ICL Breaks Ground on $400 Million Battery

Aug 9, 2023 · The 140,000-square-foot facility is expected to produce 30,000 metric tons of LFP and will serve as the foundation for the company''s global

Lithium Processing Systems and Equipment

Aug 11, 2025 · Electric vehicles and the lithium batteries that power them have become a critical component of a worldwide strategy towards sustainability.

Battery plant fire in southeast Missouri causes

Nov 1, 2024 · As a fire burned in the Critical Mineral Recovery lithium-ion battery recycling plant near Fredericktown on Wednesday, emergency services urged

Lithium batteries produced in Port Louis

The first rechargeable lithium battery was designed by Whittingham (Exxon) and consisted of a lithium-metal anode, a titanium disulphide (TiS 2) cathode (used to store Li-ions), and an

Port louis energy storage lithium battery

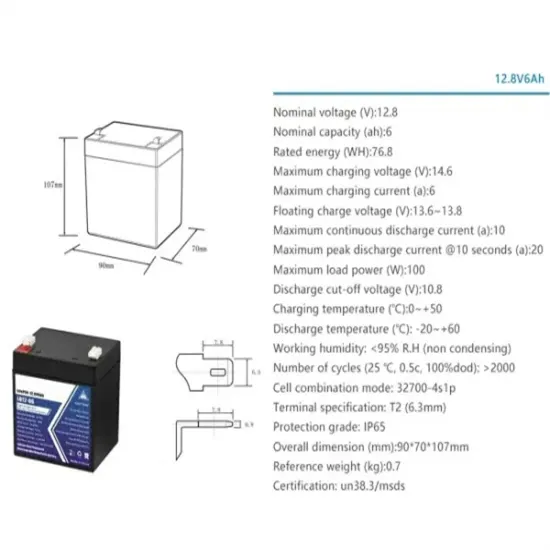

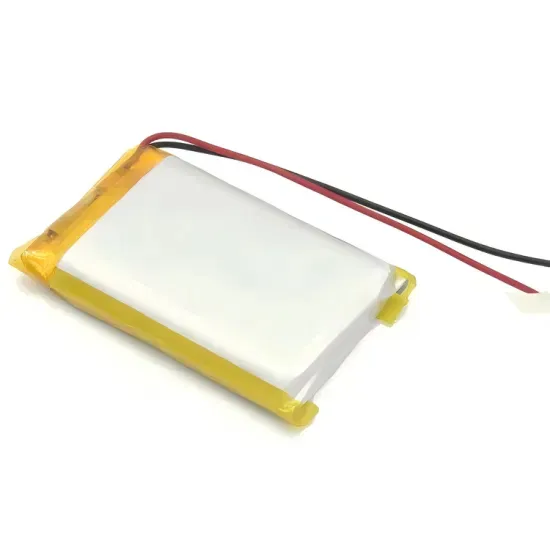

lymer lithium battery spot in Port Louis. This article will simplify the understanding of lithium polymer batteries by detailing their features, function, and wide-r

Port Muskogee gets the largest lithium refinery

Jan 11, 2024 · Battery-grade lithium is very prevalent in china, but not so big in the united states ’s a huge national security concern since the

Atlas Lithium''s Modular Processing Plant Arrives in Brazil,

Mar 10, 2025 · Boca Raton, Florida– (Newsfile Corp. – March 10, 2025) – Atlas Lithium Corporation (NASDAQ: ATLX), a leading lithium development company, announces the

Port Louis lithium battery energy storage technology factory

ICL breaks ground on $400M St. Louis battery materials plant The 140,000-square-foot plant will be one of the country''''s first large-scale battery materials manufacturing sites, according to the

Avalon dives into the details of proposed

Apr 21, 2024 · The refinery would convert lithium concentrate into a lithium hydroxide product that is coveted by battery manufacturers in the electric

Lithium processing pilot plant in WA''s Pilbara to

Aug 5, 2023 · A Pilbara miner is trying to harness renewable energy to reduce carbon emissions from the very lithium it produces for products such as

EPA expands air sampling around Missouri

Nov 1, 2024 · Federal officials are increasing air monitoring around a southeast Missouri lithium-ion battery plant that caught fire, the Environmental Protection

First large-scale battery separator facility breaks

Nov 19, 2024 · Asahi Kasei Battery Separator Corporation marked a step in its commitment to supporting the North American electric vehicle (EV) market by

port louis lithium battery energy storage project bidding

Battery Materials and Energy Storage ICL plans to build a 120,000-square-foot, $400 million LFP material manufacturing plant in St. Louis. The plant is expected to be operational by 2024 and

