Can You Mix Different Capacity Lithium

Jun 20, 2023 · A comprehensive guide to mixing different capacity lithium batteries. Dive into the crucial aspects of voltage, BMS, fuses, and more.

Understanding Li-Ion Battery Packs: A Complete Guide

Aug 8, 2024 · Explore Li-ion battery packs in detail, from their chemistry and composition to benefits and customization options with Ufine.

A Novel Active Cell Balancing Approach Based on

Oct 2, 2024 · In recent years, the advancements in deep reinforcement learning (DRL) have made it a viable tool for battery management systems (BMS) in EV''s. In this research paper, a new

BU-302: Series and Parallel Battery Configurations

Some packs may consist of a combination of series and parallel connections. Laptop batteries commonly have four 3.6V Li-ion cells in series to achieve a

Understanding Four-Wire Lithium Battery Packs Design

Why Four-Wire Lithium Battery Packs Matter Today Lithium battery packs with four-wire configurations have become essential in high-precision applications. Unlike traditional two-wire

LITHIUM‐ION BATTERY MANUFACTURING FOR ELECTRIC

Oct 3, 2016 · Abstract Battery electric vehicles (BEVs) fall into one of the following four categories: hybrid electric vehicle (HEV), plug-in electric vehicle (PHEV), extended range electric vehicle

A review on thermal management of battery packs for

Feb 1, 2024 · The first part of the paper contains a brief outlook on battery technology and its modality of discharge and charge. In the second part, the problem of the thermal management

The Handbook of Lithium-Ion

Aug 16, 2025 · In a Chapter I wrote for the Handbook of Lithium-ion Battery Applications(Warner, 2014), I offered a brief look at Li-ion battery design considerations and discussed cells,

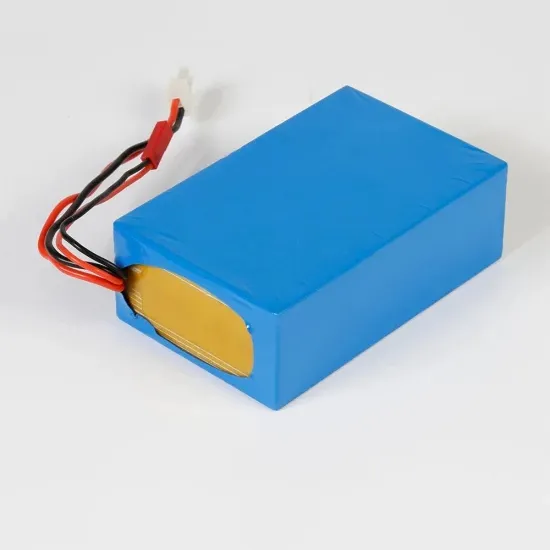

Lithium-Ion Battery Packs | Electronic

Lithium-Ion Battery Packs A battery pack is a set of any number of battery cells connected and bound together to form a single unit with a specific

A cell level design and analysis of lithium-ion battery packs

Oct 31, 2024 · Rechargeable batteries are studied well in the present technological paradigm. The current investigation model simulates a Li-ion battery cell and a battery pack using COMSOL

Reinforcement learning for battery energy management: A

Sep 1, 2024 · The aim of this research is to achieve a more efficient and adaptive battery management system for lithium-ion battery packs using switched passive shunt resistors and

An integrated cell-to-pack design based on an origami

Apr 1, 2024 · In this work, three-dimensional (3D) thermal modeling of a single Li-ion battery cell and a 50 V Li-ion battery pack composed of 14 prismatic batteries is performed.

How to Assemble a Lithium-Ion Battery Pack

Oct 7, 2024 · Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

How to Balance Lithium Batteries in Parallel

Sep 26, 2023 · If you are building a battery bank with multiple batteries in parallel getting and keeping them in balance is crucial to the overall health of the bank.

Thermal runaway and flame propagation of lithium-ion battery

May 1, 2025 · The thermal safety of lithium-ion batteries (LIBs) in confined spaces remains a critical challenge in power battery pack design. This study conducts a

How to Connect 4 Batteries in Series

Dec 13, 2023 · Learn how to connect 4 batteries in series for optimal power output and efficiency with our easy-to-follow step-by-step guide.

