UV Curing Systems in Photovoltaic Manufacturing

Jan 29, 2024 · Understanding UV Curing in Photovoltaic ManufacturingEncapsulation Process: UV curing is prominently utilized in the

Degradation and Failure Modes in New

This detailed analysis by Task 13, provides essential insights into the reliability and performance of cutting-edge photovoltaic technologies, focusing on the

UV Curing Systems in Photovoltaic Manufacturing

Jan 29, 2024 · UV curing systems offer unparalleled curing speed, significantly reducing production cycle times and increasing throughput in PV

CN112389949A

The invention discloses a solar photovoltaic module curing line conveying system which comprises a curing conveying line, wherein the curing conveying line consists of chain plates,

Advanced analysis of ethylene vinyl acetate copolymer

Mar 1, 2024 · Ethylene vinyl acetate (EVA) copolymers are commonly used as encapsulation material and as adhesive layer for backsheet laminates of photovoltaic (PV) modules. While

Photothermal Stability of Various Module Encapsulants

Aug 8, 2013 · The results indicate that the photothermal stability of two foreign ethylene vinyl acetate (EVA) films is dependent on the formulation, curing method and condition, as well as

Insights into the Encapsulation Process of Photovoltaic

Aug 14, 2024 · Appropriate encapsulation schemes are essential in protecting the active components of the photovoltaic (PV) module against weathering and to ensure long term

The performance and durability of Anti-reflection coatings for solar

Sep 1, 2023 · Abstract Solar photovoltaics (PV) is an important source of renewable energy for a sustainable future, and the installed capacity of PV modules has recently surpassed 1TWp

Lecture 17 Solar PV Cells Modules

Feb 25, 2020 · Solar PV Cells and Modules Prof. C.S. Solanki Department of Energy Science and Engineering [email protected]

Investigating the reliability of electrically conductive adhesives

Mar 1, 2022 · The ECA bonding method is more environmentally friendly than the conventional soldering process that uses lead, and can reduce the thermal stress in the cell, as the curing

Review of degradation and failure phenomena in photovoltaic modules

May 1, 2022 · Secondly, a summary of the main stress factors and how they influence module degradation. Finally, a detailed review of degradation and failure modes, which has been

Investigation of the curing state of ethylene/vinyl acetate

Jul 1, 2016 · The cure behaviour of a specific ethylene vinyl acetate material as used for encapsulation of photovoltaic modules was analysed by rheometer, differential scanning

PVI19_Front_Cover dd

May 21, 2024 · PV module set-up the longest cycle time. The main goal of Crystalline silicon (c-Si) PV modules Production process equipment producers is to decrease the typically consist of a

Enhancing photovoltaic modules encapsulation: Optimizing

Apr 1, 2024 · It acts as a protective layer, preventing moisture ingress, mechanical damage, and environmental degradation. Ensuring the long-term reliability and performance of PV modules

Advanced polymer encapsulates for photovoltaic devices −

Sep 1, 2021 · This situation is evidencing the urgent need of the alternative sustainable energy resources [3]. Solar energy is the most-abundant renewable energy-resource and among the

Thermomechanical residual stress evaluation in multi

May 1, 2019 · Photovoltaic (PV) module reliability issues, due to silicon cell cracking, are gaining more and more attention due to increasing demand for solar power and reduction of cell

Influence of Lamination Conditions of EVA

Oct 29, 2023 · Then, based on some specification limits on the curing degree, the optimal lamination time for solar modules can be determined at different

Properties and degradation behaviour of

Aug 21, 2020 · Different encapsulation films show comparable optical, thermal and thermo-mechanical properties. Only shear viscosity values are higher for

(PDF) Effect of humidity on photovoltaic

Dec 1, 2015 · This paper presents the impact of relative humidity on the output of a solar Photovoltaic (PV). The relative humidity has influences on the other

Degradation Processes and Mechanisms of Encapsulants

Jan 1, 2019 · In order to model PV module degradation effects, it is necessary to understand them not only on a macroscopic level by monitoring the power loss, but also to investigate the

The environmental factors affecting solar photovoltaic output

Feb 1, 2025 · Finally, long-term changes in solar irradiance, driven by climate change and air pollutants, present future challenges for maintaining PV efficiency. Optimizing PV systems for

Analysis of solar cells interconnected by electrically

Aug 1, 2019 · Graphical abstract Interconnection of solar cells by an electrically conductive adhesive (ECA) can replace the use of conventional metal ribbon connections for photovoltaic

The effect of storage conditions on the long-term stability of

Oct 15, 2023 · We evaluate the effect of storage conditions of uncured encapsulant rolls and the potential consequences on photovoltaic (PV) module performance. We s

EFFECT OF LOWERING CURING TEMPERATURE OF

Sep 27, 2024 · ontent effect on volume resistivity, joint resistance, module performance and interconnection reliability. Silver consumption in PVST module was estimated to be 168 mg

Influence of Lamination Conditions of EVA

Oct 29, 2023 · Encapsulation is a well-known impact factor on the durability of Photovoltaics (PV) modules. Currently there is a lack of understanding on the

Effects of the Curing Process on the Residual Stress in

Aug 31, 2023 · The effects of curing process parameters (elastic modulus and thickness of silicone rubber, and curing temperature) on residual stress in a solar module have been

