(PDF) Review on Silicon Carbide based High-Fundamental

Jan 1, 2025 · This article provides a comprehensive review of Silicon Carbide (SiC) based inverters designed for High-Speed (HS) drive applications, which require higher output

Infineon supplies silicon carbide (SiC) power modules to Xiaomi

May 6, 2024 · Infineon provides two HybridPACK Drive G2 CoolSiC 1200 V modules for the Xiaomi SU7 Max. In addition, Infineon supplies Xiaomi EV with a broad range of products per

[MIUI Class Vol 22] Silicon Carbon Battery

May 6, 2025 · Silicon Carbon is used in batteries whereas Silicon Carbide is primarily used in power supplies like chargers, inverters, and other accessories. Silicon Carbide is more in-line

Infineon provides a broad range of products for Xiaomi''s

May 6, 2024 · The cooperation between the two companies will not only help stabilize the supply of silicon carbide for Xiaomi EV, but also help us build a high-performance, safe and reliable

Infineon supplies silicon carbide (SiC) power modules to Xiaomi

May 6, 2024 · Infineon Technologies AG (FSE: IFX / OTCQX: IFNNY), a global semiconductor leader in power systems and IoT, will provide silicon carbide (SiC) power modules

Is the silicon carbide promoted by Xiaomi Motors

Jun 16, 2024 · The silicon carbide power device suppliers selected by Xiaomi Auto are mainly from industry giants United Electronics and Infineon. With the successful "boarding" of silicon

Review on Silicon Carbide-Based High-Fundamental Frequency Inverters

Jun 18, 2025 · This article provides a comprehensive review of Silicon Carbide (SiC) based inverters designed for High-Speed (HS) drive applications, which require higher output

Viper Inverter Power Switch

Our solution for this challenge? The 800-Volt Silicon Carbide Inverter for Electrified Vehicles. Viper is the first 800-Volt inverter to use an innovative,

Infineon supplying silicon carbide power

May 7, 2024 · Picture: Infineon is providing a broad range of products, including silicon carbide power modules, for Xiaomi''s new SU7 smart EV (copyright:

onsemi''s EliteSiC technology powering 800V drive platform in Xiaomi

Aug 4, 2025 · Intelligent power and sensing technology firm onsemi of Scottsdale, AZ, USA says that its EliteSiC M3e silicon carbide (SiC) technology is powering an 800V drive platform

Infineon supplies silicon carbide (SiC) power

May 7, 2024 · Infineon Technologies has been selected to supply silicon carbide (SiC) power modules, specifically the HybridPACK™ Drive G2 CoolSiC™ and

After BYD, another Chinese company to mass

Jun 28, 2021 · After the mass production of this technology, it will be firstly equipped by Nio''s first sedan product, ET7, to provide a longer range for the

Xiaomi''s first car has SiC chips from Bosch on board

Aug 19, 2025 · The semiconductor material silicon carbide, which is a crucial part of the e-axle, is especially valuable for improving electric vehicles. SiC chips use up to 50 percent less energy,

Xiaomi and Infineon Extend Smart EV Partnership

May 6, 2024 · Xiaomi has solidified its partnership with Infineon Technologies, a key supplier in its transition from smartphones to electric vehicles. The collaboration involves Infineon providing

IPG5 800V Silicon Carbide Inverter

IPG5 is an 800V Silicon Carbide (SiC) inverter that supports ultra-fast charging and delivers exceptional powertrain efficiency. McLaren Applied have been pushing the boundaries of

Silicon Carbide Power Inverter Technology is

Sep 13, 2021 · This first-generation CoolSiC automotive MOSFET technology is optimized for use in EV traction inverters, with a focus on minimizing

Infineon Provides a Broad Range of Products for Xiaomi''s

May 6, 2024 · Infineon Technologies AG, a global semiconductor leader in power systems and IoT, will provide silicon carbide (SiC) power modules HybridPACK™ Drive G2 CoolSiC™ and

Xiaomi extends Infineon smart EV deal

May 6, 2024 · Xiaomi is extending its deal with Infineon Technologies as a key supplier in its move from smartphones to electric cars Infineon will provide

Silicon carbide based photovoltaic inverter price

Silicon carbide producers are migrating from 150 mm to 200 mm wafers. Production costs remain a challenge for SiC,but there is plenty of potential for reductions. The next generation of PV

SiC-Based Traction Inverters: Revolutionizing

Mar 18, 2024 · In terms of electric mobility, traction inverters based on silicon carbide (SiC) power devices are a huge step forward.

