Comparative analysis of cylindrical lithium-ion battery

Aug 1, 2025 · Understanding lithium-ion battery failure under mechanical abuse is critical for safety. While continuous compression is studied, the effects of intermittent loading and its

Cylindrical Lithium Ion Battery Global Market Insights 2025,

Mar 26, 2025 · Market Size and Growth Forecast The global cylindrical lithium-ion battery market is estimated to be valued between USD 15 billion and USD 17 billion in 2025, with a CAGR of

Comparison on Thermal Runaway and Critical

Mar 3, 2025 · In this work, the present research is reviewed in detail and future perspectives are proposed. This review on the critical characteristics of

Cylindrical Lithium Battery Cap: Manufacturing

May 21, 2024 · Cylindrical lithium batteries are popular for their efficiency, lifespan, and compact size. But their safety hinges on a crucial component:

Cylindrical Lithium Battery Cap: Safety

Conclusion: Manufacturing cylindrical lithium battery caps is a meticulous process. From material selection and welding to assembly, environment

Everything about Cylindrical Batteries, the Power

May 29, 2024 · The importance of cylindrical batteries is only growing because they are used widely from small electronic devices to EVs. In line with the

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion Battery Safety Lithium-ion batteries are one type of rechargeable battery technology (other examples include sodium ion and solid state) that supplies power to

Tab Design and Failures in Cylindrical Li-ion Batteries

Feb 15, 2019 · The tabs that connect the electrodes (current collectors) to the external circuits are one aspect of the cylindrical battery design that plays a role in reliability and safety. This paper

Study on the safety of cylindrical lithium-ion batteries under

This study aims to elucidate the safety performance of lithium-ion batteries under nail penetration conditions. Utilizing a custom-built experimental platform, we examined the effects of four

Cylindrical lithium battery classification and

May 17, 2023 · The structure of a typical cylindrical battery includes:casing,cap,positive electrode,negative

Lithium-ion Batteries are Safer Than Ever. That''s not Enough.

Jun 26, 2024 · Despite these challenges, safety advancements have greatly improved, with the failure rates of the most common cylindrical lithium-ion cells decreasing from 1 in 200,000 to 1

Lithium-ion Manufacturing and Risk Reduction

Mar 28, 2022 · The lithium-ion cell and battery manufacturing process requires stringent quality control. Improper design and manufacturing practices can

Safety modelling and testing of lithium-ion batteries in

Apr 12, 2018 · Battery safety is a key focus in the design of electrified vehicles. Here, the authors survey literature approaches for modelling and testing battery safety under abuse conditions,

Comparative Analysis of Cylindrical Lithium-ion Battery

Download Citation | On May 1, 2025, Nan Zhou and others published Comparative Analysis of Cylindrical Lithium-ion Battery Responses to Continuous and Intermittent Compression:

Questions and Answers Relating to Lithium-Ion

Jan 20, 2021 · Fire accidents involving electric vehicles can raise questions regarding the safety of lithium-ion batteries. This article aims to answer some

Cylindrical Lithium Technologies

5 days ago · Cylindrical Lithium battery technology by Panasonic Energy Co., Ltd. High Energy Formula and PTC Safety System.

A critical review of lithium-ion battery safety testing and

Aug 1, 2023 · The safety of lithium-ion batteries (LiBs) is a major challenge in the development of large-scale applications of batteries in electric vehicles and energy storage systems. With the

A Guide to Lithium-Ion Battery Safety

Jun 11, 2019 · Safety characteristics vary by Li-ion electrochemistry Overcharged (delithiated) positive can become unstable Passivation layer (SEI) can break down above 100°C

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

A review of lithium-ion battery safety concerns: The issues,

Aug 1, 2021 · Lithium-ion batteries (LIBs) with excellent performance are widely used in portable electronics and electric vehicles (EVs), but frequent fires and explosions limit their further and

The battery is like a living entity, we produce

EVE Energy Co., Ltd.The battery is like a living entity, we produce them with uncompromised respect and dignity.

What Keeps Lithium-Ion Batteries Safe?

Original branded cells and batteries with authentic safety marks have undergone extensive testing and are certified by approved accredited labs.

Safety performance and failure prediction model of cylindrical lithium

Mar 1, 2020 · In this paper, the safety performance model of cylindrical lithium-ion batteries, which is based on a second-order oscillation feature that is subjected to mechanical abuse is

Safety Analysis of Lithium-Ion Cylindrical

Feb 23, 2024 · Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes.

Experimental measurement and modeling of the internal

Dec 1, 2024 · The internal pressure evolution of cylindrical lithium-ion battery cells under abuse tests is evaluated in this work. The pressure evolution is recorded through a cavity at the

Calculation of the state of safety (SOS) for lithium ion batteries

Aug 30, 2016 · As lithium ion batteries are adopted in electric vehicles and stationary storage applications, the higher number of cells and greater energy densities increases the risks of

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In engineering applications such as electric vehicles and energy storage systems, the structural safety of cylindrical lithium-ion batteries is crucia

Design, Properties, and Manufacturing of

Jun 3, 2023 · This study conducts a design and process failure mode and effect analysis (DFMEA and PFMEA) for the design and manufacturing of cylindrical

Safety performance and failure prediction model of cylindrical

In this paper, the safety performance model of cylindrical lithium-ion batteries, which is based on a second-order oscillation feature that is subjected to mechanical abuse is proposed via a

Safety challenges and safety measures of Li

Sep 2, 2021 · To provide background and insight for the improvement of battery safety, the general working mechanism of LIBs is described in this review, followed by a discussion of the

Safety Analysis of Lithium-Ion Cylindrical

Jan 17, 2024 · Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes.