ENHANCEMENT ON THE THERMAL BEHAVIOR USING

Apr 1, 2022 · In the present study, the thermal behavior of a power battery cooling structure em-ploying copper rods, and heat pipes was compared. The influences of flow rate and inlet

A Beginner''s Guide To Lithium Rechargeable

Jun 11, 2020 · Lithium-ion, or Li-ion typically refers to the overarching technology of rechargeable lithium batteries, but also specifically refers to the traditional

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · Lithium Series, Parallel and Series and Parallel Connections Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by

Model-Based Design of an Electric Bus Lithium-Ion Battery Pack

Mar 18, 2021 · Abstract. This study details a framework for an iterative process which is utilized to optimize lithium-ion battery (LIB) pack design. This is accomplished through the

Lithium Ion Battery Pack: How is it made?

Jul 26, 2021 · Figure 1 Expansion in demand for Lithium-Ion batteries, GWh – Gigawatt hours (Deng, 2015) A complete battery pack is made up of the

Life prediction of large lithium-ion battery packs with active

May 26, 2017 · Lithium-ion battery packs take a major part of large-scale stationary energy storage systems. One challenge in reducing battery pack cost is to reduce pack size without

Lithium-ion battery thermal management for electric

Dec 1, 2023 · Abstract Lithium-ion (Li-ion) batteries in electric vehicles (EVs) present a promising solution to energy and environmental challenges. These batteries offer numerous advantages,

Configurations of the four battery packs.

Configurations of the four battery packs. [...] Lithium-ion batteries are widely used in the energy field due to their high efficiency and clean characteristics. They...

Design of Controlled Charging Strategy for Parallel

Nov 25, 2022 · A recent trend in electric vehicles has been to utilize larger battery capacity to provide a higher driving range. The conventional battery pack connection empl.

Full-scale experimental study on suppressing lithium-ion battery

May 1, 2022 · The battery packs used in EVs consist of a large number of single cells that are connected in series and parallel modes. If a cell in the battery pack is triggered into TR, it may

Connecting (And Using) High-Capacity Batteries

May 27, 2024 · The problem with using different battery packs in parallel is that unless the batteries are charged to similar voltages, they could generate a

What Is A Lithium-Ion Battery Cell, Module, and

Jan 30, 2024 · We will delve into the components that make up a lithium-ion battery system, exploring the differences of battery cells, battery modules, and

A review of international abuse testing standards and regulations

Jan 1, 2018 · This comprehensive review aims at presenting the various international standards and regulations for safety testing of lithium ion batteries in automotive applications under

Thermal runaway and propagation characteristics of sodium

To bridge this research gap, the present study constructs three types of pure battery packs (LFP, NCM, and SIB) and five distinct sodium–lithium hybrid configurations (AB1–AB5) using uniform

Introduction to battery pack design and

Most garage-builders who decide to assemble their own battery pack usually have a lot of experience. However, pack-building continues to be a frequent

Charging LiFePO4 Batteries In Parallel And Series

Oct 7, 2023 · In conclusion, you must have got all the information around lithium batteries and charging lithium phosphate batteries in parallel and series. While

Battery Spot Welder: Guide for Lithium Battery

May 24, 2024 · Learn how to use a battery spot welder for lithium packs, with tips on equipment, techniques, and ensuring strong, safe welds.

439747_1_En_8_Chapter 175..200

Feb 10, 2018 · Current Li-ion battery packs are prone to failure due to reasons such as continuous transmission of mechanical vibrations, exposure to high impact forces and, thermal runaway.

Study of the Characteristics of Battery Packs in Electric

Jan 11, 2018 · Abstract—This paper studies the characteristics of battery packs with parallel-connected lithium-ion battery (LiB) cells. To investigate the influence of the cell inconsistency

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous

Model-Based Design of an Electric Bus Lithium-Ion Battery Pack

Mar 18, 2021 · In recent years, electric vehicles (EVs) are becoming more common and are utilizing higher capacity lithium-ion battery (LIB) packs on road ways around the world. These

Understanding Four-Wire Lithium Battery Packs Design

Four-wire lithium battery packs offer unmatched accuracy for mission-critical applications. As renewable energy and EVs keep growing, understanding this technology becomes crucial.