Fraunhofer ISE presents silicon carbide string

Oct 24, 2023 · Fraunhofer ISE researchers claim the new silicon carbide inverter is technically able to handle voltage levels of up to 1,500 V at 250 kVA in utility

800V Silicon Carbide Inverters for EV Market

Apr 14, 2025 · The integration of 800V silicon carbide (SiC) inverters into electric vehicle (EV) architectures introduces **unique aftermarket service challenges**, driven by technical

Infineon Offers Products for Xiaomi''s New SU7

May 6, 2024 · For Xiaomi EV''s recently unveiled SU7, Infineon Technologies AG has stated that it will supply silicon carbide (SiC) power modules HybridPACK

Infineon supplying silicon carbide power

May 7, 2024 · Infineon Technologies AG of Munich, Germany is to provide HybridPACK Drive G2 CoolSiC silicon carbide (SiC) power modules and bare

SMA America releases 99.2% efficient grid-scale

Mar 21, 2025 · The inverters use a silicon carbide metal-oxide-semiconductor field-effect transistor for high power conversion capability.

Infineon will supply Xiaomi with SiC modules

Infineon Technologies AG has announced it will supply Xiaomi EV with silicon carbide (SiC) power modules HybridPACK™ Drive G2 CoolSiC™ and bare

Infineon Partners with Xiaomi EV to Supply

May 6, 2024 · (IN BRIEF) Infineon Technologies AG, a semiconductor leader, will provide silicon carbide (SiC) power modules and bare die products to Xiaomi

Silicon Carbide Inverters Market

Jul 24, 2024 · How are customer preferences shifting between silicon carbide inverters and traditional silicon-based alternatives? Customer preferences are increasingly favoring silicon

Decoding the Silicon Carbide Electric Drive between Tesla and Xiaomi

Jan 16, 2025 · In 2018, Musk, who was trying his best to control Tesla''s production costs, suddenly raised the "silicon carbide banner" and installed 24 silicon carbide (SiC) MOSFET

Xiaomi Taps Infineon for SiC Power Modules

May 14, 2024 · Infineon Technologies AG will provide silicon carbide (SiC) power modules HybridPACK Drive G2 CoolSiC and bare die products to Xiaomi EV

Silicon Carbide Inverter

Aug 16, 2025 · ZF''s compact, robust, and in-house developed and produced silicon carbide (SiC) inverter for commercial vehicles delivers highly efficient

ST releases new generation of SiC power technology tailored

September 26, 2024 / SemiMedia / — STMicroelectronics is introducing its fourth generation STPOWER silicon carbide (SiC) MOSFET technology. The Generation 4 technology brings

Infineon Technologies to Deliver SiC Power

May 6, 2024 · Infineon Technologies AG will provide silicon carbide (SiC) power modules HybridPACK™ Drive G2 CoolSiC™ and bare die products to Xiaomi

6 FAQs about [Xiaomi silicon carbide inverter price]

Does Xiaomi eV have a silicon carbide power module?

Infineon Technologies AG (FSE: IFX / OTCQX: IFNNY), a global semiconductor leader in power systems and IoT, will provide silicon carbide (SiC) power modules HybridPACK™ Drive G2 CoolSiC™ and bare die products to Xiaomi EV for its recently announced SU7 until 2027.

Will Infineon provide SiC power modules to Xiaomi EV?

Infineon will provide SiC power modules HybridPACK Drive G2 CoolSiC and bare die products to Xiaomi EV for its recently announced SU7 until 2027. Infineon Technologies AG will provide silicon carbide (SiC) power modules HybridPACK Drive G2 CoolSiC and bare die products to Xiaomi EV for its recently announced SU7 until 2027.

Does Xiaomi eV have a coolsic power module?

Infineon Technologies AG has announced it will supply Xiaomi EV with silicon carbide (SiC) power modules HybridPACK™ Drive G2 CoolSiC™ and bare die products for Xiaomi’s recently launched SU7. Infineon’s CoolSiC-based power modules are designed to withstand higher operating temperatures, which enhances performance, driving dynamics, and lifespan.

Can traction inverters extend the range of electric vehicles?

Traction inverters based on this technology can potentially extend the range of electric vehicles. Since 2017, Infineon’s HybridPACK Drive, a power module family for electric vehicles, has sold nearly 8.5 million units. For the Xiaomi SU7 Max, Infineon will provide two HybridPACK Drive G2 CoolSiC 1200 V modules.

Does Infineon supply Xiaomi EV?

In addition, Infineon supplies Xiaomi EV with a broad range of products per car, including, for example, EiceDRIVER TM gate drivers and more than ten microcontrollers in various applications. The two companies also agreed to further cooperate on SiC automotive applications to fully utilize the benefits of Infineon’s SiC portfolio.

Does the new su7 have a silicon carbide eAxle?

The SU7 proves what industry experts have predicted for years: advanced electronics play an increasingly important role in defining the driving experience. And we are happy to say that the new SU7 is powered by a Bosch eAxle equipped with our own silicon carbide (SiC) chips.

