Sample SOP/SOG – Responses to Incidents

Sample SOP/SOG – Responses to Incidents Involving Lithium-Ion Batteries and/or Energy Storage Systems This document provides arrival and on-scene

Lithium Batteries: Safety, Handling, and Storage

Nov 14, 2022 · Primary or Non-Rechargeable Lithium Cells Primary lithium batteries feature very high energy density, a long shelf life, high cost, and are non-rechargeable. They are generally

SAFE OPERATING PROCEDURE Lithium Battery Storage

Sep 17, 2024 · ROCEDURE Lithium Battery Storage and Disposal 1. Introduction The University is required to comply with legal obligations to minimise the risk of fire, damage, and in. y as a

Collaborative evaluation of SoC, SoP and SoH of lithium-ion battery

Sep 15, 2023 · Collaborative evaluation of SoC, SoP and SoH of lithium-ion battery in an electric bus through improved remora optimization algorithm and dual adaptive Kalman filtering algorithm

SOP

Jan 7, 2025 · SAFE OPERATING PROCEDURE Lithium Battery Storage and Disposal 1. Introduction The University is required to comply with legal

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Each phase plays a critical role in ensuring the performance, safety, and reliability of the battery module. With proper attention to quality and

Lithium Ion Battery

Feb 28, 2024 · The intent of this guideline is to provide users of lithium (LFP) cells and battery packs with enough information to storage handle them under normal and emergency

Comprehensive co-estimation of lithium-ion battery state of

Dec 10, 2022 · The single state estimation method estimates a battery state such as SOC, SOH, SOE, and SOP. In the co-estimation method, two or more battery states may be estimated.

LITHIUM-ION BATTERY GUIDELINES

Jul 31, 2024 · These guidelines provide requirements for lithium-ion (Li-ion) and lithium polymer (LiPo) cells and battery packs. These guidelines are established to ensure faculty, staff, and

SOP Manual for Primary Battery Manufacturing SOP-425

5 days ago · The "SOP Manual for Primary Battery Manufacturing" takes top priority in the battery manufacturing industry, providing a structured guide for standardized operating procedures

Battery State of Power Estimation

Dec 21, 2018 · The state of power (SOP) estimation of battery systems is indispensable to ensure the safe and reliable operation of electric vehicles (EVs). This chapter discusses

SOP xxx.0 Response to Incidents Involving Lithium Ion

Feb 21, 2024 · II. Definitions Lithium-ion Battery (herein referred to as LiESS): A rechargeable energy storage device/system that utilizes "lithium-ion" technology and a protection circuit

State of Charge, Health and Power in batteries. Definition

Feb 23, 2021 · State of Power (SoP) A battery''s state-of-power (SOP) is defined as the ratio of peak power to nominal power. The peak powe r, based on present battery -pack conditions, is

Joint estimation of SOC/SOP for lithium-ion batteries across

Abstract: Accurate state estimation is crucial for ensuring the safe and reliable operation of lithium-ion batteries. However, achieving simultaneous online estimation of multiple

LITHIUM BATTERY SAFETY

Jul 10, 2025 · Lithium battery fires and accidents are on the rise and present risks that can be mitigated if the technology is well understood. This paper provides information to help prevent

A novel active lithium-ion cell balancing method based on

May 6, 2025 · The simulation results show that the usable capacity using the proposed SoP-based method is improved by 16% as compared to the usable capacity of the battery pack

Active cell equalization for lithium-ion battery packs in

Jul 1, 2025 · This paper proposes an active cell equalization algorithm based on State-of-Power (SoP), which outperforms voltage and State-of-Charge (SoC) based equalization by reducing

TL-LFP Series Lithium-Ion Battery Operation

Feb 8, 2025 · The TL-LFP Series Lithium-ion Battery Operation Manual provides essential safety guidelines, operational instructions, and maintenance

Key Points of Lithium Battery PACK

Jun 27, 2024 · The lithium-ion battery pack manufacturing process involves selecting and matching battery cells, assembling the pack with a protective

Battery Safety SOP | SafetyDocs PDF & Word

This Battery Safety Safe Operating Procedure (SOP) provides a way for your business to outline step-by-step safe processes in regards to using batteries

Lithium Batteries: Safety, Handling, and Storage

Nov 14, 2022 · Electronics technicians (ETs) will follow safety procedures when assembling battery packs and handling batteries. The waste technician will review documents and follow

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

How to Revive a Lithium-Ion Battery: Step-by

Nov 21, 2024 · Improper storage of lithium ion battery like long-term storage in full charge or exposing it to extreme temperatures killed its lifespan. Knowing and

Recent advancements in battery state of power

Dec 1, 2024 · As a crucial indicator of lithium-ion battery performance, state of power (SOP) characterizes the peak power capability that can be delivered or absor

TP4056 datasheet

Nov 18, 2018 · The TP4056 is a complete constant-current/constant-voltage linear charger for single cell lithium-ion batteries. Its SOP package and low external component count make the

SOP xxx.0 Response to Incidents Involving Lithium Ion

Feb 21, 2024 · Most LiESS powered devices as well as Modules and Packs have a battery management system that monitors their internal state and keeps them operating within a "safe

State of power estimation of lithium-ion battery based on

Sep 1, 2021 · Abstract State of power (SOP) is an important parameter to characterize the power performance of lithium-ion battery. Different from State of Charge (SOC), SOP estimation

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Research on Multi-Time Scale SOP Estimation of

Mar 23, 2023 · Battery state of power (SOP) estimation is an important parameter index for electric vehicles to improve battery utilization efficiency and

