Lithium iron phosphate comes to America

Jan 21, 2025 · Lithium iron phosphate comes to America Companies are planning the first large-scale factories in North America for the inexpensive battery raw

Production of Lithium Iron Phosphate (LFP) using sol-gel

Sep 26, 2022 · lithium iron phosphate for high rate Li-ion batteries: A review", Engineering Science and Technology, an International Journal, regenerated from spent batteries. Explore

Tesla Patents Low-Cost LFP Battery

Jan 17, 2025 · Lithium iron phosphate or LFP is at the heart of new technologies for electric vehicle manufacturers. Now, Tesla has developed a potentially

LiFePO4 Battery

Aug 1, 2025 · Lithium Ferrous Phosphate custom battery packs provide some of the safest Li-Ion battery technology in the world.Although the energy density is

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Lithium Iron Phosphate (LiFePO4, LFP), as an outstanding energy storage material, plays a crucial role in human society. Its excellent safety, low cos

Exploring sustainable lithium iron phosphate cathodes for Li

This review provides a comprehensive overview of the mining, beneficiation, processing, and purification processes of phosphorus, iron, and lithium ores. It explains the journey from

How Is the Manufacturing Process of Lithium Iron Phosphate Batteries

Feb 21, 2025 · The manufacturing process of lithium iron phosphate (LiFePO4) batteries involves several critical steps that ensure high performance and safety. These batteries are known for

Explore LFP Battery Raw Material: LFP Cathode

Jan 30, 2024 · Composed of lithium iron phosphate, the LFP cathode is what allows the battery to charge and discharge safely while offering long life

What Are LiFePO4 Batteries, and When Should

Sep 7, 2022 · How Are LiFePO4 Batteries Different? Strictly speaking, LiFePO4 batteries are also lithium-ion batteries. There are several different variations in

Mainstream production process of lithium iron

4 days ago · Lithium iron phosphate is the mainstream lithium battery cathode material, abbreviated as LFP, and its chemical formula is LiFePO4. LiFePO4

Buhler to Supply Process Technology for LFP Battery

Apr 11, 2025 · Swiss plant manufacturer Buhler Group has received a major order from FIB S.p.A., a subsidiary of Seri Industrial S.p.A., to equip its lithium iron phosphate (LFP) battery

Lithium iron phosphate battery pack process

Abstract: Lithium iron phosphate batteries (LiFePO 4) are becoming one of the main power resources for electric vehicles (EVs), and the non-uniformity of cells in a battery pack has

Lithium iron phosphate battery pack process

Comprehensive Guide to Lithium Iron Phosphate (LiFePO4) Battery Understanding LiFePO4 Battery Cell Grading . Lithium Iron Phosphate Battery (LiFePO4) cell grading is the process of

PRODUCTION PROCESS OF A LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Revolutionising Lithium Iron Phosphate Battery

Jun 19, 2025 · Discover how one-pot synthesis and metal-to-cathode processes revolutionize lithium iron phosphate battery production with superior efficiency.

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

LFP Battery Manufacturing Process: Components

May 16, 2024 · Overview of LFP Battery Components and Materials Lithium iron phosphate (LFP) batteries, a kind of lithium-ion battery, have obtained

How Do Lithium Iron Phosphate Battery Packs Work and

Lithium iron phosphate (LiFePO4) battery packs are a type of rechargeable battery known for their safety, longevity, and environmental friendliness. They operate by transferring lithium ions

Battery Pack Design | Dragonfly Energy

Our dedication to safety led us to employ lithium iron phosphate (LiFePO4) in our battery pack design. Also known as LFP, this chemistry is renowned for its

LFP Battery Manufacturing Process: Components

May 16, 2024 · Understanding the components and materials used in LFP batteries is crucial for comprehending the intricacies of the manufacturing

Battery Manufacturing Process: Materials,

Jul 3, 2024 · What Are the Types of Lithium Batteries? Part 2. Battery electrode production 2.1 Cathode Manufacturing The cathode is a critical battery

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · 1. Introduction In the dynamic landscape of energy storage technologies, lithium - iron - phosphate (LiFePO₄) battery packs have emerged as a game - changing solution.

