Cylindrical Cell manufacturing line

Apr 11, 2025 · A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries. It combines specialized machinery, automation

Whole line solution for cylindrical Li battery cell

Domestic leading flight welding technology: the turntable is equipped with welding head 0.21rad/s speed online welding, power: 1.2kw, welding area: 64mm², welding layers: ≥8 layers, the pole

Lithium Cylindrical

5 days ago · Lithium Cylindrical VARTA Lithium Cylindrical are professional lithium round cells with long-lasting, supreme performance. Designed to withstand extreme temperatures while

Cylindrical

LiPol is a battery company that combines quality, safety, price and delivery time. Our cylindrical lithium polymer batteries show the actual rated capacity that

Analysis of cylindrical lithium battery advantages

Feb 6, 2023 · According to the data shown by Tesla, the 4680 large cylindrical lithium battery will increase the energy by 5 times on the basis of the 21700

A Quick Guide to Lithium-Ion Battery Sizes and

Apr 27, 2025 · Understand lithium-ion battery sizes like 18650, 14500, and pouch cells, and their applications in gadgets, EVs, and energy storage systems in

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

Room-temperature cylindrical lithium battery enabled by

Jun 1, 2025 · Cylindrical batteries have been explored as promising grid energy storage device, due to their high safety margin and low capital/maintenance costs. However, the practical

Whole line solution for cylindrical Li battery cell

Product description The assembly line mainly realizes a total of more than 10 technological processes from butt coating, winding to battery positive pressure helium detection and

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Analysis of Cylindrical Lithium Battery Advantages and

1. Definition of cylindrical lithium battery Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical

Cylindrical Lithium Battery Production Line

A cylindrical lithium battery production line is a highly automated and sophisticated system designed to produce high-quality batteries efficiently and

A Quick Guide to Lithium-Ion Battery Sizes and Uses in 2025

Understand lithium-ion battery sizes like 18650, 14500, and pouch cells, and their applications in gadgets, EVs, and energy storage systems in 2025.

How to enable large format 4680 cylindrical lithium-ion batteries

Nov 1, 2023 · The demand for large format lithium-ion batteries is increasing, because they can be integrated and controlled easier at a system level. However, increasing the size leads to

The advantages of cylinder battery vs square

Aug 17, 2025 · With the advancement in the reliable power sector, it is worth considering battery options. The most common form of battery packaging is

Complete Guide to Lithium Battery Models:

Jul 21, 2025 · With the continuous advancement of technology, lithium batteries have become a highly efficient and reliable power source for a wide range of

Cylindrical Lithium Battery Production Line

The production line for cylindrical lithium batteries is a complex and highly automated process designed to ensure high efficiency, quality, and

Room-temperature cylindrical lithium battery enabled by

Jun 1, 2025 · Herein, we report a sulfide-based cylindrical battery with a significantly reduced operating temperature of 30 °C, enabled by a sulfide solid electrolyte tube, a liquid lithium

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium-ion cells are usually represented by five digits unting from the left,the first and second digits refer to the diameter of

Cylindrical Battery Types and Sizes

Jun 3, 2024 · The most popular type of rechargeable cylindrical battery is the lithium-ion (Li-ion) battery. Li-ion batteries offer high energy density, low self

Turntable jig device of cylindrical lithium battery production

The invention belongs to the field of turntable jigs, particularly relates to a turntable jig device of cylindrical lithium battery production equipment, which aims to solve the problems that an

Prismatic vs Pouch vs Cylindrical Lithium Ion

Mar 11, 2025 · Prismatic vs Pouch vs Cylindrical Lithium Ion Battery Cell – Who Reigns Supreme? In the era of new energy, lithium batteries serve as core

Could Cylindrical Batteries Become Standard for

Mar 25, 2024 · Cylindrical batteries power the Tesla electric vehicle. Image used courtesy of Pexels 18650 Cylindrical Batteries Among the types of lithium-ion

18650, 21700, 30700, 4680 and other Li-ions

Sep 1, 2021 · Various cylindrical Li-ion batteries are offered in protected and unprotected packaging. Most electronic equipment, electric vehicles, and

Complete List of Cylindrical Lithium Battery Models.

Cylindrical lithium-ion batteries are usually represented by five digits. Starting from the left, the first and second digits refer to the battery diameter, the third and fourth digits refer to the battery

Everything about Cylindrical Batteries, the Power

May 29, 2024 · The importance of cylindrical batteries is only growing because they are used widely from small electronic devices to EVs. In line with the

Novel hybrid thermal management system for cylindrical lithium

Aug 15, 2025 · Abstract Heat dissipation issues, particularly at high discharge rates, constrain the safe use of Li-ion batteries, making effective thermal management essential. This study

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cellCylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

How to Choose a Cylindrical Lithium Battery

Dec 17, 2024 · What are the key characteristics of cylindrical lithium batteries? Cylindrical lithium batteries feature a robust cylindrical design, high energy density (300-500 Wh/kg), and long

Circular Battery vs Cylindrical Battery: Find the Right Fit

Feb 20, 2025 · Circular and cylindrical batteries differ in characteristics and applications. This article helps you choose the right one for optimal performance.

