ENSURING WORKER SAFETY IN ELECTRIC VEHICLE AND

Oct 2, 2023 · This rapid growth projection is bolstered by ambitious target-setting for the phase-out of internal combustion engine-powered vehicles in many developed regions, along with

India as an Emerging Manufacturing Hub for EV

Discover the growth of the EV battery market in India as the country seeks to achieve net zero emissions by 2070 and become a global player in EV

Lithium-ion Battery Manufacturing in India

The lithium-ion battery manufacturing in India is experiencing significant growth, presenting opportunities for localization within country''s battery supply chain.

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Key Points of Lithium Battery PACK

Jun 27, 2024 · Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling,

Everything You Need to Know About EV Battery

Jan 31, 2022 · EV batteries and battery packs are complex systems, requiring a comprehensive design and testing strategy to help ensure safe and efficient

Tesla''s Battery Production: How It Powers the

Apr 25, 2025 · Lower production costs: The battery pack becomes cheaper to build, and fewer components are required for assembly. Tesla''s control over

GM Li-Ion Battery Pack Manufacturing

Mar 14, 2014 · Relevance: GM''s Li-Ion Battery Pack Manufacturing project creates and retains jobs, establishes a US-based battery pack manufacturing capability, improves our energy

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Chinese battery makers set US lithium plan in

Apr 15, 2025 · Strategic shift, local focus The first facility, focused on battery pack assembly, is slated for near-term development. Meanwhile, the second is

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · From precise cell welding to smart BMS integration—uncover how lithium-ion battery packs are engineered for safety and power.

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · The lithium battery module PACK production line is a complex system project involving multiple links and aspects of management and

Battery Factory Planning

Together with product and process development, factory planning is an essential component on the way to competitive battery cell production. Several target

India''s lithium-ion cell supply chain – Leading

Apr 18, 2023 · India''s LiB Industry – Key players'' activity Ola Electric, Reliance and Rajesh Exports have been selected under the PLI scheme for receiving

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · Discover the key stages in the lithium-ion battery assembly process, from raw materials to pack assembly. Learn how battery-making

Requirements for a Process to Remanufacture

Jun 4, 2023 · An automotive battery pack for use in electric vehicles consists of a large number of individual battery cells that are structurally held and

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Current manufacturing processes for LIBs LIB industry has established the manufacturing method for consumer electronic batteries initially and most of the mature

Battery Production Planning

Optimize your battery production process with PEM Motion. Our expertise in cell, module, and pack production helps reduce time and cost, ensuring a

How To Establish A Battery Pack Manufacturing Factory

Feb 8, 2025 · Whether you''re targeting electric vehicles (EVs), energy storage systems (ESS), or consumer electronics, this guide outlines critical steps, budget considerations, and

Battery Module & Pack Manufacturing: Step-by

Apr 19, 2025 · As India and other emerging markets ramp up battery pack assembly, the global blueprint is clear: automation, flexibility, and integrated

EV Lithium Battery PACK Design Process from

Mar 18, 2025 · EV Lithium Battery PACK Design Process: A Comprehensive Guide The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex

BATTERY CELL, MODULE & PACK TESTING

May 26, 2022 · A fully-equipped independent battery testing laboratory can help. You''ll reach the market faster with an instant expansion to test capacity and a broad menu of testing

BATTERY CELL PRODUCTION IN EUROPE: STATUS QUO

Jul 1, 2024 · With 14 million electric vehicles sold and 706 GWh of batery energy installed, the global electric vehicle industry and the associated batery market grew by 35% and 44%,

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · VDMA The VDMA represents more than 3,700 German and European mechanical and plant engineering companies. The Battery Production specialist department is the point of

What Are the 9 Startup Costs for EV Battery Manufacturing?

Jul 24, 2025 · Discover the 9 startup costs involved in EV battery manufacturing. Learn about equipment, raw materials, and operational expenses for success.

Lithium Ion Battery Quality Control | Lithium-Ion

Quality Assurance When Procuring Lithium Ion Battery Systems,High standard quality management for battery production,JB Battery always offering good

The Future of Battery Production for Electric

Sep 11, 2018 · A battery pack consists of multiple battery modules, each of which typically contains 6 to 12 battery cells. Cells are the most cost-intensive

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

How to Write a Business Plan for Lithium Ion Battery Manufacturing

Jul 24, 2025 · How can you write a business plan for lithium ion battery manufacturing in 9 steps? By following a clear roadmap, you can ensure your venture is both profitable and sustainable,

Battery Pack Manufacturing Process

Mar 15, 2025 · In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and future innovations. Whether you''re a

