Complete Guide for Battery Enclosure

May 29, 2024 · Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

Battery Module Assembly Line: Key Technologies, Challenges

Jul 24, 2025 · A battery module assembly line is a specialized production line designed to manufacture and assemble the various components of battery modules. These modules are

Top 10 Battery Assembly Line Equipment

Mar 23, 2025 · Discover the top 10 battery assembly line factory manufacturer suppliers for 2025. Learn how to select the best equipment for your production

Assembly lines for battery systems

2 days ago · AKE technologies represents the system partner in the field of assembly of e-mobility components for its customers. We offer our customers

Assembly line for battery modules and battery packs

3 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Optimize Battery Assembly Line with Design and

4 days ago · A battery assembly line is a system that puts together different parts of a battery, like cells, tabs and modules, into a complete unit. It uses machines, robots and automation to

Energy Storage Assembly Line: The Backbone of Modern

Jun 18, 2020 · a factory humming with robotic arms, conveyor belts stacked with lithium-ion cells, and engineers fine-tuning battery packs faster than you can say "renewable energy." Welcome

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · Explore the Lithium-Ion Battery Assembly Line —how precision, automation, and testing ensure high performance, safety, and reliability in

Battery Assembly Line Design, Build, and Scaling

We design and implement fully integrated battery assembly lines that streamline module and pack production, ensuring precision, consistency, and scalability.

Prismatic Battery Pack Assembly Line

The Prismatic Battery Pack Assembly Line integrates a variety of automated equipment and technologies, mainly covering the entire process from module assembly to the final battery

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Advanced Lithium Battery Pack Automated

Discover the state-of-the-art automated assembly production line system for lithium battery packs, designed for new energy applications. This 16-meter

Automatic Lithium Battery Assembly Line Explained

Learn how automatic lithium battery assembly lines boost productivity, safety, and quality for EVs and energy storage in India''s growing battery manufacturing sector.

Manufacturing Intralogistics Concepts for a Battery Assembly Line

Dec 18, 2024 · This paper designs intralogistics concepts for an electrical battery pack production setup inspired by our industry partner, featuring automated and manual work

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · Production Line The production line for lithium battery packs is a highly integrated system designed to streamline the manufacturing process

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · Introduction The battery pack assembly process is a cornerstone of modern manufacturing, essential for producing high-performance battery

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Li-ion battery technology has become preferred technology in many battery storage applications due to its relatively high energy and power density, better volumetric and

Battery Assembly Line

Jul 18, 2025 · Battery Assembly Line: Components, Processes, and InnovationsA battery assembly line is a highly automated production system designed to manufacture batteries

TWS ESS Battery Solutions-2023-0223

Jun 21, 2023 · TWS, a dynamic and global industry leader focused on providing innovative Lithium-based battery technology solutions, was founded in 1998. With 25 years development,

Unveiling Prismatic Battery Fabrication

Aug 18, 2023 · The technology-driven production process, from electrode coating to pack assembly, ensures that prismatic batteries are efficient, reliable, and

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · Lithium-ion Battery Module and Pack Production Line Process Flow The lithium-ion battery module and pack production line is a complex

Power Battery Assembly Line : From

Jan 15, 2025 · A power battery assembly line is a specialized manufacturing setup that transforms raw materials and components into fully functional

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Battery Pack Manufacturing Process: Step-by-Step Guide

Dec 2, 2024 · Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

Turnkey lines for battery pack technologies

Turnkey lines for battery pack technologies Solutions for battery pack technologies We offer modular and flexible solutions to cover many fields,

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a

Assembly Line – TBS Engineering

2 days ago · Our assembly line incorporates cutting-edge technology, ensuring a seamless and advanced process. From enveloping and stacking to COS, inter

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · Production Line Overview Chisage ESS has been in the field of solar battery for many years and is committed to producing high-quality energy

C & D Technologies | Stationary Battery Cabinets

C&D battery cabinets and enclosures Battery cabinet solutions for pure lead agm batteries From the industry leader in data center backup batteries, C&D now

Battery Production | AVL

Aug 18, 2025 · To ensure that batteries deliver optimal performance over the longest possible lifetime while meeting strict safety standards, we have developed the AVL Battery TS™ End

Intelligent Battery Pack Assembly Line for Ess Cabinets with

Jul 19, 2025 · This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Battery Assembly Line

Jul 18, 2025 · Below is a detailed overview of battery assembly lines, including their components, processes, and key innovations. 1. Overview of Battery Assembly LinesBattery assembly lines

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Innovating battery assembly

Aug 13, 2025 · Driving the future of electric vehicle battery production The world of electromobility and battery manufacturing is rapidly evolving, and the highly diverse battery manufacturing

Battery ''Module & Pack'' Assembly Line Now

Feb 10, 2021 · The Module and Pack assembly line is the first of UKBIC''s innovative battery manufacturing equipment – sourced and supplied from

4 FAQs about [Battery cabinet assembly line technology]

What makes the cell-to-battery assembly line unique?

