 2017 · Electrical - AC & DC - Electricians'' preferred elec. box placement for cooktops & ovens - I''ve gutted my kitchen including removing all drywall

Battery Room Design Requirements –

It does not cover maintenance free or computer room type batteries and battery cabinets. Main keywords for this article are Battery Room Design

Key Considerations for Installing a Lithium Battery Cabinet

Lithium battery cabinets must be installed in environments that do not exceed certain temperature and humidity thresholds. The V-BOX-OC is designed to withstand a range of conditions, but

Guidance on installing equipment within meter

Sep 18, 2023 · The experts at NICEIC provide more detail on the installation of equipment in meter boxes. Electrical equipment associated with the

Electrical Outlets in Cabinetry

Question We do mainly built-ins. Wall units, entertainment centers, and such. Backs have about 1/2" gap from drywall. What''s the best way to mount an outlet inside a cabinet or on the back

Analysing Battery Cabinet and Battery Racks

Apr 29, 2022 · For quite a time, there have been talks on whether the battery should be installed or cabinets or on racks. Both these options have their advantages as well as disadvantages

6 FAQs about [Should the electric box be installed in the battery cabinet ]

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

What rating should a battery cabinet have?

Indoor battery cabinet should have at least NEMA 1 rating. On the other hand, outdoor enclosures for batteries should have a NEMA 3R rating. It is important to note that the NEMA and IP rating varies depending on where you will install the enclosure. Indoor Battery Box Enclosure 2. Mounting Mechanism for Battery Cabinet

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

How do you choose a battery cabinet?

Again, the door should have a safe locking mechanism or latch. In more advanced battery cabinets, they may have alarm systems. Ventilation systems – they may integrate louvers. Depending on the enclosure design, the ventilation systems can be at the top or bottom section. Ventilation systems also help during the cooling process.

What is a battery cabinet?

The battery cabinet is designed for industrial or computer room applications and should be handled with appropriate care. This battery cabinet contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS

Industry Information

- How many watts can a solar air conditioner produce

- PV inverter efficiency and temperature

- The role of large mobile energy storage vehicles in Niger

- Lde solar light for home use

- The difference between energy storage and new energy storage

- Factory price of battery cabinet in Bandar Seri Begawan

- Algiers Portable Power Company

- What are cheap outdoor power supplies good for

- Latest Tool Batteries

- PD mobile power portable energy storage power supply

- Doha Outdoor Energy Storage

- Three-phase inverter closed-loop control

- Saint Lucia cabinet energy storage system price

- Base station battery output power

- Energy storage battery can discharge

- China circuit breaker fuse for sale producer

- Thailand 5G communication base station supercapacitor project

- 53v with 48v inverter

- Swaziland Distributed Energy Storage Cabinet Customized Manufacturer

- Household solar lights in rural areas

- San Marino 24 strings inverter 220v

- Lithuanian monocrystalline double-glass modules

- Tajikistan Steel Enterprise Energy Storage Project

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.