design requirements for new energy storage battery cabinets

Design approaches for Li-ion battery packs: A review In a different paper, Arora et al. proposed a Robust Design Methodology to design battery packs for electric vehicles considering

Choosing the Right Battery Storage Cabinet: A

Jun 5, 2025 · Discover essential considerations when selecting a battery storage cabinet for lithium-ion batteries. Learn about ventilation, fire safety,

New UL Standard Published: UL 1487, Battery Containment

2 days ago · Learn about the first edition of UL 1487, the Standard for Battery Containment Enclosures, a binational standard for the United States and Canada published by UL

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Thermal management systems in battery energy storage cabinets are vital for regulating the internal temperature of the batteries. As batteries discharge and charge, they

Do Lithium Ion Batteries Require A Battery Room? Storage Requirements

Apr 16, 2025 · Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

Ventilation and Thermal Management of Stationary

Jan 10, 2023 · The purpose of the document is to build a bridge between the battery system designer and ventilation system designer. As such, it provides information on battery

Designing Industrial Battery Rooms: Fundamentals and

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards. 1. Space

Lithium Battery Charging Cabinet: The Essential Guide to

May 9, 2025 · The widespread use of lithium-ion batteries across various industries and applications—ranging from power tools to electric vehicles—has led to increasing concern

Requirements for battery enclosures – Design

May 24, 2019 · Requirements for battery housings in e-vehicles are extensive: regulatory requirements; functional requirements; consideration of the installation conditions,

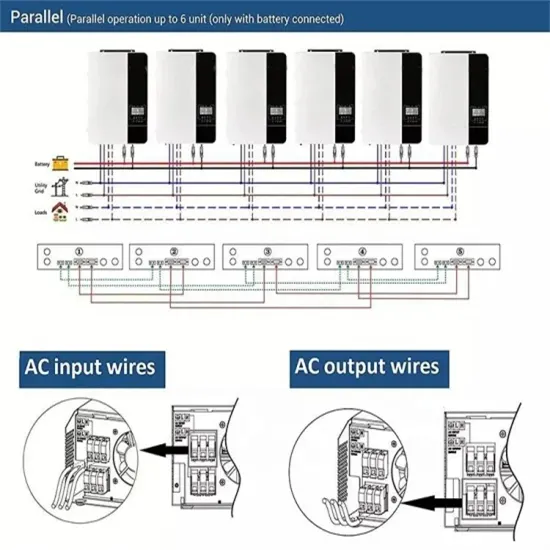

Battery Cabinets vs. Battery Racks

Aug 27, 2018 · Cabinet design, by contrast, must address the problem of removing heat as well as any off-gassing from the battery. Cabinet-mounted

Battery Cabinet Phase Requirements | HuiJue Group E-Site

The Silent Challenge in Energy Storage Deployment As global renewable integration accelerates, battery cabinet phase requirements emerge as a critical yet underdiscussed bottleneck. Did

Battery Enclosures Tech Sheets

Dec 4, 2023 · The battery enclosure contributes to the structural and safety aspects of the body in white while protecting high-voltage batteries from damage and water. These complex

Battery Cabinet Cost Structure and Optimiza-tion

Jan 12, 2024 · Chapter 2 describes how UPS devices and battery cabinets work and what their applications can be. Chapter 3 deals with the DFMA method which was used when analyzing

Case study-Outdoor Battery Cabinet

Aug 30, 2023 · Designed to be positioned outdoors, the electrical cabinet''s adherence to stringent waterproofing standards becomes a paramount

Energy Storage Battery Pack Enclosure size optimization and

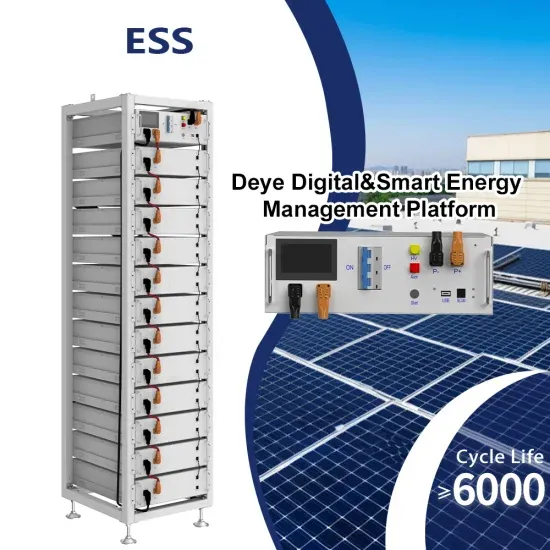

May 9, 2025 · Modular battery pack/cabinet design: build scalable modules and battery cabinets through standardized size battery cells (such as 280Ah, 314Ah batteries), supporting flexible

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

Designing a Battery Pack?