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability.

What are the technical parameters of intelligent battery pack?

Intelligent battery pack finished product handling and packaging system. 3: Technical Parameters: Total production line length: 16 meters. Production capacity: Up to X battery packs per hour (customizable). Precision level: ±0.1mm positioning accuracy. Processing efficiency: 99.5% uptime.

What is the final stage of a battery test?

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety.

What is a battery management system (BMS)?

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells.

Industry Information

- Communication base station backup power supply 4850

- Small solar inverter in China in Greece

- Does energy storage include wind power

- Energy storage battery container system design

- Myanmar AC Uninterruptible Power Supply Model

- 5kw on grid inverter for sale in Kenya

- Photovoltaic power generation curtain wall quotation

- Tool battery 5 contacts

- Swiss Energy Storage Power Station Project

- Imported DC inverter

- Huawei uninterruptible power supply alternative

- North Asia wind power generation system was built in

- How many amperes of lithium battery should be equipped with the inverter

- Honduras Energy Storage Fire Fighting Solution

- Outdoor power supply 220v large capacity set

- Doha backup ups uninterruptible power supply sales

- 100ah power station for sale in Tanzania

- How to make profits from grid-side energy storage power stations

- Cheap China furnace circuit breaker Price

- Dynamic energy storage system management system

- Huawei Gabon Centralized Inverter

- Solar powered house generator in Vietnam

- Wholesale al hamad switchgear in Iraq

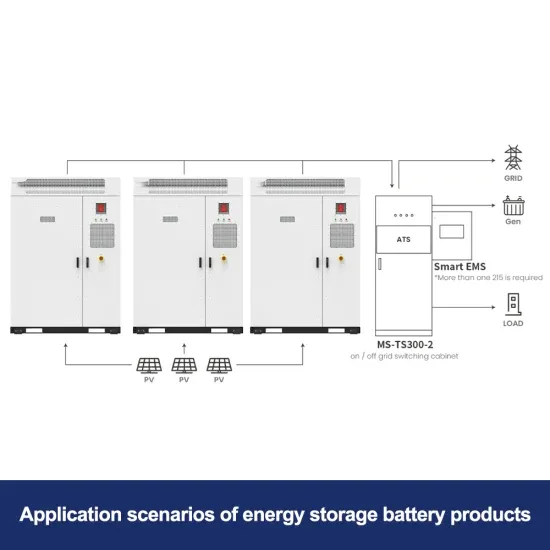

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

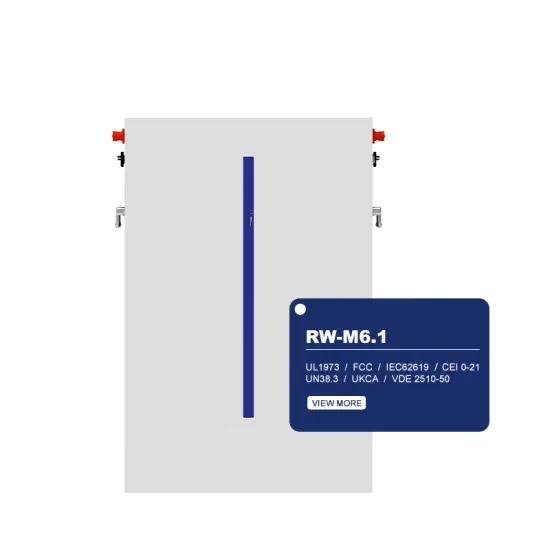

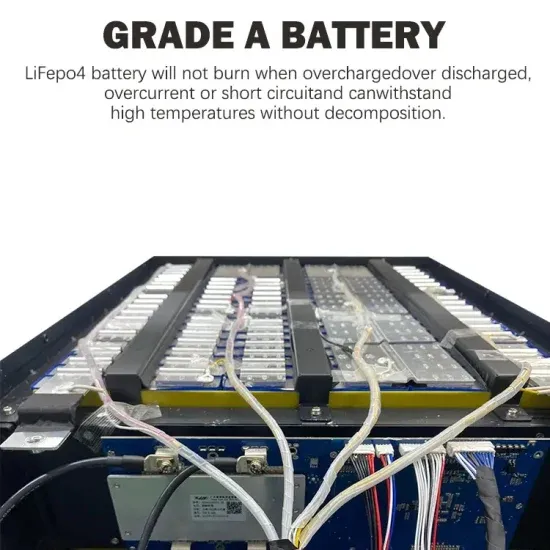

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.