Shaft-less flywheels-2022

Feb 22, 2022 · The shaft significantly impacts the flywheel design. This paper investigates several typical flywheel designs and their stress analysis. A simplified analysis method is given for

Design and fabrication of hybrid composite hubs for a multi

Jan 1, 2014 · A composite hub was successfully designed and fabricated for a flywheel rotor of 51kWh energy storage capacities. To be compatible with a rotor, desig

Flywheel Energy Storage System Basics – Power

Apr 14, 2023 · 3. Based on a permanent magnet motor design, flywheels can continuously cycle rapidly with minimal heat. In contrast, other motor

Vacuum flywheel energy storage

A flywheel energy storage system typically works by combining a high-strength, high-momentum rotor with a This assembly is contained inside a vacuum / containment vessel and operates

Microsoft Word

Mar 30, 2020 · The flywheel operates at a peak speed of 35,000 rpm, pulling power down to a minimum speed of 20,000 rpm. The tests conducted on the system have verified expected

Design optimization and fabrication of a hybrid composite flywheel rotor

Nov 1, 2012 · This paper discusses three different rim design cases of a hybrid composite flywheel rotor using strength ratio optimization. The rotor is composed of four hybrid composite rims.

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Rotor Design for High-Speed Flywheel Energy Storage

Jun 14, 2022 · More recently, flywheel systems were developed as true energy storage devices, which are also known as mechanical or electromechanical batteries. A remarkable example of

Stability Test Analysis and Design of High-load Magnetic

Sep 26, 2022 · As the core component of FESS(Flywheel Energy Storage System), the performance of magnetic levitation bearing directly affects the stability of high-speed rotor and

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · A typical flywheel energy storage system [11], which includes a flywheel/rotor, an electric machine, bearings, and power electronics. Download: Download high-res image (273KB)

Overview of the motor-generator rotor cooling system in a flywheel

Abstract: Motor-generators (MGs) for converting electric energy into kinetic energy are the key components of flywheel energy storage systems (FESSs). However, the compact diameters,

Design and Performance Analysis of Super

Aug 4, 2022 · The optimal design of a super highspeed flywheel rotor could improve flywheel battery energy density. The improvement of flywheel battery

A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies. A FESS consists of several key

Rotors for Mobile Flywheel Energy Storage | SpringerLink

May 4, 2023 · Flywheel rotors are a key component, determining not only the energy content of the entire flywheel energy storage system (FESS), but also system costs, housing design,

Shape optimization of energy storage flywheel rotor

Jun 17, 2016 · Then the downhill simplex method is adopted to solve the nonlinear optimization problem in multidimensional space. Finally, we obtain the optimized shapes of flywheel rotor

DOE ESHB Chapter 7 Flywheels

Mar 17, 2022 · Over the past 50 years of the development of flywheel energy storage systems, numerous unusual configurations have been explored. These include straight fibers oriented

Design of flywheel energy storage device with high

Jun 28, 2025 · The multistage flywheel energy storage device designed in this paper adopts a two-stage flywheel on the basis of the above flywheel energy storage device, forming a

Flywheel energy storage systems: A critical

Jul 19, 2021 · Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

Rotor Design for High-Speed Flywheel Energy Storage

Sep 25, 2018 · Contemporary flywheel energy storage systems, or FES systems, are frequently found in high-technology applications. Such systems rely on advanced high-strength materials

Development of a High Specific Energy Flywheel Module,

Aug 6, 2020 · Flywheel Applications For Space Flywheels For Energy Storage Flywheels can store energy kinetically in a high speed rotor and charge and discharge using an electrical

Design, Fabrication, and Testing of 10 MJ Composite

May 2, 2016 · To maximize the specific energy of the flywheels, the rotor mass is concentrated in the composite rim, at the largest possible spin radius. The flywheels utilize light-weight, flexible

Flywheels | Climate Technology Centre & Network | Tue,

Aug 12, 2025 · The mechanics of energy storage in a flywheel system are common to both steel- and composite-rotor flywheels. In both systems, the momentum (the product of mass times

Preparation of a Formatted Technical Work for the

Mar 30, 2020 · The flywheel, which operates in a vacuum, is supported by AMBs to minimize bearing losses, and has a high power motor/generator coupled to an efficient power

Thermal Performance Evaluation of a High-Speed

Mar 30, 2020 · Abstract-This paper presents the loss analysis and thermal per-formance evaluation of a permanent magnet synchronous motor (PMSM) based high-speed flywheel

Flywheel energy storage

Sep 10, 2013 · Flywheel energy storage works by accelerating a cylindrical assembly called a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational

Flywheel Energy Storage System Basics

Sep 23, 2021 · Today, flywheel energy storage systems are used for ride-through energy for a variety of demanding applications surpassing chemical batteries.