Tesla Lithium Refinery Groundbreaking

Jan 25, 2025 · Today, we are breaking ground on Tesla''s in-house lithium refinery, located in the greater Corpus Christi area of Texas. Once complete,

ICL Starts Construction on $400M Battery

Aug 10, 2023 · ICL, a specialty minerals producer, broke ground on its $400 million lithium iron phosphate (LFP) facility in St. Louis. The facility, predicted

ICL to build Li battery plant in the US – Argus Metals

Apr 10, 2025 · Israeli special minerals company ICL started construction of a lithium iron phosphate (LFP) battery plant in the US to supply energy storage and electric vehicle

Asahi Kasei to Construct a Lithium-ion Battery

April 25, 2024 Asahi Kasei Corp. Asahi Kasei announced today that it will construct an integrated plant in Ontario, Canada for the base film

What lithium batteries are produced in Port Louis

Global specialty minerals company ICL has celebrated the ground-breaking of its battery materials manufacturing plant in St Louis, Missouri, which is expected to be the first large-scale lithium

Cost Of Lithium-ion Battery Manufacturing Plant & Machinery

An Introduction Lithium-ion batteries have become the most critical applications of lithium and storage technology in the fields of portable and mobile applications (such as laptops, cell

Fire at Missouri battery plant causes evacuations

Oct 31, 2024 · The plant has the capacity to process more than 60,000 tons of electric vehicle and consumer-grade lithium-ion batteries. The story will be

Lithium Battery Port Louis

How much does ICL''s new battery plant cost? sential battery materials. ICL''s investment in the plant was augmented by a $197 million grant from the Will ICL build a phosphate plant in St

Port louis energy storage lithium battery

Port Louis lithium battery energy storage technology factory is in operation. ST. LOUIS - St. Louis will be at the forefront of a $2.8 billion expansion of domestic manufacturing of batteries for

Atlas Lithium Achieves Milestone with Processing Plant

Mar 10, 2025 · The successful arrival of Atlas Lithium''s modular processing plant in Brazil marks a significant advance in its efforts to become a leading lithium producer. With an innovative

New plant, tech make LA lithium production

Jun 28, 2024 · IBAT has developed a modular, transportable plant that can be set up on under two acres of stable soil, with no concrete foundations or dozens

From Raw Materials to Finished Product: The

Nov 10, 2024 · In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge

Port louis lithium battery energy storage

What are lithium-ion batteries used for? Not only are lithium-ion batteries widely used for consumer electronics and electric vehicles,but they also account for over 80% of the more

Port Louis lithium energy storage power supply spot

Battery Materials and Energy Storage ICL to Lead Efforts in U.S. to Develop Sustainable Supply Chain for Energy Storage Solutions, with $400 Million Investment in New Lithium Iron

Video shows massive explosion rip through

Nov 1, 2024 · FREDERICKTOWN, Mo. (KTVI) – A massive fire broke out at the Critical Mineral Recovery facility, a battery processing plant south of St. Louis,

Attorney addresses safety measures after Fredericktown plant

Oct 31, 2024 · The plant is considered to be one of the largest lithium-ion battery processing facilities worldwide.

DOE BIL Battery FOA-2678 Selectee Fact Sheets

Oct 19, 2022 · Such a plant would feed a 50,000 metric ton per year conversion plant to produce battery grade lithium hydroxide to support domestic manufacturing of the lithium-ion battery

Lithium Extraction and Refining | Saltworks

Separate lithium ions from contaminants or concentrate brines for lithium extraction, reduced evaporation time or improved recovery.

port louis lithium battery energy storage

A lithium-ion or Li-ion battery is a type of rechargeable battery that uses the reversible intercalation of Li + ions into electronically conducting solids to store energy.

Louisiana becoming a hotbed of critical materials production

Aug 18, 2025 · Louisiana is fast becoming a hub for processing critical minerals, rare earths and electrolyte salts used to produce lithium-ion batteries, with one plant operating successfully

Port Louis Electric Energy Storage Charging Pile Manufacturing Plant

Minerals specialist company ICL has inaugurated a large-scale battery materials manufacturing plant in St. Louis, Missouri. The $400-million plant will manufacture materials for lithium iron

5 FAQs about [Port Louis lithium battery processing plant]

How much does ICL's new battery plant cost?

