Toyota opens its first EV battery plant in the US,

Feb 6, 2025 · On Wednesday, Toyota announced that its $14 billion EV battery plant in North Carolina is open for business. The new facility will begin

Car battery cabinet production

A Storemasta lithium-ion battery cabinet can simultaneously charge multiple workplace batteries in a safe and protected environment. Storemasta offers an 8 and 18 outlet model of battery

Why Panasonic Opened one of the Largest EV

Aug 3, 2025 · Panasonic''s Kansas, US factory aims for a 32 GWh capacity to support rising electric vehicle market demands Panasonic has officially

Europe will open 250 battery factories by 2033.

Dec 28, 2023 · Due to the increasing demand for electric vehicles (EVs), it is expected that nearly 250 battery factories will be installed in the European

List of Largest EV Manufacturing Plants

May 25, 2023 · An electric vehicle manufacturing plant is an industrial facility dedicated to the production, distribution, and recycling of electric vehicles (EVs).

Designing EV Battery Manufacturing Plants: A

Apr 23, 2025 · In an EV battery plant, production involves several stages, including electrode preparation, cell assembly, battery module formation, and final testing. The design should

Canada is pouring billions of dollars into the

Sep 30, 2023 · Northvolt, a Swedish battery manufacturing giant, says it will build a new multibillion-dollar electric vehicle battery plant east of Montreal.

A Comprehensive Guide To EV Car Battery Manufacturing Plant

Jun 21, 2023 · Car battery assembly plants are crucial components in the production of high-performance batteries for electric vehicles. In this detailed blog post, we will provide an in

GM, Hyundai announce EV battery plants for the

Apr 26, 2023 · GM and Hyundai are the latest automakers to announce plans to build new electric vehicle battery plants in the US. GM is working with

The Battery Cell Factory of the Future | BCG

Jan 30, 2025 · Optimizing cell factories for next-generation technologies and strategically positioning them in an increasingly competitive market is key to

EV Battery Facilities

Ardmac specialises in building facilities for EV battery production, offering turnkey solutions for clients in the automotive industry.

EV Battery Factory in Kansas to be Powered by

Oct 4, 2023 · A new electric vehicle battery factory in Kansas needs so much energy that the state is delaying the retirement of a coal plant to make sure

This $500M EV battery material plant is the first

Feb 18, 2025 · Japan''s UBE has broken ground in Louisiana on a DMC and EMC plant – key components for lithium-ion batteries in EVs and battery storage.

One of Kentucky''s largest electric vehicle battery plants begins production

5 days ago · Commercial production of electric vehicle batteries is underway at the BlueOval SK plant in Kentucky''s Hardin County.

Top 10: EV Factories | EV Magazine

Apr 23, 2025 · This requires a global effort to manufacture EVs quickly and cost effectively. In this week''s top 10, we examine the innovation occurring at

A vast new UK battery plant just secured £1B to

May 13, 2025 · AESC is building a £1B EV battery plant in Sunderland, boosting UK production after a tariff-slashing deal with the US.

Here''s a list of recent electric vehicle and battery

Apr 25, 2024 · General Motors, Ingersoll, Ont. Canada''s first full-scale electric vehicle manufacturing plant officially opened in southern Ontario at the end of

PM Modi To Inaugurate Maruti Suzuki''s Electric Car, Battery

16 hours ago · PM Modi to inaugurate Maruti Suzuki''s new EV and battery plant in Gujarat, where the eVitara SUV will be built for India and 100 global markets.

Powering the Future: Inside the State-of-the-Art

Dec 17, 2023 · To produce these batteries in large volumes, specialized plants known as electric car battery plants are necessary. These facilities are

2024 to 2025 in automotive production EV batteries,

Dec 30, 2024 · Tesla leads electric vehicle and battery technology innovation with a growing, flexible production network and innovative battery production agility Tesla''s relentless drive to

VWAC starts production of its first high-voltage

Apr 21, 2023 · VWAC is the first battery system plant wholly invested by Volkswagen Automatic Transmission (Tianjin) Co., Ltd. With an initial annual

LG Energy Solution''s $5.5 Billion Stand-Alone

Apr 4, 2024 · The complex consists of two manufacturing facilities which are the company''s first stand-alone cylindrical and ESS battery plants in North

Tesla Opens Shanghai Megafactory for Battery

Feb 13, 2025 · Tesla has officially opened its Megafactory in Shanghai. The facility is expected to produce 10,000 Megapack units annually, with a total

£1bn secured for Sunderland electric car battery

May 9, 2025 · A £1bn investment has been secured for a new electric car battery plant, the government has said. It is hoped the new gigafactory being built at

BATTERY CELL PRODUCTION IN EUROPE: STATUS QUO

Jul 1, 2024 · With 14 million electric vehicles sold and 706 GWh of batery energy installed, the global electric vehicle industry and the associated batery market grew by 35% and 44%,

The EV Battery Manufacturing Process: Step by

Jun 5, 2024 · The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric

Global EV and Battery Manufacturing Capabilities

Sep 14, 2023 · The plant will focus on processing end-of-life hybrid and electric-vehicle batteries, gigafactory scrap and end-of-life consumer batteries to extract critical materials like nickel,

U.S. Battery Gigafactories [2025 List] | EV Supply Chain

9. 41 GWh: Ultium Cells Lansing - Michigan, USA 10. 41 GWh: Ultium Cells Warren - Ohio, USA Battery factories in the U.S. The reshoring and building of a domestic lithium battery supply

Some of the biggest EV battery factory projects

Jun 30, 2024 · General Motors General Motors has four electric vehicle battery plants in various stages of planning, construction and production with two joint

How to Setup an EV Manufacturing Plant in India?

