Energy storage battery box refrigeration calculation

How is energy storage capacity calculated? The energy storage capacity,E,is calculated using the efficiencycalculated above to represent energy losses in the BESS itself. This is an

Cooling Capacity Estimation of Cold Storage Plant: A

May 21, 2024 · Factors like compressor capacity, evaporator design, condenser type, and refrigerant selection are carefully evaluated to optimize energy efficiency, reliability, and

Refrigeration Formulas and Calculations

Capacity is a measure of the amount of cooling provided by a refrigeration or air conditioning system. It is the product of the refrigerant circulated and the net

8. CALCULATION OF COLD STORE REFRIGERATION LOAD

Dec 17, 2023 · 8.1 Cold store capacity There is no method of defining cold store capacity that satisfies the requirements of everyone concerned with cold storage. Storage capacity based

Calculation of heat capacity of energy storage container

Download scientific diagram | Calculation of heat storage capacity and energy stored in PV-Ref, PV-PCM and PV-PCM-W for the experiment conducted for three consecutive days 30 January

HOW TO DESIGN A BESS (BATTERY ENERGY

Mar 11, 2023 · The design of a BESS (Battery Energy Storage System) container involves several steps to ensure that it meets the requirements for safety,

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integrates vapor compression

Refrigeration Formulas and Calculations

These formulas are commonly used in the field of refrigeration and air conditioning to calculate various performance parameters of a refrigeration

Proceedings of

Apr 19, 2023 · Energy storage technology has a positive significance in improving the absorption capacity of new energy, regulating the peak and valley of electricity consumption, and

Energy storage battery box refrigeration calculation

The energy storage capacity,E,is calculated using the efficiencycalculated above to represent energy losses in the BESS itself. This is an approximation since actual battery efficiency will

Chiller Capacity Calculation: Formula, Example,

Oct 10, 2024 · Chiller capacity is usually shown in the brochure or specification sheet. However, after the installation, the chiller may operate in different

Net Refrigeration Capacity Equations and

Accurate calculation of net refrigeration capacity is essential to ensure efficient and effective cooling. This article provides an overview of the equations and

Cold Room Calculation and Component Selection in

Jan 15, 2025 · Version 1.10 Calculation of cold room capacity, calculation and selection of all required system components in one go within Coolselector®2.

(PDF) REFRIGERATION SYSTEMS SELECTIONS, SIZING AND TROUBLESHOOTING

Apr 1, 2014 · A refrigeration system is a combination of components and equipment connected in a sequential order to produce the desired refrigeration effect (cooling or heating).

Calculating Cooling Load

Cooling Capacity Calculation The last thing we need to do is calculate the cooling capacity required to remove this heat gain load from the environment. For this,

Refrigeration System Design: Complete Guide

Jun 23, 2025 · Refrigeration system design explained with key formulas, easy calculations, and practical tips. Perfect for engineers, students, and HVAC

Cold Room Calculation and Component Selection in

Jan 15, 2025 · Calculation of cold room capacity, calculation and selection of all required system components in one go within Coolselector®2. To prolong lifetime and usability of perishable

How to Calculate Refrigeration Capacity in Tons: A

Aug 1, 2024 · Whether you are a homeowner wanting to determine the capacity for your household fridge or an industry professional looking to optimize a cold storage unit,

Design of Cold Chain Container Energy Storage and

Oct 24, 2021 · The development of Energy Internet promotes the transformation of cold chain logistics to renewable and distributed green transport with new distributed energy cold chain

Containerized Battery Energy Storage System

Jun 28, 2024 · Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems

Container Handbook

Sep 17, 2003 · This page can only be viewed using frame-enabled browsers Container Handbook Homepage: Refrigerated containers and CA technology Dr. Yves Wild Refrigerated containers

Energy Modeling Guideline for Cold Storage and

Dec 19, 2013 · The purpose of this guidance document is to assist designers of refrigerated storage facilities or any section of that building that achieves controlled storage conditions

Research and application of containerized

3 days ago · It discusses various aspects such as energy storage thermal management system equipment, control strategy, design calculation, and

Cold Room Refrigeration calculator

Jun 13, 2023 · On-line refrigeration calculation for sizing up installations and equipments for industrial and commercial refrigeration applications.