Lithium Ion Battery Safety Guidance

Oct 16, 2019 · The intent of this guideline is to provide users of lithium-ion (Li-ion) and lithium polymer (LiPo) cells and battery packs with enough information to safety handle them under

6 FAQs about [Luanda cylindrical lithium battery safety]

Are cylindrical lithium-ion batteries safe?

Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes. This study conducts a design and process failure mode and effect analysis (DFMEA and PFMEA) for the design and manufacturing of cylindrical lithium-ion batteries, with a focus on battery safety. 1.

Which cylindrical lithium-ion batteries have the worst consequences?

Among all types of cylindrical lithium-ion batteries, the 21700 exhibits the worst consequence, which is attributed to the adoption of high energy density LiNi 0.8 Co 0.15 Al 0.05 O 2 (NCA) and LiNi x Mn y Co z O 2 (NMC) cathode materials.

Are lithium ion batteries safe?

Major safety concerns for lithium-ion batteries are thermal runaway and explosion. Thermal runaway is a phenomenon where exothermic reactions occur within the cell, leading to a rapid temperature increase, potentially causing the cell to catch fire .

What are the OSHA standards for lithium-ion batteries?

While there is not a specific OSHA standard for lithium-ion batteries, many of the OSHA general industry standards may apply, as well as the General Duty Clause (Section 5(a)(1) of the Occupational Safety and Health Act of 1970). These include, but are not limited to the following standards:

Are lithium ion batteries flammable?

Some of these electrolytes are flammable liquids and requirements within OSHA’s Process Safety Management standard may apply to quantities exceeding 10,000 lb. Many of the chemicals used in lithium-ion battery manufacturing have been introduced relatively recently.

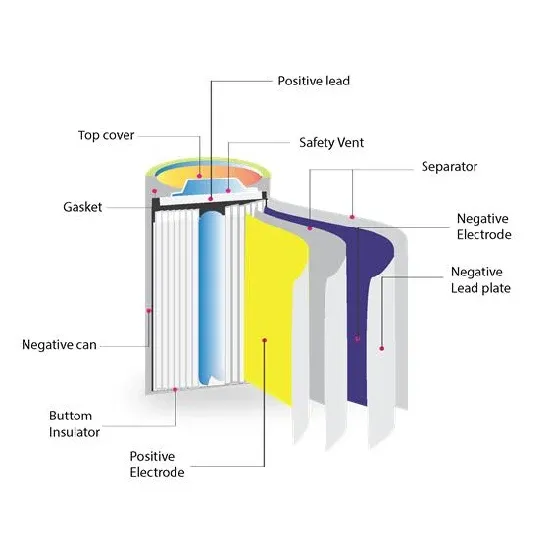

What is a cylindrical lithium ion battery?

Cylindrical batteries are composed of a rolled-up assembly called a jelly roll, which includes anode, cathode, and separator sheets tightly wound together and connected with electrical tabs. A schematic of a cylindrical lithium-ion battery is shown in Figure 2. Figure 2. Cylindrical battery structure.

Industry Information

- Photovoltaic performance of domestic energy storage battery cabinets

- One kilowatt 24 volt inverter price

- Hungary s new energy storage system

- High quality 300wh power station in China Wholesaler

- Canada PV 10kw off-grid inverter

- China circuit breaker outside in Angola

- Monterrey Energy Storage Project in Mexico

- Earth leakage breaker factory in Cairo

- What is the difference between battery swap stations and energy storage

- Solar 25W Battery

- China arc flash switchgear for sale supplier

- Energy storage battery for RV in Toronto Canada

- Communication base station flywheel energy storage UPS protocol

- 2200 sine wave inverter

- Energy storage system factory in Finland

- Comoros household energy storage box fire protection design

- Indian RV Solar System Solution

- Battery cabinet communication power supply auxiliary material price

- Are outdoor solar lights safe

- Huawei Tower Uninterruptible Power Supply Installation

- Funafoti container BESS wholesale

- Kingston multifunctional energy storage power supply customization

- High quality China samite circuit breaker supplier

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

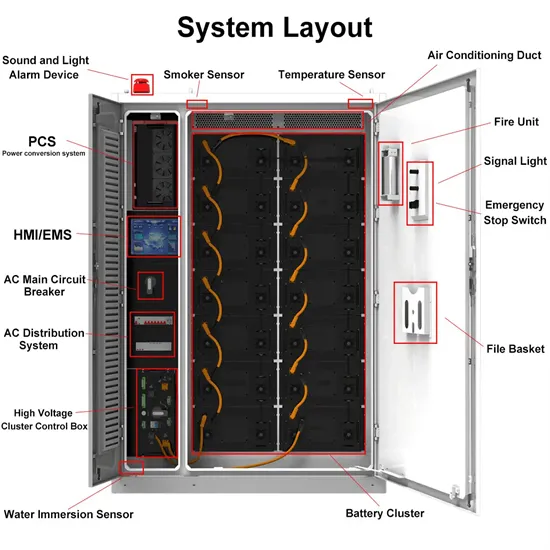

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.