APPLICATION NOTE

Mar 20, 2020 · As per this system, one of the two current-carrying conductors is required to be grounded. This grounded conductor is called the "Neutral / Cold / Return". As this conductor is

Ground Base Station Antenna Design for Air-to-Ground Communications

Mar 22, 2024 · The sixth generation (6G) of mobile communication networks aims to bring innovations in mobile broadband solutions and airborne communications. This paper proposes

Effective grounding in photovoltaic (PV) systems is the creation of a low-impedance reference to ground at the AC side of the inverter--or group of inverters--that is designed to be compatible

Why is the communication power supply -48V?

Jun 16, 2021 · Why is the communication power supply -48V? What is the difference between +48V and -48V? Welcome to Get a Quote: Email:

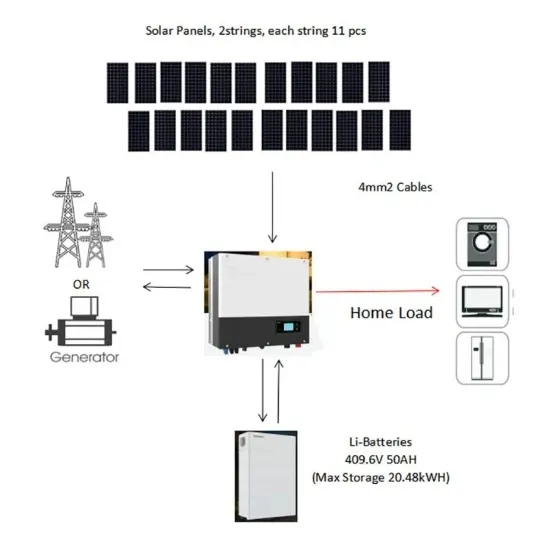

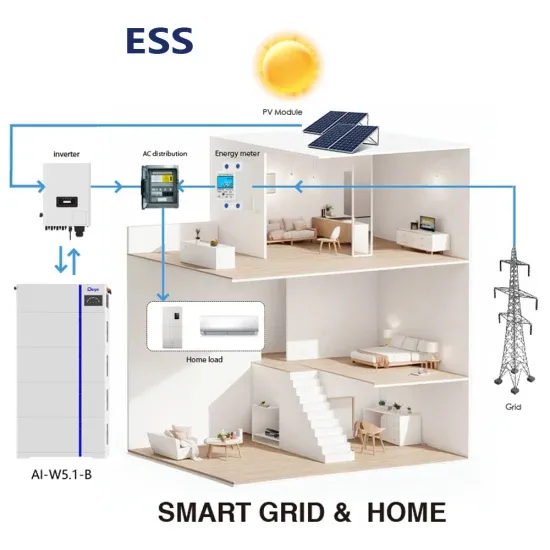

Telecom Base Station PV Power Generation System

Feb 1, 2024 · The communication base station installs solar panels outdoors, and adds MPPT solar controllers and other equipment in the computer room. The power generated by solar

10 common inverter failure and the solutions –

Nov 15, 2023 · This article will give you an overall guide on the reasons of 10 common inverter failure and the solutions step by step to solve these problems.

Positive & Negative Ground Sites

Apr 29, 2020 · OVERVIEW Wireless communications sites and network devices typically operate on 12, 24 or 48 volts DC. For 12 and 24 volt sites, the polarity of these devices are typically

Ground Fault Basics and Inverter Grounding

Feb 12, 2019 · How does the overall system get grounded? It is grounded by means of the Enclosure Grounding Terminal attached to the inverter. Connect

Am I supposed to ground the inverter or the

Jun 26, 2017 · What is the make and model of inverter? Can you link to the installation instructions? Also, I notice that you show a 40A fuse in series with

Communication Base Station Inverter

Dec 14, 2023 · The power requirements of inverters for communication base stations vary depending on the size of the site, equipment requirements and

Grounding and protecting 12V Inverter

Apr 27, 2021 · Before you ask, the inverter documentation just refers to ground the housing to a metal ground of the vehicle (not my case) or the negative pole of the battery, but it says noting

Simulation and Classification of Mobile Communication Base Station

Dec 16, 2020 · In recent years, with the rapid deployment of fifth-generation base stations, mobile communication signals are becoming more and more complex. How to identify and classify

What is Negative Grounding in Solar Inverters?

Jun 16, 2024 · Negative grounding is key to lessening the chance of electrical accidents and damage to your equipment. When we talk about negative

Antenna Tower Grounding: A Step-by-Step

Antenna tower grounding is an important step when installing a tower. It is manly for safety, however, it can improve or eliminate RFI issues.