8 LFP Battery Companies to Watch

Dec 20, 2022 · Lithium iron phosphate (LFP) batteries are a type of lithium-ion battery that has gained popularity in recent years due to their high energy

LiFePO4 VS. Li-ion VS. Li-Po Battery Complete

Mar 18, 2024 · Overview of Lithium Iron Phosphate, Lithium Ion and Lithium Polymer Batteries Among the many battery options on the market today, three

Status and prospects of lithium iron phosphate

Sep 23, 2024 · Lithium iron phosphate (LiFePO4, LFP) has long been a key player in the lithium battery industry for its exceptional stability, safety, and cost-effectiveness as a cathode

Lithium iron phosphate battery pack processing

Life cycle environmental impact assessment for battery-powered LFP: LFP x-C, lithium iron phosphate oxide battery with graphite for anode, its battery pack energy density was 88 Wh kg

lithium-iron-phosphate batteries lfp sarajevo

Lithium iron phosphate batteries (most commonly known as LFP batteries) are a type of rechargeable lithium-ion battery made with a graphite anode and lithium-iron-phosphate as the

Lithium Iron Phosphate Battery Packs | Electronic

A battery pack is a set of any number of battery cells connected and bound together to form a single unit with a specific configuration and dimensions. They may be configured in series,

LiFePO4 Cells Pack Assembly Line

Sep 13, 2024 · ALiFePO4 cells pack assembly line automates the process of assembling individual LiFePO4 cells into battery packs, ensuring consistency, precision, and efficiency.

Sarajevo single lithium iron phosphate battery

Europe''''s first LFP battery factory to be built in Serbia ElevenEs has developed its own lithium iron phosphate (LFP) technology for batteries for electric cars, buses, trucks, forklifts, other

Take the road of sustainable development, Maoxin advocate Sarajevo

[Lithium iron phosphate battery recycling and processing equipment manufacturer of Create brilliance with cohesion] Henan Maoxin Machinery Equipment Co., Ltd called on Recycling

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

The Role of Lithium Iron Phosphate (LiFePO4) in

Apr 18, 2025 · Discover how lithium iron phosphate (LiFePO4) enhances battery performance with long life, safety, cost efficiency, and eco-friendliness.

Production technology and process of lifepo4

Dec 28, 2023 · The main production process of lithium iron phosphate batteries can be divided into three stages: the electrode preparation stage, cell molding

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University has been researching lithium-ion battery production for many years. The

LFP Battery Pack Combined Heat Dissipation Strategy

Apr 28, 2024 · During the high-power charging and discharging process, the heat generated by the energy storage battery increases significantly, causing the battery temperature to rise

Manufacturing process of lithium iron

Through this series of steps, the assembly segment process provides a reliable guarantee for the production of high-performance lithium-ion batteries. The

6 FAQs about [Sarajevo lithium iron phosphate battery pack processing]

What is the production process of lithium iron phosphate (LFP) batteries?

The production procedure of Lithium Iron Phosphate (LFP) batteries involves a number of precise actions, each essential to guaranteeing the battery’s efficiency, security, and long life. The procedure can be broadly divided into material prep work, electrode fabrication, cell setting up, electrolyte filling, and development biking.

Why is quality control important for lithium iron phosphate (LFP) batteries?

Quality control and testing are essential components in the manufacturing procedure of Lithium Iron Phosphate (LFP) batteries. Provided the high demand for reliability and performance, it is imperative to ensure that every stage of production meets rigorous quality standards.

Is lithium iron phosphate a good cathode material for lithium-ion batteries?

Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing cost, good cycle performance, and environmental friendliness, it has become a hot topic in the current research of cathode materials for power batteries.

How to manufacture LFP battery?