The $400 million facility is planned to be operational by 2025 and will help meet growing demand from the energy storage, electric vehicle (EV) and clean-energy industries for U.S.-produced-and-sourced essential battery materials. ICL’s investment in the plant was augmented by a $197 million grant from the U.S. Department of Energy.

How much LFP will ICL produce?

The 140,000-square-foot facility is expected to produce 30,000 metric tons of LFP and will serve as the foundation for the company’s global battery materials business. The new plant will be located on ICL’s existing Carondelet campus in St. Louis, which is recognized by the Justice40 Initiative as a disadvantaged community.

Who makes LFP batteries?

Taiwan-based Aleees is a long-standing LFP battery material manufacturer and global IP licensor. LFP is one of the fastest-growing sectors of the battery industry, as this technology offers superior safety at a lower cost and with a longer life.

Why is ICL building a new energy storage facility?

The new facility represents a significant expansion of ICL’s energy-storage portfolio and demonstrates the company’s commitment to developing high-quality specialty products for agricultural, food, energy and industrial applications. About ICL

What is the global demand for iron phosphate-based cathode active materials?

By 2031, E Source forecasts global demand for iron phosphate-based cathode active materials will reach more than 3 million tons, for a market value of more than $40 billion, due to a shift toward the safer and lower-cost cathode materials used in more affordable EVs and in energy storage solutions.

Industry Information

- Yaounde Off-Grid Energy Storage Battery

- Which UPS is the best in Greece

- Niger Solar Energy Storage

- Jinshasa Tower Communication Base Station Wind Power

- Cheap factory price 5 5 kw inverter manufacturer

- Wholesale solar power supply in Botswana

- Rcb circuit breaker for sale in France

- Taipei energy storage product prices

- Kigali Heavy Industry Energy Storage Cabinet Supplier

- Colombian energy storage fire equipment manufacturer

- Solar power system for cabin in Switzerland

- What is the inverter 12v240hz

- Cambodia photovoltaic carport with energy storage wholesale

- Wholesale 63a circuit breaker in indonesia

- Professional inspection of new energy battery cabinets

- High quality factory price main switchgear for sale

- Pretoria solar photovoltaic customization

- A container can hold solar panels

- How much does a large energy storage cabinet cost in Luxembourg

- Cylindrical lithium battery all

- Huawei Senegal foldable photovoltaic panels

- Distribution of the energy storage industry chain in the Democratic Republic of the Congo

- Cameroon Energy Storage Power Source Factory

Commercial & Industrial Solar Storage Market Growth

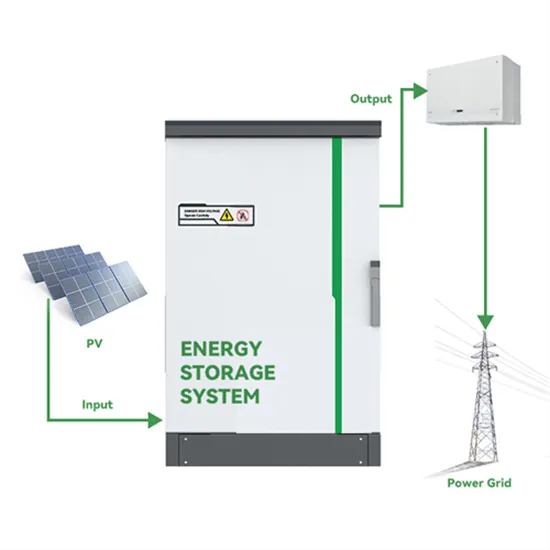

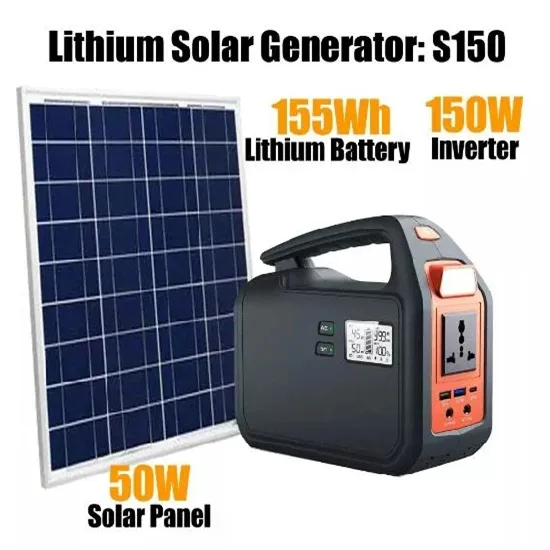

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.