PV Inverter Quick Installation Guide

Feb 2, 2024 · 4.2 Connecting the PE Cable WARNING Since the inverter is a transformerless inverter, neither the negative pole nor the positive pole of the PV string can be grounded.

USER S MANUAL

May 16, 2024 · NOTE: Never connect the positive or negative poles of the solar equipment to ground. NOTE: This inverter is only compatible with 240V Split-phase grid or generator input.

Common faults and solutions of inverters | Solar Inverter, Inverter

1 day ago · Low insulation impedance, usually due to a short circuit between the positive and negative poles to ground. Excessive leakage current Reason for malfunction: The inverter

Microsoft Word

Dec 10, 2024 · Ground the positive terminal of the battery and move the DC breaker/disconnect from the positive conductor to the now ungrounded negative conductor. This would be like

Grounding a base station antenna

Mar 29, 2023 · What is the best way to ground a base station antenna so my equipment or house isn''t fried by lightening?

What Is Negative Grounding In A Solar Inverter?

Negative grounding in a solar inverter refers to connecting the negative terminal of a solar power system to the ground. The main purpose of negative

Positive Ground Applications

Sep 1, 2008 · The problem with the communications connection in a positive ground system is that the communications is ground referenced - which means it has a connection to the DC

Troubleshoot Ground Fault on

Jun 3, 2019 · If the inverter stops production and the Alarm ID 313-1 (Low Insulation Resistance) or 318-1 (Abnormal Residual Current) is displayed in the Smartlogger1000&2000 or SUN2000

Technical Information

Jun 13, 2025 · A low-impedance ground connection is required so that the devices can fulfill their specified overvoltage category. The standard only takes into account residual currents that

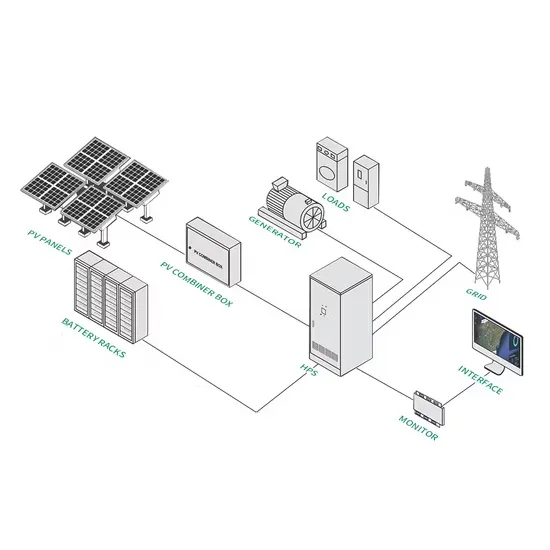

Complete Guide to 5G Base Station

Nov 17, 2024 · A typical communication base station combines a cabinet and a pole. The cabinet houses critical components like main base station

Tower and Base Station Antenna Grounding

Jan 11, 2023 · The lightning protector is connected to a ground or ground plate, which is bonded to the electrical system ground. Inside your house, all of your devices (radios, power supplies,

How to Ground a Photovoltaic Inverter?

Nov 22, 2023 · How to Ground a Photovoltaic Inverter? Grounding a photovoltaic inverter is a preparatory step before making electrical connections. Before

Detailed explanation of inverter communication

1 day ago · Usually, each inverter is equipped with a GPRS/4G data collection module. Through the built-in SIM card, the collected data is uploaded to the

How do I properly ground a 12V off-grid solar

Oct 18, 2023 · I have a 12V DC system I just built (see image below), which I intend to ground to the DC negative side (see dotted green lines) but not quite

How to Ground Solar Inverter

Nov 17, 2023 · Solar inverters can be grounded by using a grounding rod made of copper. Grounding and earthing are crucial for safe and effective inverter installation. They ensure the

How to Ground Solar Inverter

Nov 17, 2023 · How to Ground Solar Inverter: Insert grounding electrode, connect conductor from inverter''s ground terminal.

Grounding schemes for various Inverters

Feb 28, 2025 · Grounding schemes for various Inverters This is a collection of grounding schemes for various inverters. It is a collection of information gathered from hands-on experience,

7. Ground, earth and electrical safety

Jun 17, 2025 · For 6-MPPT inverter: Connect the external fuse component to PV positive connector, then insert the positive connector of the fuse component and negative connector

SG3.0RT / SG4.0RT / SG5.0RT / SG6.0RT / SG7.0RT /

5 days ago · • For negative voltage scheme, after the PID function is enabled, the voltage to ground of all PV strings is lower than 0, and therefore the PV string-to-ground voltage is a

What is Telecommunication Base Station | China

What is telecommunication base station, let''s learn about communication base stations. China telecom equipment supplier.