Battery Pack Manufacturing Process

9 steps of the battery pack manufacturing process: BMS testing, cell sorting, cell mounting, battery module resistance welding, laser welding, shell gluing,

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · Battery cell assembly is one of the key steps in the lithium battery module PACK production line. First, the battery cells are combined with

Volvo Construction Equipment invests in battery

Feb 17, 2023 · Volvo Construction Equipment invests in battery pack production at excavator plant in Changwon, South Korea, signalling its sustainability

Industry Information

- Lithium battery supply for Uruguay energy storage power station

- Where is the Moscow communication base station energy management system

- Outdoor base station wind power supply

- Increase the power generation of photovoltaic panels

- Samoa lithium energy storage power wholesale

- Communication base station pet solar panels

- St Johns 1500vdc PV combiner box

- Chisinau Photovoltaic Solar System Manufacturer

- Embedded 48V Inverter

- Chile Energy Group Energy Storage Power Station

- Preliminary design of energy storage capacity scheme

- 5v small solar power system

- Eritrea All-vanadium Liquid Flow Energy Storage System

- Africa EK Vanadium Energy Storage Battery

- Riyadh Flow Battery

- How high is the voltage in a communication base station

- Syrian photovoltaic inverter standards

- Male 24v lithium battery pack

- Budapest high performance energy storage battery

- Quiet current of sine wave inverter

- The latest Syrian energy storage solution

- Customized battery cabinet power supply

- Fixing photovoltaic panels on glass

Commercial & Industrial Solar Storage Market Growth

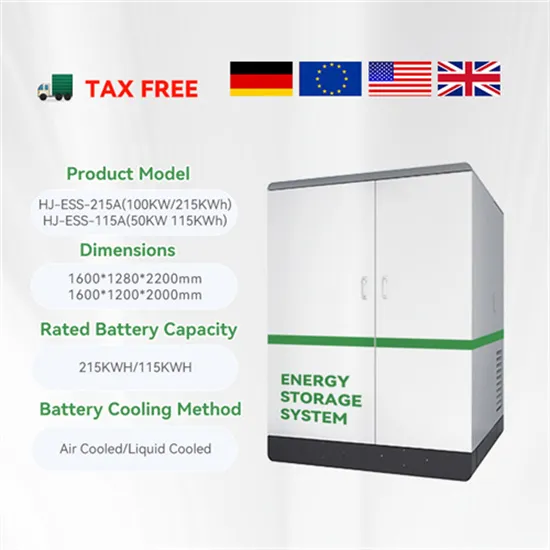

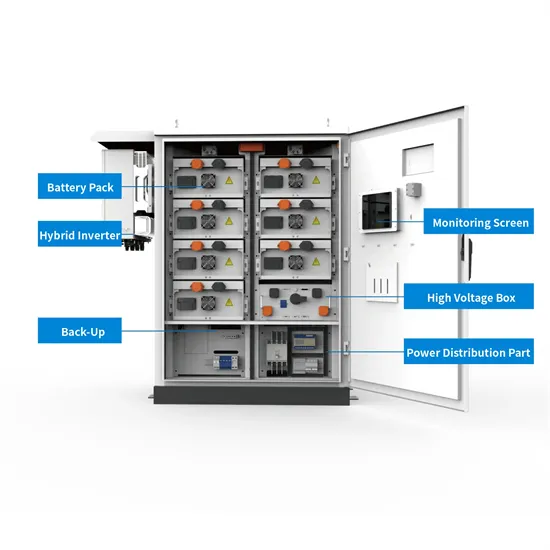

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

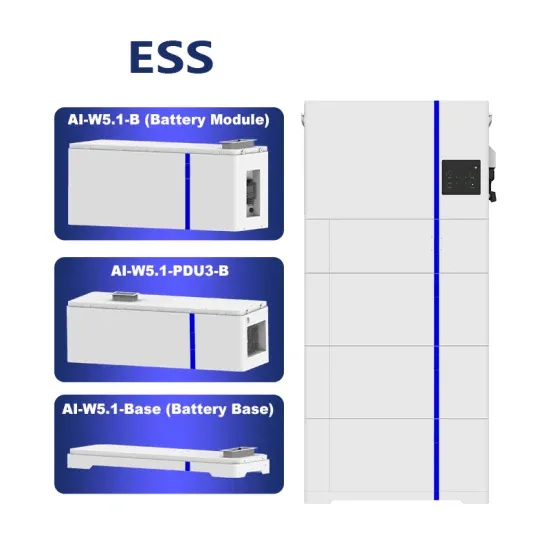

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.