Industry Information

- Cheap omega solar inverter for sale Factory

- Advantages of energy storage power stations

- Photovoltaic glass companies in Prague

- Bmser company energy storage battery

- Small energy storage cabinet outside the flywheel energy storage cabinet of the communication base station

- Building an uninterruptible power supply

- Microinverter and energy storage battery integrated

- How much does an outdoor power supply cost in Sao Paulo Brazil

- Dual-band outdoor wireless base station

- Commercial energy storage cabinet quotation

- Pyongyang Energy Storage Lithium Battery Project

- EU Power Frequency Off-Grid Inverter Sales

- New solar photovoltaic panels in the Middle East

- Best smart solar inverter for sale Price

- Power station energy storage policy requirements

- Manila Flexible Photovoltaic Panels

- Paraguay ge uninterruptible power supply

- Nepal 30kw high quality inverter for sale

- Sanaa Solar Photovoltaic Panels

- Pristina dedicated solar photovoltaic panels

- South Asia centralized energy storage equipment manufacturer

- Lithium battery pack residual value

- Mobile outdoor base station main construction

Commercial & Industrial Solar Storage Market Growth

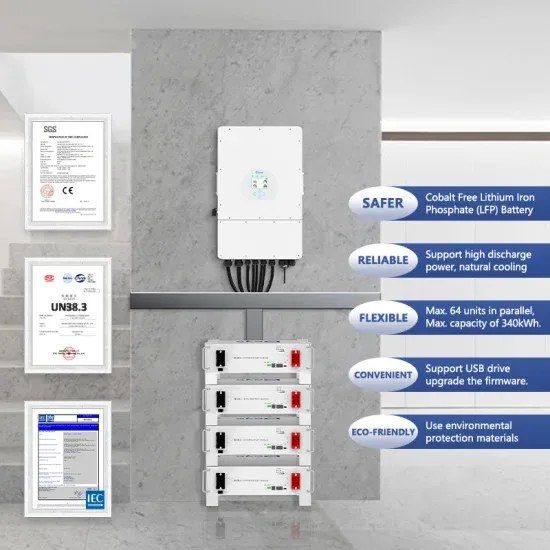

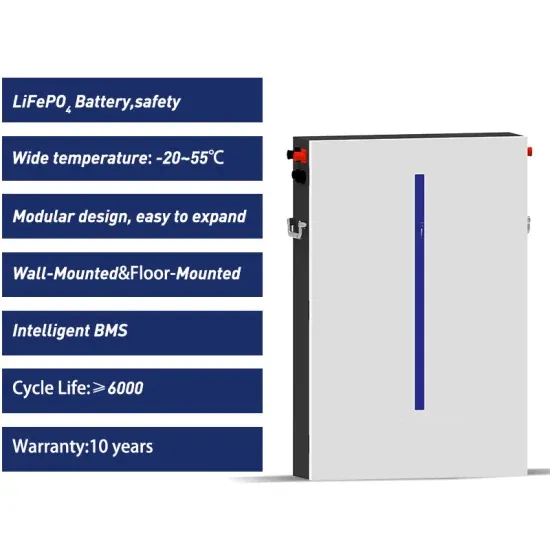

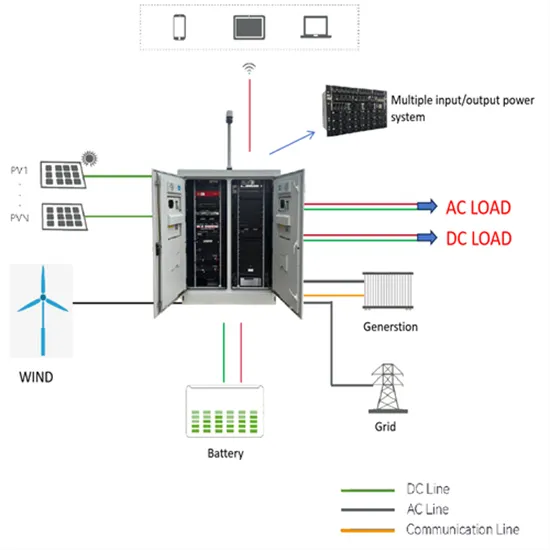

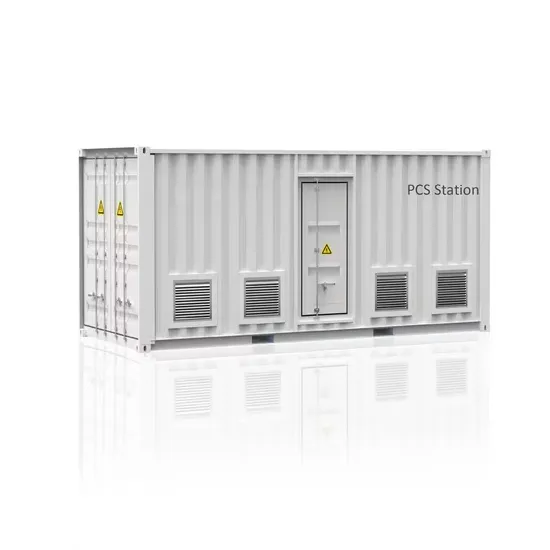

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.