Strength Analysis of Carbon Fiber Composite Flywheel Energy Storage

Dec 18, 2024 · The dimensions of the flywheel energy storage device for power frequency regulation using carbon fiber composite materials, as described in reference [24], simplify the

Flywheel Energy Storage Systems | Electricity

1 day ago · RotorVault''s flywheel cells can be containerized for simple and scalable deployments. Each module is housed within a durable, weather

Carbon Fiber Flywheels

Carbon Fiber Flywheels Beacon''s flywheel is essentially a mechanical battery that stores kinetic energy in a rotating mass. Advanced power electronics and a motor/generator convert that

Energy Storage Flywheel Rotors—Mechanical Design

Energy is stored in a fast-rotating mass known as the flywheel rotor. The rotor is subject to high centripetal forces requiring careful design, analysis, and fabrication to ensure the safe

A Review of Flywheel Energy Storage System

Sep 7, 2023 · The operation of the electricity network has grown more complex due to the increased adoption of renewable energy resources, such as wind

Analysis and optimization of a novel energy storage

Aug 9, 2023 · The shaft significantly impacts the flywheel design. This paper investigates several typical flywheel designs and their stress analysis. A simplified analysis method is given for

Flywheel Energy Storage Systems | Electricity

1 day ago · RotorVault flywheel storage systems provide reliable energy storage solutions for residential, commercial and grid-scale applications worldwide.

Rotor Design for High-Speed Flywheel Energy Storage

Jun 14, 2022 · Contemporary flywheel energy storage systems, or FES systems, are frequently found in high-technology applications. Such systems rely on advanced high-strength materials

A review of flywheel energy storage rotor materials and

Oct 19, 2023 · Therefore, the selection of appropriate rotor materials and the design of rotor structure are the key to reducing the cost of flywheel energy storage, which is crucial for the

Mechanical Design Calculations of Flywheel Generator

Jan 17, 2020 · The flywheel rotor, filament wound carbon fi- bre/epoxy composite, will have storage capacity 10 MJ of energy @ 17000 rpm with Energy storage density of 77.5 J/g and

AAS 02-063 (DRAFT

Aug 6, 2020 · These combined functions are achieved by the simultaneous and balanced operation of two or more energy storage flywheels. An energy storage flywheel typically

6 FAQs about [Energy storage flywheel rotor assembly]

What is a flywheel energy storage system?

Contemporary flywheel energy storage systems, or FES systems, are frequently found in high-technology applications. Such systems rely on advanced high-strength materials as flywheels usually operate at speeds exceeding 10,000 rpm. Vacuum enclosures and magnetic bearing systems are frequently employed to minimize energy losses due to friction.

What is a flywheel rotor?

Flywheel rotors are a key component, determining not only the energy content of the entire flywheel energy storage system (FESS), but also system costs, housing design, bearing system, etc. Using simple analytic formulas, the basics of FESS rotor design and material selection are presented.

How energy is stored in a flywheel rotor?

Energy is stored in a fast-rotating mass known as the flywheel rotor. The rotor is subject to high centripetal forces requiring careful design, analysis, and fabrication to ensure the safe operation of the storage device. 1. Introduction

How to reduce the cost of Flywheel energy storage?

Therefore, the selection of appropriate rotor materials and the design of rotor structure are the key to reducing the cost of flywheel energy storage, which is crucial for the promotion of flywheel energy storage. Several review papers address different aspects of FESS research.

What is a 7 ring flywheel energy storage system?

In 1999 , the University of Texas at Austin developed a 7-ring interference assembled composite material flywheel energy storage system and provided a stress distribution calculation method for the flywheel energy storage system.

How to design a flywheel rotor?

When designing a flywheel rotor, on the premise of meeting the energy storage capacity requirements, the designed flywheel should be compact in volume, light in weight, and low in cost. Specific energy storage for different rotor shapes has been considered, using the shape factor Ks defined as . (8) E m = K s σ max ρ