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

What Are the Lithium Ion Battery Sizes?

Jul 12, 2024 · Cylindrical lithium batteries are probably the most recognizable. They look a lot like AA batteries but come in various sizes and capacities.

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system batteries have different advantages, and the

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

The Ultimate Guide to Cylindrical Batteries

Mar 29, 2024 · Here we summarize the cylindrical battery types, capacity, voltage, etc., so you can have a more comprehensive understanding of

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cell Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

Cylindrical Cells

Aluminium Cell Housings for Cylindrical Lithium-ion Batteries Thermal simulations reveal significant improvements in cooling performance at 3C fast-charging of

6 FAQs about [Turntable cylindrical lithium battery]

What is a cylindrical lithium ion battery?

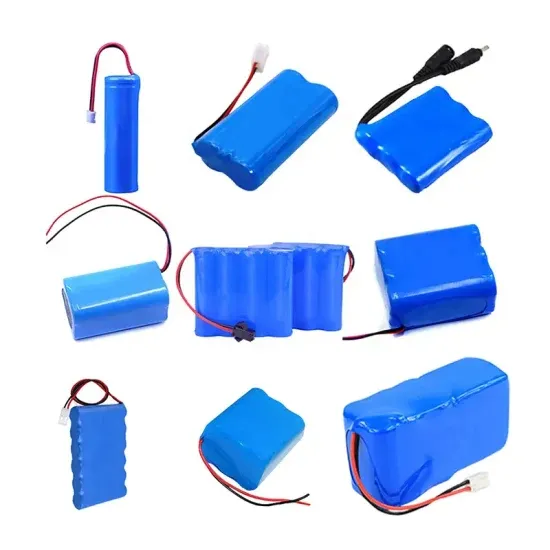

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

What are the naming rules for lithium ion batteries?

The naming rules for cylindrical lithium-ion battery cells follows a standardized format based on the cell’s dimensions, and usually represented by a five-digit code, where each digit provides specific information about the cell’s dimensions. Here’s a breakdown of the representation: What does 18650 means?

Industry Information

- Large-capacity energy storage batteries in East Africa

- Asmara energy storage equipment box manufacturer

- Rabat station-type energy storage system function

- Photovoltaic solar panels in rural Gomel Belarus

- Rwanda Energy Storage Container Factory 125kWh

- Price comparison of Thimphu grid-connected inverters

- UPS uninterruptible power supply laid flat

- 1500w solar inverter in China in Iraq

- Multifunctional communication base station wind and solar complementary production enterprise

- Czech solar photovoltaic tile supplier

- Price and lifespan of photovoltaic panels

- Tskhinvali outdoor power supply installation

- China 1 5 kva hybrid inverter in Sudan

- Battery energy storage system and maintenance of communication base stations

- How much does a monocrystalline photovoltaic panel cost in Sydney Australia

- Investment returns of wind power with energy storage

- Outdoor power cabinet manufacturer in Porto Portugal

- Solar power generation systems are available for sale in South Sudan

- How to make a container generator set

- Huawei outdoor power mobile equipment

- Inverter 24v to 220v price

- Bahrain photovoltaic panel manufacturer

- Berlin quality battery cabinet retail

Commercial & Industrial Solar Storage Market Growth

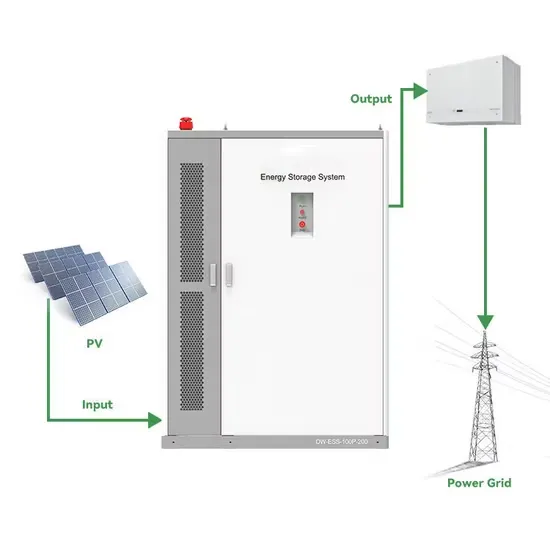

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.