Design of Cold Chain Container Energy Storage and

Oct 24, 2021 · The development of Energy Internet promotes the transformation of cold chain logistics to renewable and distributed green transport with new distributed energy

DESIGNING AN HVAC SYSTEM FOR A BESS CONTAINER:

Jun 8, 2023 · The Battery Energy Storage System (BESS) is a versatile technology, crucial for managing power generation and consumption in a variety of applications. Within these

Industrial Refrigeration Best Practices Guide, 3rd ed.

Apr 3, 2018 · Background This Guide identifies and discusses best practices for making industrial refrigeration systems both energy-efficient and productive. The highest levels of efficiency in

How to Calculate Heat Load in Cold Storage

Apr 3, 2025 · Accurate heat load estimation is critical for the efficient design of cold storage refrigeration systems. Misjudging these loads can lead to

Integrating Cold Thermal Energy Storage for Air

Nov 26, 2024 · A common configuration for transcritical CO2 booster systems in supermarkets involves air conditioning (AC) supplied by cooling a water-glycol

Calculation of refrigeration capacity of energy storage

Accurate calculation of refrigeration capacity is vital for optimizing energy efficiency and maintaining the desired temperature in refrigeration systems. If the capacity is

Chapter 18: REFRIGERATION LOAD

18.1 MULTIPLE PURPOSES OF LOAD CALCULATIONS It is mandatory that refrigeration load calculations be performed during the design stage in order to

Refrigeration Capacity

Capacity of Refrigerator In order to express the cooling capacity of a refrigerating machine, i.e. the rate of heat removal from the refrigerated space, the common and standard unit used is a ton

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

(PDF) Refrigerated Transport: State of the Art,

Nov 2, 2021 · This paper provides a review of (a) currently used systems and alternative technologies that could reduce the environmental impacts of road

Energy consumption analysis and optimization of cold stores

May 1, 2024 · In the food industry, for example, the energy consumption of refrigeration systems, including production, circulation, and storage, accounts for 35% of the total energy

AE103-The Refrigeration Load

Aug 15, 2025 · This is the third of a series of publications comprising the Copeland Refrigeration Manual. Although each separate part covers a specific area of refrigeration theory and

What is Refrigeration Capacity and How Does it Affect Your

Jul 23, 2024 · The refrigeration capacity of a system depends on several factors, including the type of refrigerant used, the energy input, and the efficiency of the system. Higher refrigeration

Cooling Load Calculation for Cold Rooms

Feb 17, 2022 · Cooling Load Calculation for cold rooms. In this article we''ll be looking at how to calculate the cooling load for a cold room.

6 FAQs about [Calculation of refrigeration capacity of energy storage container]

How is net refrigeration capacity calculated?

The net refrigeration capacity is calculated by subtracting the heat gains and losses from the gross refrigeration capacity. This includes factors such as heat transfer through the walls, floor, and ceiling, as well as air leakage and moisture infiltration.

What is the formula for refrigeration capacity?

Capacity is a measure of the amount of cooling provided by a refrigeration or air conditioning system. It is the product of the refrigerant circulated and the net refrigeration effect. The formula for capacity is: Where c is the capacity in Btu/min, q is the refrigerant circulated in lb/min, and NRE is the net refrigeration effect in Btu/lb.

How do you calculate the cooling capacity of a refrigerator?

To calculate the cooling capacity of a refrigerator, you need to understand the concept of British Thermal Units (BTUs), which is a measure of energy required to change the temperature of a given amount of water by one degree. The cooling capacity of a refrigerator is typically measured in tons, where one ton is equivalent to 12,000 BTUs per hour.