Understand the Importance of Battery SOP in

Nov 6, 2023 · In this article, we''ll talk about what is SOP, why it matters, and how it impacts lithium battery management. We will explore the methods used to

9370

Jan 24, 2022 · 2. Enclosure (1) supersedes and replaces NPS Standard Operating Procedures (SOP) Safety & Usage Procedure for Lithium Polymer Batteries VI .4b, captures all formats of

State of power estimation of lithium-ion battery based on

Sep 1, 2021 · State of power (SOP) is an important parameter to characterize the power performance of lithium-ion battery. Different from State of Charge (SOC), SOP estimation

Power Estimation for Electric Vehicles''s Lithium

Jan 5, 2022 · State of power (SOP), as one of the key states of lithium-ion batteries, is defined as the peak power capability that a battery could deliver

6 FAQs about [Pack lithium battery sop]

What is a lithium ion / lithium polymer (LiPo) SOP?

se equipment or machines with batteries know the basic rules. The intent of this SOP is to provide users of lithium-ion (Li-ion) and lithium polymer (LiPo) cells and battery packs with enough informatio

What is the state of Power (SOP) in a lithium battery management system?

One of the important parameters in a lithium battery management system is the “State of Power” or battery SOP. While it might not be as widely recognized as its siblings, State of Charge (SOC) and State of Health (SOH), SOP plays an equally crucial role in determining a battery’s operational status and health.

What is the Li-ion battery storage guideline?

The intent of this guideline is to provide users of lithium (LFP) cells and battery packs with enough information to storage handle them under normal and emergency conditions. Caution must be taken in Li-ion battery storage, use, management, and disposal due to the potential for fire and injury if these batteries are misused or damaged.

What are the legal obligations relating to lithium-ion battery storage & disposal?

E OPERATING ROCEDURELithium Battery Storage and Disposal1. IntroductionThe University is required to comply with legal obligations to minimise the risk of fire, damage, and in y as a result of storage and disposal of lithium batteries. Every employer must ensure that all employees who handle lithium-ion batteries for their work or

How important is SOP estimation for high-power batteries?

For high-power batteries, such as those used in electric vehicles, SoP estimation is even more crucial. With a much higher power density than standard batteries, factors like SoC, temperature, discharge rate, and charging rate can significantly impact their performance and lifespan.

What factors affect a Li-ion battery pack's state of Power (SOP)?

Factors such as temperature, discharge rate, charging rate, state of charge (SoC), state of health (SoH), driving conditions, and power consumption are instrumental in accurately estimating both SoP and DTE. Accurately estimating the Li-ion battery pack’s State of Power (SoP) is crucial for understanding its capability to deliver power.

Industry Information

- Solar photovoltaic panel factory in Gaborone

- China all in one solar power system for sale

- Selling outdoor power supplies across borders

- Ljubljana Photovoltaic Glass Sun Room

- Wholesale new circuit breaker in Costa-Rica

- New Energy Seasonal Energy Storage

- Energy storage container assembly process and accessories

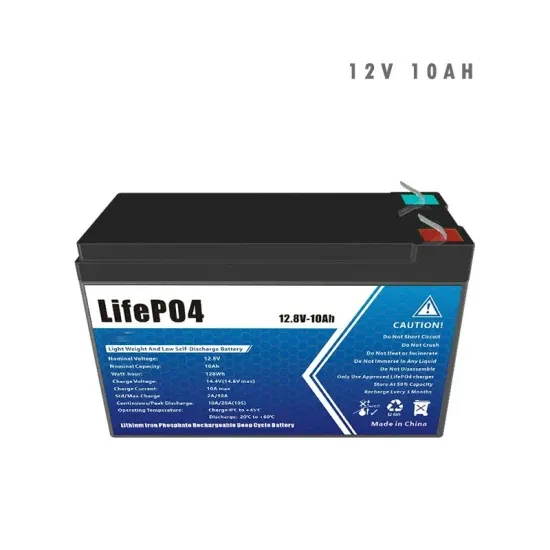

- Solar 12v lithium battery pack

- Pv breaker isolator for sale in Pretoria

- Cameroon inverter manufacturer

- China upgrade circuit breaker in Bandung

- Solar panels 420 watts

- Current Status of Power Consumption of Communication Base Stations

- Amman Shelter Battery Energy Storage Power Station

- Khartoum Liquid Cooling Energy Storage Enterprise

- Tashkent Photovoltaic Glass Project

- Factory price serket breaker in Tajikistan

- Thimbu communication base station inverter photovoltaic power generation brand

- Introduction to photovoltaic panel size specifications

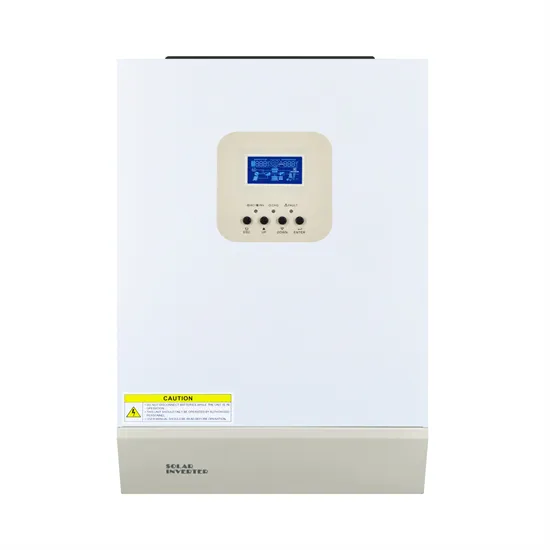

- Grid-connected inverter dsp

- Rcb circuit breaker in China in Bahamas

- Inverter 60v48v

- Malawi p-type double glass module

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.