The wider system and it''s requirements are fundamental to the design of a battery pack. This means we need to understand the power electronics and how they

Choosing the Right Battery Storage Cabinet: A

Jun 5, 2025 · This comprehensive guide provides a detailed overview of safety, design, compliance, and operational considerations for selecting and using

Technical requirements for cabinet battery compartment

Safety requirements for batteries and battery rooms can be found within Article 320 of NFPA 70E. layout, wiring, and key industrial-use components. The technical storage or access is strictly

Requirements for battery enclosures – Design

May 24, 2019 · When designing e-mobiles - and thus the batteries or battery cases - there are some basic requirements that have to be taken into account, both from the technology as well

Charging and storage area | CEMO

A small cabinet size is therefore also completely in the spirit of what the fire brigade would prefer. That said, there is no need to forego flexible storage in

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

Stationary UPS Sizing Calculations – Part Six

2 days ago · in Article " Stationary UPS Sizing Calculations -Part Four ", we explained Selection and sizing of UPS protective devices (CBs or Fuses).

Battery Room Design Requirements

It does not cover maintenance free or computer room type batteries and battery cabinets. Main keywords for this article are Battery Room Design

Stationary UPS Sizing Calculations – Part Seven

5 days ago · electrical engineering including electrical design courses, electrical calculations, electrical worksheets, electrical programs and electrical books

General requirements for the installation of UPS

Oct 21, 2023 · Monitoring: Regularly check the battery system for issues and follow maintenance schedules. Safety Equipment: Have safety gear and

How to design an energy storage cabinet: integration and

Jan 3, 2025 · How to design an energy storage cabinet: integration and optimization of PCS, EMS, lithium batteries, BMS, STS, PCC, and MPPT With the transformation of the global

5 Steps to Design Your Outdoor Battery Cabinet

Apr 23, 2025 · Design your outdoor battery cabinet with these 5 steps: choose the right size, materials, cooling, safety features, and ensure easy maintenance.

New UL Standard Published: UL 1487, Battery Containment

2 days ago · Removable storage batteries shall not be stacked or charged in an enclosed cabinet unless the cabinet is specially designed and approved for such purpose 2027 International

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

Designing Industrial Battery Rooms: Fundamentals and

Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article

6 FAQs about [Battery cabinet design requirements]

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

What should a battery cabinet have?

Handles – provides an easy way to handle the battery cabinet. Battery holding brackets – they ensure the battery is always in a fixed position (no movement). Cooling plates – some have cooling plates that help to control the enclosure temperature. Insulation system – insulation is also a safety measure a battery cabinet should have.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

What rating should a battery cabinet have?

Indoor battery cabinet should have at least NEMA 1 rating. On the other hand, outdoor enclosures for batteries should have a NEMA 3R rating. It is important to note that the NEMA and IP rating varies depending on where you will install the enclosure. Indoor Battery Box Enclosure 2. Mounting Mechanism for Battery Cabinet

What are the requirements for a battery layout?

The layout should accommodate: 2. Structural Requirements Floor loading capacity is critical - industrial batteries typically weigh 1500-3000 kg/m². For VLA (flooded) batteries, acid-resistant floor coatings compliant with AS/NZS 2430.3.2 are required.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

Industry Information

- Kyrgyzstan Industrial and Commercial Energy Storage Cabinet Manufacturer

- BMS power battery equalization price

- Sao Paulo Brazil photovoltaic glass modules

- Rooftop photovoltaic dedicated inverter

- Slovenia solar energy storage power supply price

- Energy storage and solar

- How much current does a 450W photovoltaic panel draw

- Hot sale double throw breaker in China distributor

- Base station embedded power cabinet

- Huawei Energy Storage Container Advantages

- Eg801060v inverter

- Container outdoor power supply manufacturers

- Open photovoltaic glass manufacturer

- Power supply side energy storage increases power generation costs

- Container energy storage assembly production line

- Construction site photovoltaic folding container house wholesale

- Container energy storage system lithium battery pack cost

- Bangladesh energy storage container price

- Photovoltaic energy storage 40MWH

- 300wh power station in China in Brisbane

- Lithium battery efficient energy storage

- Ethiopian lithium battery bms manufacturer

- Which photovoltaic solar panel is better

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.