6 FAQs about [Four lithium battery packs in one rod]

How many cells are in a lithium-ion battery pack?

The method undergoes a real-world electric vehicle testing with 276 cells. The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous cells in parallel or series within the packs.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

Is there a standard size lithium-ion battery pack?

Perhaps the first and most important statement we can make about battery packaging is this: there is no standard size lithium-ion battery pack and there is not likely to be one in the near future.

Are lithium-ion batteries a viable energy storage solution?

URRENTLY, lithium-ion batteries (LiBs) are considered as one of the major viable energy-storage solutions for electric vehicles (EVs) and plug-in hybrid EVs (PHEVs). The battery pack provides power and energy to drive the vehicle, as shown in Fig. 1. Typically, the power demands can be up to 30–120 kW.

What are lithium-ion batteries?

1. Introduction Lithium-ion batteries (LIBs), as the most preeminent commercialized energy storage devices, have achieved widespread adoption in portable electronics, electric vehicles (EVs), and large-scale energy storage systems [, , ].

Which battery cells are used in a CMB battery pack?

CMB’s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate Chemistry) and LiPo (Lithium Polymer).

Industry Information

- China al hassan switchgear for sale Wholesaler

- Best breaker distribution in China Seller

- Santo Domingo Energy Storage Charging Station

- Haiti Solar Photovoltaic Folding Container Liquid Cooling

- Valletta Solar Application System Integration

- Is a 60-watt solar panel enough

- Which one requires more investment energy storage or photovoltaics

- Should small communication base station wind power be built at high places

- Cameroon energy storage lithium battery professional manufacturer

- Middle East outdoor power supply recommendation

- Serbia professional custom lithium battery pack

- Are there any communication base stations near the building that have hybrid energy

- Station-level energy storage fire protection solution

- Best bess system for solar factory Factory

- Sucre Communication Base Station Energy Storage Cabinet in stock

- Solid state breaker in China in Paraguay

- Can Yemen s outdoor power supply pass customs

- Price of photovoltaic tiles 130 square meters

- Photovoltaic combiner box

- Energy storage power supply 3-5 kilowatts

- Motorhome 12v inverter to 220v battery

- Wind power electrical access system

- Praia photovoltaic container customization

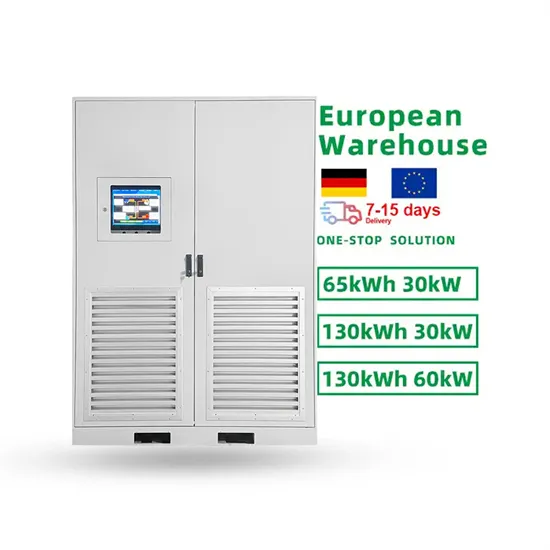

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

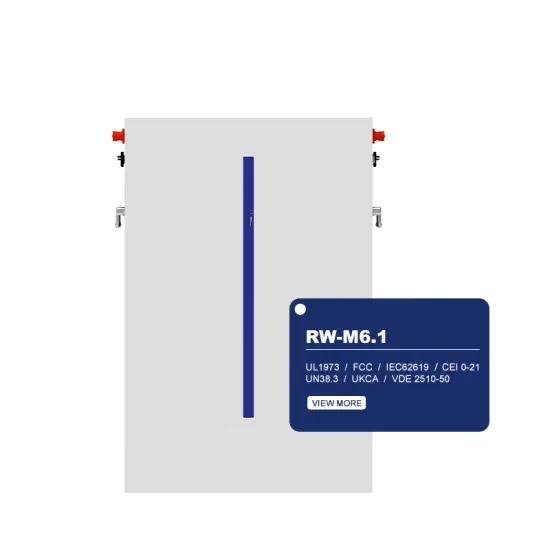

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.