How to increase net refrigeration capacity?

Another strategy is to optimize the system configuration, such as reconfiguring the piping layout or improving the insulation. Additionally, adjusting the operating conditions, such as the evaporator temperature or condenser temperature, can also impact the Net Refrigeration Capacity.

What is net refrigeration capacity?

The net refrigeration capacity is a crucial parameter in the design and operation of refrigeration systems. It represents the actual cooling capacity of a system, taking into account factors such as heat transfer, insulation, and air circulation.

What factors affect the net refrigeration capacity of a refrigeration system?

Several factors affect the net refrigeration capacity of a refrigeration system, including the temperature difference, air flow rate, and humidity levels. The temperature difference between the hot and cold sides of the system affects the heat transfer rate, while the air flow rate affects the convective heat transfer coefficient.

Industry Information

- How to accept energy storage cabinets

- Comoros Compressed Air Energy Storage Power Generation

- Panama containerized generator supply

- US New Energy Storage

- Features of Belmopan Energy Storage Battery

- KW cost of home energy storage equipment

- Maputo Wind Solar and Energy Storage Power Generation Company

- What are the batteries for integrated 5g communication base stations

- Inverters and energy storage in Santo Domingo

- Photovoltaic power station transformation into energy storage power station

- Sarajevo ap6 battery cabinet

- Price of 20 battery cabinet

- Customized cylindrical lithium battery in Alexandria Egypt

- Huawei Croatia Energy Storage Power Supply

- Several brands of Swedish outdoor communication battery cabinets

- Outdoor wireless network base station

- USA Folding Container Wholesale

- Is photovoltaic energy storage better in parallel or series

- Household solar light 30x40mm

- What is the energy storage cabin production equipment

- Introduction to the Remote Energy Storage Project

- Outdoor power supply production and wholesale

- Container Energy Storage Equipment Product Specifications

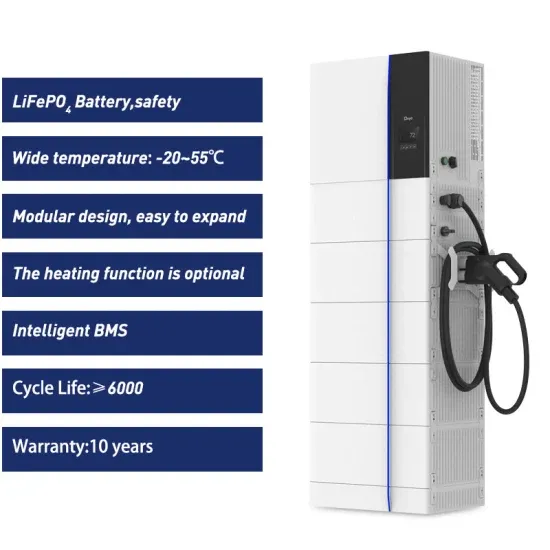

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

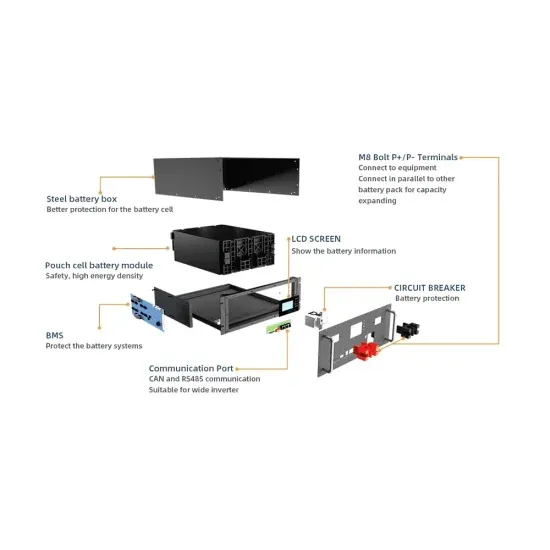

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.