However, setting up an EV manufacturing plant setup in India requires in-depth knowledge of the country''s regulations, infrastructure, and market demand.

13 New EV Battery Factories In US Within the

Jan 18, 2022 · In addition to the fewer than ten electric vehicle battery plants that are already in operation in the United States, according to the US Department

Electric Vehicle Battery Manufacturing Plant Report 2025

IMARC Group''s report, titled "Electric Vehicle Battery Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and

Toyota Battery Manufacturing North Carolina

When Toyota Battery Manufacturing North Carolina comes online in 2025, it will have 14 production lines including four supporting battery production for Hybrid Electric Vehicles and

Hyundai and LG Energy open Indonesia''s first

Jul 3, 2024 · Hyundai and LG Energy Solution have opened a $1.1bn battery cell plant in Indonesia as the south-east Asian country works to build an electric

Designing EV Battery Manufacturing Plants: A

Apr 23, 2025 · Discover the essential steps and considerations for designing efficient EV battery manufacturing plants. This guide covers site selection, layout optimization, and sustainable

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

6 FAQs about [Electric car battery cabinet production plant]

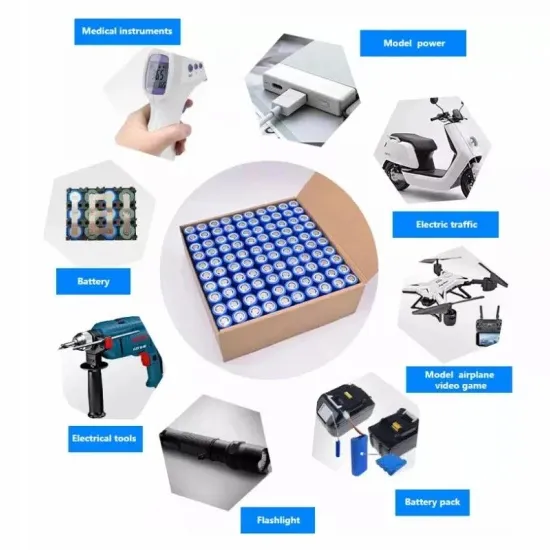

What is EV battery manufacturing process?

EV battery manufacturing processes are complex, sensitive, and delicate, in a multi-stage sequence with mixing, pumping, coating, injection, calendering, ageing and assembly operations. EV battery contaminants include moisture, particles and static, as well as chemical and electrical fire and safety risks.

Why is a reliable battery manufacturing process important?

The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric vehicle batteries are also in high demand, which puts pressure on manufacturers to maximize production without compromising quality.

Where does Tesla make EVs?

Tesla's gigafactory for EV production in Lin-gang, which is also the first plant of its kind that the US EV maker has built overseas, was the largest foreign-invested manufacturing project in Shanghai with a total investment of 50 billion yuan.

What is the production process of electric batteries?

The production process of electric batteries includes many steps. Before going over each step, let’s review the structure of battery cells. Table of Contents 1. Mixing of the Slurry Preparation 2. Coating & Calendering 3. Slitting of the Sheets 4. Identification for Traceability 5. Stacking 6. Foil-to-Tab Welding 7. Filling, Degassing & Sealing 8.

What are the EV battery contaminants?

EV battery contaminants include moisture, particles and static, as well as chemical and electrical fire and safety risks. Therefore, robotics and automation are extensively used along with mini environment, to provide both product component protection and personnel safety.

What is the most important component in an EV battery?

The most important component in an EV battery is the cell. Cells are where the energy of the battery is stored. While different chemistries exist, lithium-ion batteries are the most common on the market because they offer the best compromise between energy density and cost.

Industry Information

- 1300w motor 24v inverter

- Solar power satellite factory in Turkmenistan

- Mobile base station power cabinet circuit

- Wholesale solar power supply in Karachi

- Swiss portable energy storage power company

- Photovoltaic inverter F14

- Guinea communication base station wind and solar complementary building area

- Differences between room temperature superconductors and energy storage batteries

- Gabon UPS outdoor power service

- Huawei s new energy storage battery material

- Havana MW Energy Storage Container

- Three major pieces of energy storage equipment

- Number of times the energy storage power station is charged

- Circuit breaker in substation in Panama

- New Energy Battery Factory Container Base Station

- Reykjavik Solar Photovoltaic Power Plant System

- China tandem circuit breaker in Afghanistan

- Grenada City Battery Cabinet Wholesaler Address

- Cape Verde Commercial Off-Grid Energy Storage Power Station

- Prices of outdoor communication battery cabinets and base stations in Ecuador

- Austria Communication Base Station Photovoltaic Power Station

- Will 5G communication base stations use electric adjustment in the future

- Baku Industrial Energy Storage Cabinet Customization

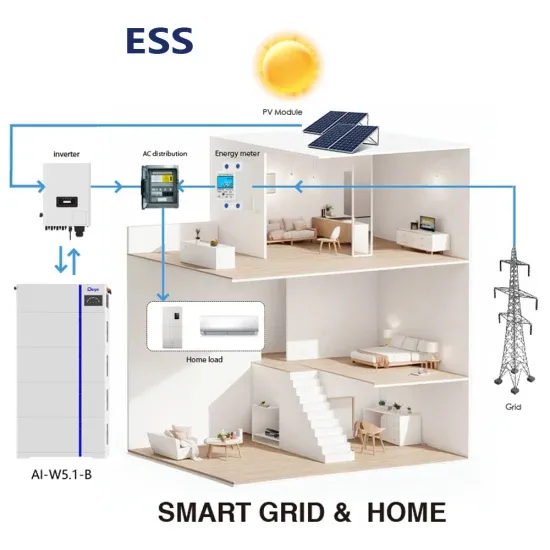

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.