The thermo-mechanical degradation of ethylene vinyl acetate

Jul 1, 2016 · The thermal ageing of an ethylene-vinyl acetate (EVA) polymer used as an adhesive and encapsulant in a photovoltaic module has been investigated. The EVA is used to bond the

The causes and effects of degradation of encapsulant

Jan 1, 2018 · Photovoltaic (PV) modules are subject to climate-induced degradation that can affect their efficiency, stability, and operating lifetime. Among the weather and environment

Photothermal Stability of Various Module Encapsulants

Aug 8, 2013 · ABSTRACT This paper briefs the photothermal reliability studies we conducted on different encapsulation materials for some U.S. PV companies that are subcontractors of the

Hotspot Effect on Solar Panels: Causes and

Feb 13, 2025 · As PV module technology advances to thinner wafers, which are prone to producing micro-cracks throughout the processes of production,

Photovoltaics International PV module testing – how to

May 21, 2024 · Photovoltaics International PV module testing – how to ensure This paper first appeared in the thirteenth print edition of the Photovoltaics International journal, published in

36th European Photovoltaic Solar Energy Conference

EFFECT OF CURING TEMPERATURE ON PROPERTIES OF ETHYLENE VINYL ACETATE (EVA) USED FOR CRYSTALLINE SILICON SOLAR MODULE ENCAPSULATION Baloji

(PDF) EFFECT OF CURING TEMPERATURE ON

Feb 10, 2020 · Here we have investigated the effect of curing temperature on gel content, transmittance, resistivity, adhesion strength, and thermal

PhotoVoltaic Lamination Process | Luc

Nov 30, 2022 · This text provides an overview of the PhotoVoltaic lamination process. It examines the differences between various types of laminators, and

6 FAQs about [Solar photovoltaic module curing effect]

What happens during PV module encapsulation?

Samples of 5 mg of a During the PV module encapsulation complex chemical reactions are expected commercially available fast-cure EVA process a crosslinked polymeric matrix to take place during the curing step.

What is PV encapsulation?

Appropriate encapsulation schemes are essential in protecting the active components of the photovoltaic (PV) module against weathering and to ensure long term reliability. For crystalline cells, poly(ethylene-co-vinyl acetate) (EVA) is the most commonly used PV encapsulant.

Why do photovoltaic modules need elastomeric encapsulation material?

According to Czanderna and Pern, the encapsulation material has to be elastomeric to prevent the photovoltaic module from overstressing and cracking due to mismatched thermal expansion coefficients .

How are photovoltaic modules made?

Photovoltaic modules are manufactured in a lamination process during which the EVA encapsulant is molten during heating under simultaneous application of a vacuum to remove air and water vapour from the module, with chemical cross-linking initiated at a certain temperature to make the material shape-persistent and insoluble.

What factors affect the reliability of advanced solar technology?

“The new report, Degradation and Failure Modes in New Photovoltaic Cell and Module Technologies, highlights key factors that impact the reliability of advanced solar technologies,” said Marc Köntges, a leading author of the report. “We identified common failure mechanisms and provide insights to improve long-term reliability and efficiency.

What is the difference between TDU and PV module encapsulation?

The VOCs produced is the PV module optimize the encapsulation process, TDU was operated in splitless mode. encapsulation process is discussed. based on GC-MS study of the chemical The TDU temperature program for processes occurring during PV module extraction was 20 °C (hold for 2 min), encapsulation17-20.

Industry Information

- High temperature of outdoor base station

- Working principle of Huijue energy storage battery cabinet

- China drawout circuit breaker in Chicago

- Solar panel photovoltaic water pump

- How much v is good for home energy storage

- Cheap new circuit breaker for sale Price

- What are the photovoltaic power generation and energy storage systems in Ecuador

- Factory price 2 4 kw inverter in Congo

- Wholesale switchgear controls in Sydney

- Operation and maintenance costs of Moscow distributed energy storage power station

- Huawei independent energy storage project plan

- European backup UPS uninterruptible power supply

- Affordable home energy storage in East Asia

- Latest ranking of solar inverters

- Northern Cyprus Energy Storage Base Station Project Bidding

- Liquid-cooled energy storage battery cabinet manufacturer in Bolivia

- Lifespan of home inverters

- LTE Base Station Site Deployment Scenarios

- A shopping mall in Bern that sells outdoor power supplies

- Manama inverter 5kw single phase

- Burkina Faso photovoltaic conductive glass manufacturer

- Marseille Sunshine Grid-connected Inverter Price

- Battery that can store 100 kWh of electricity

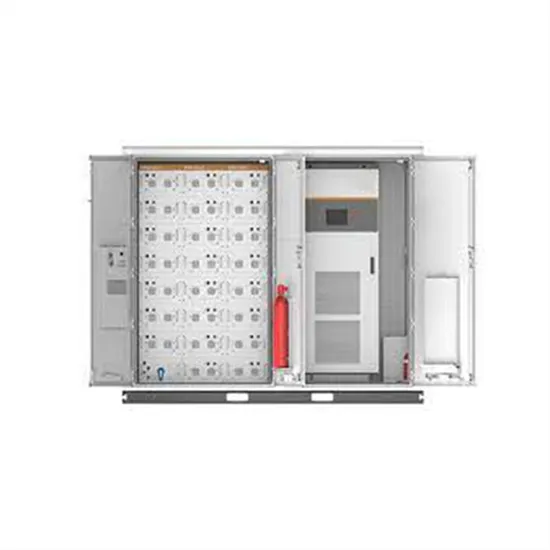

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.