The initial step in the LFP battery manufacturing procedure is the prep work of the raw materials. This includes manufacturing the lithium iron phosphate (LiFePO4) cathode product and procuring high-purity graphite for the anode.

Which olivine cathode material is best for lithium-ion batteries?

Compared with other lithium battery cathode materials, the olivine structure of lithium iron phosphate has the advantages of safety, environmental protection, cheap, long cycle life, and good high-temperature performance. Therefore, it is one of the most potential cathode materials for lithium-ion batteries.

What is the cathode product in LFP batteries cell?

The cathode product in LFP batteries Cell is lithium iron phosphate (LiFePO 4). This material is picked for its excellent thermal stability, safety and security account, and longevity. LFP uses a reduced power thickness contrasted to other lithium-ion chemistries yet gives a longer cycle life and greater resistance to abuse.

Industry Information

- 5g base station communication construction

- 12 volt inverter charging

- Cameroon inverter energy storage power supply outdoor

- How the solar energy and energy storage cabinet system works

- Baku photovoltaic glass manufacturer

- How many companies are involved in Lithuania s energy storage projects

- 5kw solar system with battery in Senegal

- Solar photovoltaic base station installation

- Where is the 5G base station in Libreville

- Lebanon Energy Storage Cabinet Wholesale Price Inquiry

- 2 million tons of photovoltaic glass

- Install energy storage photovoltaic at home

- Radio monitoring station investigates interference with integrated 5G base stations

- Libreville Rainproof Photovoltaic Panel Manufacturer

- The energy storage system is complementary to wind and solar

- Sarajevo emergency energy storage power supply production

- Battery Energy Storage Basic Topology

- Cooling system for energy storage batteries

- Ranking of Athens container energy storage companies

- Hot sale wholesale 1500 watt inverters Price

- Photovoltaic glass sun room manufacturer in Cordoba Argentina

- Where to buy solar photovoltaic panels in Nairobi

- Energy storage solution in Tampere Finland

Commercial & Industrial Solar Storage Market Growth

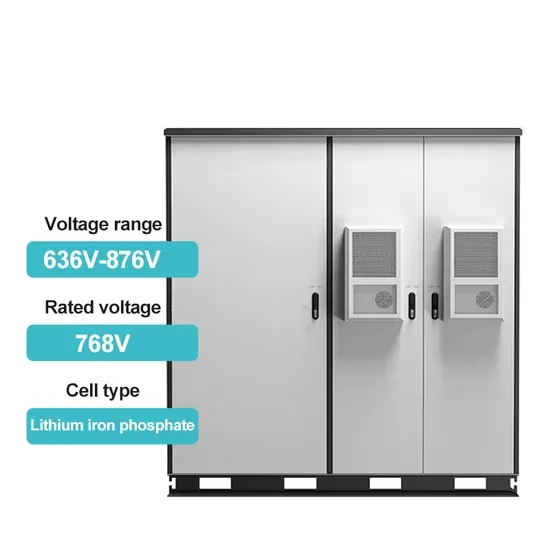

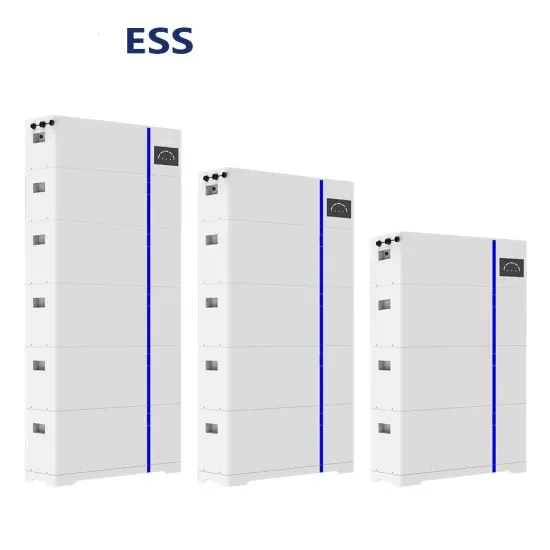

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.