Proper Base Station & Mobile Grounding

In setting up a base station, placing an 8′ ground rod into the ground directly below the antenna is recommended. Run a #8 solid copper ground wire from

Grounding DC Power Supplies: What You Need

May 3, 2020 · Should you connect a DC power supply to ground or not? The answer is not a straightforward yes or no. This article explores the benefits

How to Ground a Inverter

How to ground the inverter: There is a terminal on the rear panel of the Giandel power inverter marked "Ground" or " ". This is used to connect the chassis of

Microsoft Word

Dec 10, 2024 · A system comprising multiple charge controllers and multiple inverters requires double-pole breakers on both positive and negative conductors of all DC power conductors,

6 FAQs about [How to ground the positive pole of the communication base station inverter]

How do you connect a copper grounding rod to an inverter?

A copper grounding rod must be driven into the ground outside and connected to the single grounding point using a thick copper grounding wire. The electrical distribution panel is ideal for having a single grounding point. You must understand the differences between the following ground points used in Inverter installations:

How do you ground an inverter?

It is grounded by means of the Enclosure Grounding Terminal attached to the inverter. Connect a 6 AWG wire from the enclosure Grounding Terminal to any convenient Earth Ground point that includes: a metal water pipe, a ground rod, or other large metal mass that is partially buried in earth.

Do inverters have a grounding point?

Some modern inverters are fitted with a grounding point connection in the inverter circuitry. Still, this grounding point must be disconnected when the inverter is connected to a power distribution panel with its grounding. The inverter must not be double grounded as this may cause a problem.

Does an RV inverter need a grounding point?

Your RV power system’s components must have a single, unified grounding point on the RV’s chassis. For proper installation, it is essential to connect the solar panel, battery bank, and inverter to a single grounding point. Also Read: Should An RV Inverter Be Left On When Plugged In?

Do inverters have a grounding wire?

Inverters are enclosed with an Aluminum heatsink to dissipate heat and are also fitted with a grounding terminal to the enclosure. A grounding wire of 6 AWG must be connected to the grounding terminal on the inverter and connected to a single-point grounding connection wire.

What is negative grounding?

When the negative terminal is connected to the Earth, it can be referred to as negative grounding. Negative grounding of the inverter has many benefits. It does connect with the electrical system of the home and it provides a separate earth ground. It helps when there is extra voltage in the circuit and it prevents the damaging of appliances.

Industry Information

- High quality China 500 watt solar inverter Factory

- Battery Energy Storage Growth Funding

- Which companies have energy storage power stations in Barcelona Spain

- Berlin EK Photovoltaic Power Inverter

- How much does the Nassau energy storage system cost

- 50W Solar Garden

- Huawei Victoria Portable Outdoor Power Supply

- 25kW PV grid-connected inverter

- Single-phase inverters are all off-grid

- National energy storage container prices

- The largest photovoltaic glass factory in Cordoba Argentina

- Energy storage cabinet assembly report

- Budapest Energy Storage Cabinet Battery Factory

- How big can a 1 kilowatt solar panel be

- Communication energy storage base station battery

- Energy storage cabinet supply in Portugal

- Kigali Super Farad Capacitor Company

- Outdoor power supply accessories manufacturers

- Communication Base Station EMS Weekly Report

- Does the folding chair rely on a portable power source

- Whether the energy storage cabinet battery is a state-owned enterprise

- Which battery cabinet companies are there in Tbilisi

- Diversification of new energy storage

Commercial & Industrial Solar Storage Market Growth

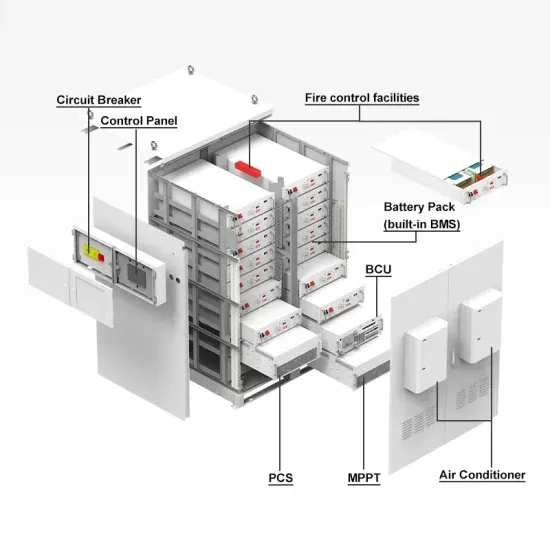

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.