Industry Information

- NAS does not have an uninterruptible power supply

- Outdoor power supply 12 volts

- Lead-acid battery management for Australian communication base stations

- Solar energy 5800 watts

- Standard value of protection voltage for communication base stations

- Bern Energy Storage Lithium Battery Cost Performance

- Do double-glass photovoltaic panels generate electricity on both sides

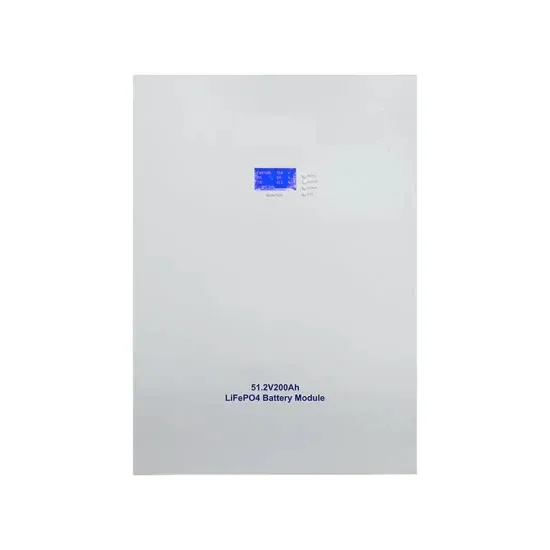

- Power station energy storage lithium battery

- Portable power supply for transportation

- On grid inverter 5kw in China in Slovakia

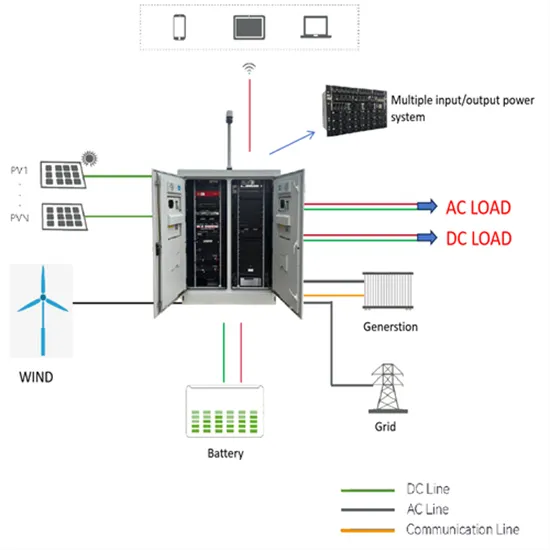

- Gabon Photovoltaic New Energy Storage Field

- St John s outdoor energy storage power supply price

- Can the high frequency inverter rotate

- Gambia distributed energy storage cabinet manufacturer

- Green Energy Storage System Supplier

- Home battery cabinet parameters

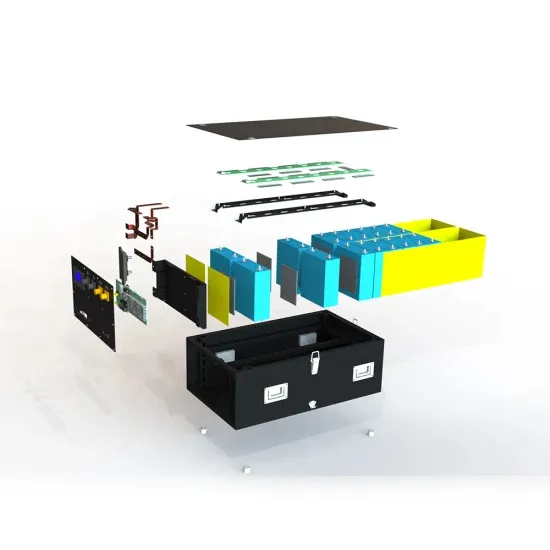

- Battery pack inside the battery cabinet

- 120 000W inverter

- Wind turbine wind power station

- China 300 watt solar inverter in Korea

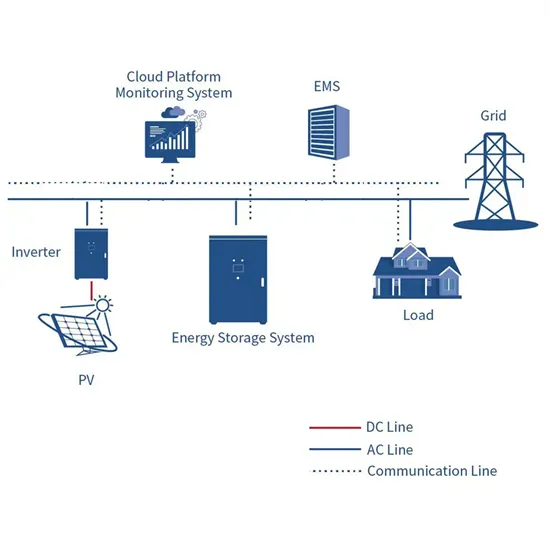

- User-side chemical energy storage battery access

- Belgian energy storage cabinet manufacturing company

- Which base station is best for 5g communication

Commercial & Industrial Solar Storage Market Growth

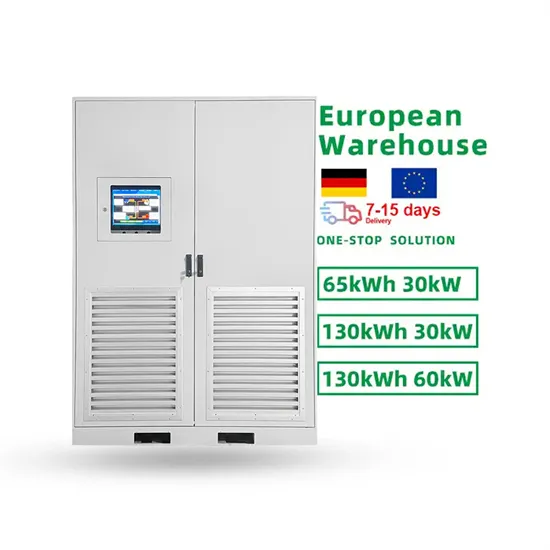

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.